H Frame Scaffolding Load Capacity: Safety, Standards, and Best Practices

Dec 09, 2025H frame scaffolding (Section/ Masonry Frame scaffolding) is a necessary and common construction scaffolding, providing the required workload, access, and mobility necessary for a variety of construction projects from residential to commercial, through to major public infrastructure.

The only thing that is non-negotiable for a construction site to be safe is the scaffolding. The structural integrity of any construction project is based solely on the Scaffolding's Load Capacity.

The calculation of the H frame scaffolding Load Capacity can be seen as a legal and moral obligation. If it is overlooked, it will result in the complete structural failure, serious injury, or death. Therefore, this detailed guide, created for Construction Managers, Engineers, and Equipment Rental Companies, details the standards, parameters, and best practices for utilizing H Frame Scaffolding safely.

Prior to analyzing a structure's load capabilities, it is essential to create a standard terminology system. A major contributor to extreme overloading of a structure occurs from a misunderstanding of these terms.

Working Load (WL), or Permissible Load – The Maximum load (Human, Material, Tools) that the scaffolding was designed and approved to safely support during daily use, is generally derived from dividing the Ultimate Load by the Safety Factor.

Rated Load – Refers to a classification of capacity from the manufacturer/design standard. Classifications for rated loads are common in the U.S. and worldwide, and are very often related to the weight distributed per square foot/metre:

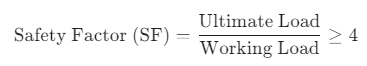

The establishment of safe scaffolding design is critical to ensure the structural integrity and performance of the scaffolding system. Safety Factor (SF) is the basis for this determination and is defined by both federal (OSHA) and state regulations. SF should ensure that when completing a particular task using scaffolding, the scaffold must be able to safely support at a minimum, its own weight plus four times the maximum intended load.

The 4:1 ratio also creates a safety tolerance for materials used, small variations in setting up the scaffold, and load dynamics. This means the Working Loads for scaffolding will always represent no more than 25% of the scaffold's final rated capacity (Ultimate Load).

The actual load capacity of an erected H-frame scaffold is a complex variable, influenced by several interdependent factors far beyond the initial manufacturer's rating.

The core strength relies on the components themselves:

The way the scaffold is put together dictates its stability and capacity:

This is often the most overlooked factor in load-related failures.

Cross Bracing and Diagonal Bracing: These components transform the individual frames into a rigid, monolithic structure. They prevent the frames from racking (shearing sideways) under vertical load or lateral wind force. A scaffold without proper, continuous diagonal bracing has a critically compromised load capacity.

Tie-ins to the Structure: For scaffolds exceeding a certain height (often four times the base width), they must be securely tied to the permanent building structure. Tie-ins prevent lateral sway and buckling, transferring horizontal wind loads and contributing to overall stability, which is essential for maximizing vertical load capacity.

A scaffold is only as stable as the ground it stands on.

Sill Plates and Base Plates: Every leg must rest on a base plate to distribute the vertical load. If the ground is soft, the base plate must sit atop substantial sills (mud sills or sole plates—typically timber) to spread the load over a wider area, reducing ground pressure to an acceptable limit.

Soil Bearing Capacity: The soil's ability to resist the scaffold leg's pressure must be assessed. If the soil compresses unevenly, it causes differential settlement, which creates eccentric loading and internal stresses, dramatically reducing the scaffold's safe working load.

Construction managers must systematically estimate the total load before use:

Dead Load: The weight of the scaffold components themselves (provided by the manufacturer/supplier).

Live Load (The Load to be Supported):

Environmental Loads: Primarily wind loads. High winds can generate enormous lateral (horizontal) forces, which, if not resisted by adequate bracing and tie-ins, can cause racking and failure, even if the vertical load is light.

Never rely on guesswork. If the total estimated load approaches the manufacturer's medium-duty rating, consult with a certified scaffold engineer to verify the design and actual capacity for your specific configuration.

The safe deployment of H-frame scaffolding hinges on a thorough, professional understanding of its load capacity. It is a commitment that extends from the initial engineering design and the quality of the rented equipment to the daily inspections by site supervisors. By adhering to the 4:1 safety factor, meticulously checking bracing and foundations, and maintaining strict load management protocols, construction companies and rental suppliers can ensure their platforms remain safe, compliant, and structurally sound. Safety is not a feature; it is the foundation upon which every successful construction project must be built.

What is the main cause of load-related scaffold collapse?

Can I temporarily exceed the Working Load limit?