Bamboo vs. Steel Scaffolding: A Comprehensive Guide to Safety, Cost, and Sustainability

Aug 14, 2025

Introduction

Every modern project, regardless of scale (i.e., from a vertical tower to a small house), requires scaffolding. Today's world may suggest that steel is the contemporary way to build structures, but bamboo is certainly more traditional, yet is commonly used throughout most of the world. It is not about normal practice versus modern practice; it is about the possibilities for engineering, safety, and costs when the material is different.

This paper provides a comparative representation of bamboo and steel scaffolding in terms of advantages, disadvantages, and best uses, which is delivered for the purpose of providing the construction professional, project manager, or engineer with the information to make a useful decision based upon their project information, safety, and sustainability.

The Application and Characteristics of Bamboo Scaffolding

Bamboo has been a primary building material across Asia for hundreds of years. The extensive use of bamboo (often in urban environments with the highest population levels, such as Hong Kong) relates a great deal to the intrinsic material properties of bamboo and certainly many, many skills by many successful builders.

Structural and Mechanical Properties: Bamboo, in detail, has a strength-to-weight ratio that's better than nearly any other material. Specific bamboo species have recorded tensile strength equivalent to steel! While bamboo is an incredibly strong material, it is also very lightweight, which not only allows for quick manual handling and assembly without the need for lifting equipment but is also an advantage in many logistical contexts where organic materials might reasonably be used.

Cost and Economic Factors: The most significant economic advantage of bamboo is its low material cost and its local availability in many places where bamboo can be implemented. So a bamboo project will have a lower up-front project cost. Furthermore, assembly only requires the use of skilled labour as opposed to expensive machine use, which is an additional advantage for any budget-conscious regime that considers future ongoing maintenance costs.

Sustainability Profile: Bamboo adds to the sustainability discussion as a biomass-based material, as it is a renewable material, it has a very fast growth cycle, and is inexpensive to harvest. In addition, bamboo uses the least operational energy and material resources as it provides the most ideal carbon footprint over its life cycle (compared to any other construction material production methods, along with operational energy).

Though bamboo scaffolding has benefits, bamboo scaffolding has disadvantages as well. Developments in safety and structural stability depend on the quality of raw material as well as the knowledge and skill of the team constructing the scaffolding. Given the lack of a grading system for bamboo as well as the unpredictable and uncertain nature of climate hazards (moisture and pests), it is hard to predict both performance and safety.

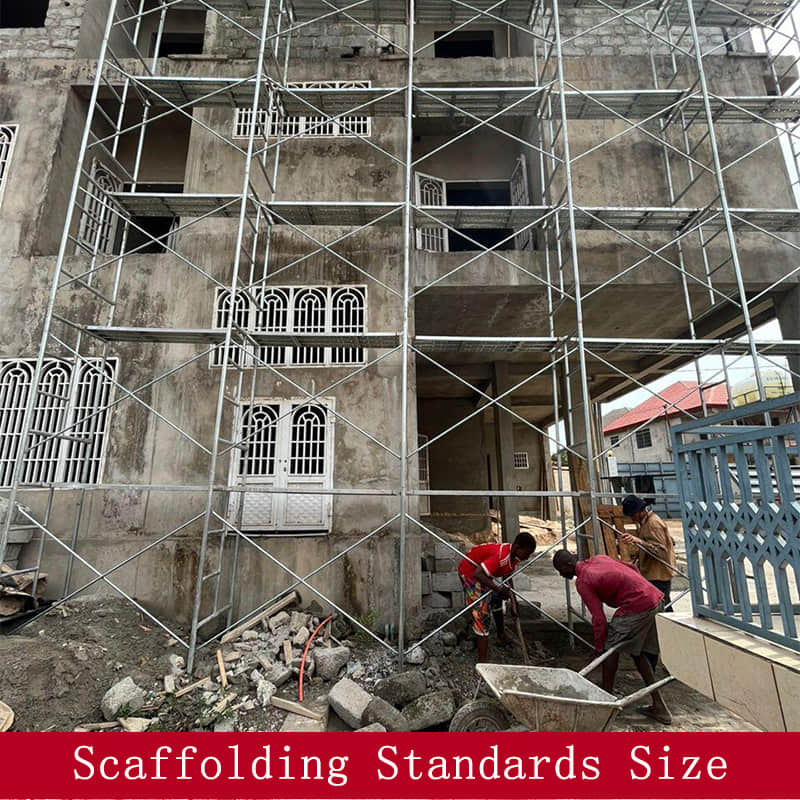

The Integration and Advantages of Steel Scaffolding

The ubiquity of steel scaffolding as the construction community's standard in contemporary building is undoubtedly attributable to steel scaffolding systems meeting the stringent requirements of safety and engineering standards.

Safety and Engineering Standards: Steel scaffolding systems are produced and engineered to the international standards (i.e., OSHA, EN 12810). Each piece is rated for a specific load, ensuring predictable, constant, and stable units to work on. This standardization is paramount when working in high-risk settings and conditions, and when working in multi-storey.

Durability and Reusability: Steel is a durable material and inherently rot-, pest-, and fire-resistant. A well-cared-for steel system can be reused for decades, which affords a very good return on investment. This long lifetime makes steel a good economic option; a consideration for companies involved in longer-term construction operations.

Modularity and Consistency: Because steel scaffolds are modular in design, all components cannot only fit together uniquely but also constitute consistent parts. This consistency removes the uncertainties posed by natural materials with respect to structural reliability, no matter how complex or geographically challenging the project may be.

Flexibility: Steel systems may be designed to virtually any specification consistent with the other types of architectural designs. These designs can also integrate advanced safety features such as guardrails, toe boards, and protective netting, which are necessary for modern, compliant safety features.

Metal scaffolding’s biggest disadvantages are its high upfront cost and weight. Because of the material cost, the initial capital outlay is higher. The weight of steel properly erected must usually be transported and set up on scaffolding. This means there is more equipment cost associated with the scaffold, and the logistics and complexity of the project can and will exceed that of the scaffolding.

Comparative Analysis: A Head-to-Head Evaluation

The following table provides a direct comparison of key attributes to facilitate a comprehensive understanding of the two systems.

Feature

Bamboo Scaffolding

Steel Scaffolding

Safety & Structural Integrity

Dependent on material quality and craftsmanship, non-standardized.

Engineered to strict international standards, offers predictable and reliable stability.

Cost Implications

Lower initial material and labor costs. Long-term costs may increase due to frequent replacement.

Higher initial capital expenditure. Provides greater long-term value through durability and reusability.

Durability & Lifespan

Short lifespan; vulnerable to environmental degradation and pests.

Exceptionally durable; designed for extended service life and repeated use.

Weight & Logistics

Lightweight and easily handled manually; logistically simple.

Heavy and bulky; requires mechanical assistance for transport and assembly.

Assembly & Disassembly

Rapid, manual assembly by skilled workers.

Slower, methodical process requiring trained personnel and adherence to protocols.

Sustainability Profile

Highly sustainable due to rapid growth and minimal processing.

Durable and recyclable; however, its production is energy-intensive.

Optimal Application

Low-rise, short-duration projects in regions with skilled labor and material availability.

High-rise, large-scale, long-term, and complex projects with stringent safety and regulatory requirements.

Conclusion

The choice between bamboo and steel scaffolding is a critical strategic decision that must be guided by a thorough analysis of project specifications and operational constraints. Neither material is inherently superior; rather, each offers a distinct set of advantages tailored to specific contexts.

Bamboo scaffolding is a practical and reasonable choice for work completed where the primary factors are cost and speed (assuming that there are appropriate local building regulations and a skilled workforce). It is most appropriate for smaller, limited work where its unique capabilities can be realized.

Steel scaffolding is the only option for any work where safety, durability, and compliance with legal obligations are the most important factors. It is the only answer for high-rise construction, infrastructure projects on a grand scale, and any other work where the integrity of the structure cannot be sacrificed.

Ultimately, the selection of scaffolding material should be an informed decision, balancing economic factors, environmental considerations, and, most importantly, the imperative of ensuring a safe and secure working environment.

FAQ

1. Is bamboo scaffolding safe?

Yes, bamboo scaffolding can be safe when installed by skilled workers using high-quality materials and adhering to traditional practices. However, its safety is not standardized by international engineering codes, making it less predictable than steel scaffolding. Its structural integrity can be compromised by weather and material inconsistencies.

2. Is steel scaffolding more expensive than bamboo?

Initially, yes. The upfront cost for steel scaffolding materials and professional installation is significantly higher than for bamboo. However, steel scaffolding is a more cost-effective long-term investment due to its reusability, durability, and minimal maintenance needs, which can save money over the life of multiple projects.

3. What about the environmental impact of each material?

Bamboo is highly sustainable as a rapidly renewable resource with a low carbon footprint. Steel's production is energy-intensive, but its sustainability comes from its exceptional durability and 100% recyclability. A single steel system can be used for decades, reducing the need for constant material replacement.

4. Can steel and bamboo scaffolding be used together?

While it's technically possible, it is not a common or recommended practice. Combining two fundamentally different systems—one standardized and engineered, the other traditional and non-standardized—can introduce unpredictable risks and complicate safety assessments. It is best to use one system consistently for a given project to ensure structural integrity and compliance with safety protocols.