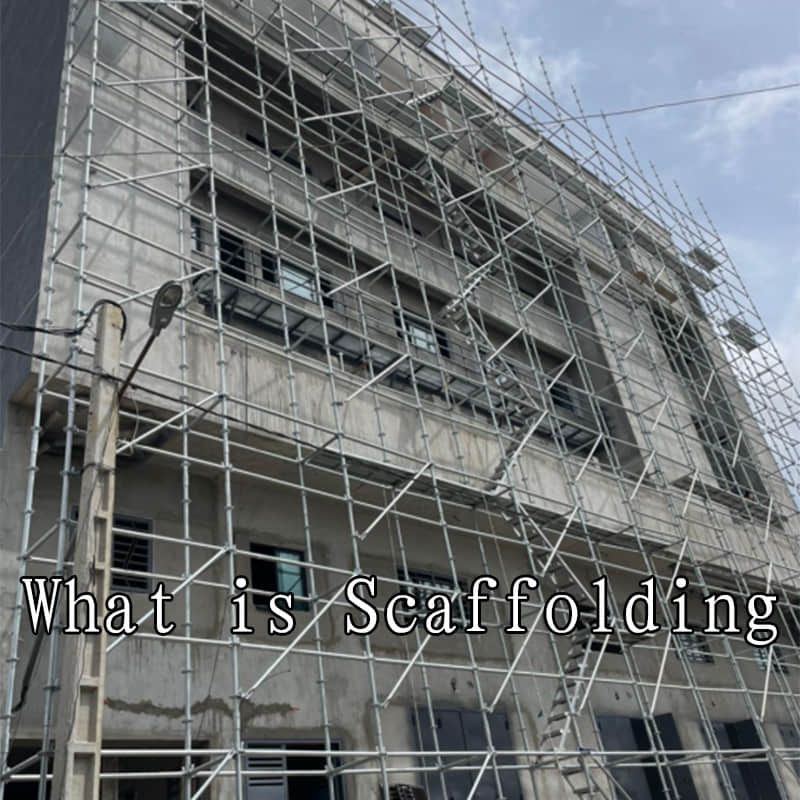

Quick Guide: What is Scaffolding?

Jun 20, 2025

Scaffolding is commonly used in the construction industry. It is a temporary elevated structure used to provide construction workers with a safe working platform. Scaffolding is assembled on the ground and adjusted to the shape of the building. It is strong enough to support workers, tools, or equipment, and heavy materials during construction, demolition, repair, or maintenance.

Scaffolding Systems Components

● Standards (or Uprights): The vertical tubes that take the load down into the ground.

● Ledgers: A horizontal tubes that connects the columns and extends along the length of the scaffold.

● Transoms: The horizontal tubes that run across the width of the scaffold and connect the standards together. Most transoms are located underneath the working platforms of scaffolding.

● Braces: Installed at the diagonal of the scaffold to enhance the stability of the scaffold structure.

● Base Plates: The flat plates at the base of the standards help to spread out the load over a larger area.

● Working Platforms (or Boards): The wooden or metal planks that provide the working or walking area for workers.

● Guardrails or Toeboards: Safety features on the working platforms that help to avoid falls of workers or objects.

These components are typically made from steel, aluminum, or timber, chosen for their strength, durability, and reusability. The way they are connected varies depending on the type of scaffolding, but the aim is always to create a rigid and secure framework.

The Benefits of Scaffolding

Scaffolding offers a multitude of benefits that are indispensable to the efficiency, safety, and quality of work on elevated structures:

● Enhanced Safety: Scaffolding supplies workers with a stable, flat, and secure working surface, which greatly reduces the chance of falls. Increased safety is realized with guardrails, toeboards, and secure decking.

● Improved Access: With scaffolding access, workers have the capability to reach not only the high areas which would otherwise be unreachable on the exterior or interior of a building, but also access to the building surface is improved.

● Increased Productivity: With a fixed and stable work platform, workers can complete tasks in a more efficient manner. Workers can easily transition from the movement of ladders or other temporary supports, which makes it easier for the worker to have access to tools and supplies.

● Support for tools and materials: Scaffold systems are designed to have a working load for both employees, but can also be designed to support heavy materials like bricks, mortar, and tools.

● Flexibility: Scaffold systems can be built for almost any size or shape of building.

● Inspection of Work: Access to all parts of the structure at height will provide for easier inspections and therefore better control of the quality of work.

● Temporary Storage: Scaffolding is a convenient temporary storage area for materials and tools that need to be placed, organized, and made convenient for the worker.

Scaffolding Types

Supported Scaffolds: The most common type, these platforms are supported from below by rigid load-bearing members.

Frame Scaffolding: Widely used for smaller to medium projects, consisting of pre-fabricated frames, cross braces, and planks for quick assembly and dismantling.

Tube and Coupler Scaffolding: Highly versatile and heavy-duty, ideal for complex structures, using individual tubes connected by couplers for custom configurations.

System Scaffolding: Uses pre-engineered components with fixed connection points (e.g., Kwikstage, Ringlock), offering faster assembly and consistency with good versatility.

Trestle Scaffolding: Simple and portable, mainly for indoor work at lower heights, with platforms supported by movable trestles.

Cantilever Scaffolding: Used when ground support is unavailable, built on beams projected from the building, requiring careful engineering.

Suspended Scaffolds: Platforms that are suspended from ropes or cables from the overhead structure, which can usually be adjusted, are generally used for high-rise maintenance and window cleaning.

Mobile Scaffolds: a supported scaffold with wheels or casters, that allows it to be moved manually. This type of scaffold is used when a task will be done more than once, or often; however, they have to be used with extreme caution to avoid unintentional movement.

Dangers of Working on Scaffolding

Falls from height:

• No guardrails or improper guardrails

• Slippery platform (due to rain, ice, or debris)

• Loose or improper use of unsecured planks

• Overreaching or improper use of personal fall arrest systems

Scaffold collapse:

o The scaffold is being improperly erected by unqualified personnel

o The scaffold is being overloaded by either personnel or materials, above rthe ated capacity for the scaffold

o The scaffold being improperly braced or tied to a structure

o Damaged parts

o Foundation not able to support, weak or unstable

• Falling objects: People being struck by tools, materials or debris falling from a scaffold can lead to serious injury. The use of toeboards, netting, and tool lanyards reduces the likelihood of this occurring.

• Electrocution: Scaffolds can become energized if metal scaffolds contact overhead power lines or other uninsulated electrical equipment. Keep safe distance away from power lines.

• Weather Conditions: High winds can affect scaffolds that are not tied to the building. Ice and snow will make the platforms slippery.

• Improper Access: Falls are caused by workers using ladders that are unsecured or climbing on structures of the scaffold that are not meant for climbing.

• Failure to Inspect and Maintain: Scaffolds that have not been inspected for damage or to ensure it has been assembled correctly are unsafe. Nuts and bolts can become loosened by wind and rain, and the scaffold could also be unsafe due to the above factors.

To have a hope of reducing these risks, nothing less than full compliance with safety regulations, proper training of all persons involved in raising and using the scaffolds, and performing regular inspections is required.

Uses of Scaffolding

Scaffolding is multi-purpose in its ability to be utilized in many industries and applications:

Construction:

Bricklaying and Masonry: providing a means for a mason to work efficiently at different heights.

Steel Erection: provides an elevated working area for erecting and tying together the steel frame of a new building.

Concrete: to allow access for the support of the formwork, and other facets of construction, and to allow the ability to pour and finish a concrete project.

Roofing: to provide a safe access point along a roofline to follow through with the installation of a roof and/or completion of repairs.

Cladding and Glazing: providing means of access for installing the building façade, window installation, or curtain walls.

Renovation and Restoration:

Façade Cleaning and Repair: Safely reaching and working on building exteriors.

Repainting and Plastering: Enabling a consistent finish across large surfaces.

Window Replacement: Providing a stable platform for removing old windows and installing new ones.

Industrial Maintenance:

Equipment Installation and Repair: Providing access to large machinery and pipework.

Insulation Work: Enabling the application or repair of insulation on pipes and vessels.

Boiler and Tank Maintenance: Allowing workers to access confined or elevated spaces within industrial facilities.

Shipbuilding and Aerospace: Used for constructing, maintaining, and repairing large vessels and aircraft.

Event Staging: Temporary scaffolding structures are often used to build stages, seating, and lighting rigs for concerts, festivals, and other large events.

Demolition: Providing a safe working platform for workers to dismantle structures systematically and safely.

In essence, wherever work needs to be performed at height, and a stable, safe, and robust working platform is required, scaffolding steps in as an indispensable solution. It stands as a testament to engineering ingenuity focused on making challenging tasks achievable and, most importantly, safe.

FAQ

Is scaffolding safe?

Yes, when properly erected, inspected, and used. Scaffolding is designed to provide a safe working platform. However, it can become dangerous if safety protocols are ignored, such as improper assembly, overloading, or lack of regular inspections. Adhering to safety standards and regulations is paramount.

How often should scaffolding be inspected?

Scaffolding should be inspected by a competent person before each work shift and after any event that could affect its integrity, such as high winds, heavy rain, or any structural alterations. Initial inspection after erection and subsequent weekly inspections are also standard requirements in many regions.

Read More

What ls Scaffolding in Education and How ls lt Applied? —— Grand Canyon University

What is a Scaffolding? Components and Parts —— YouTube