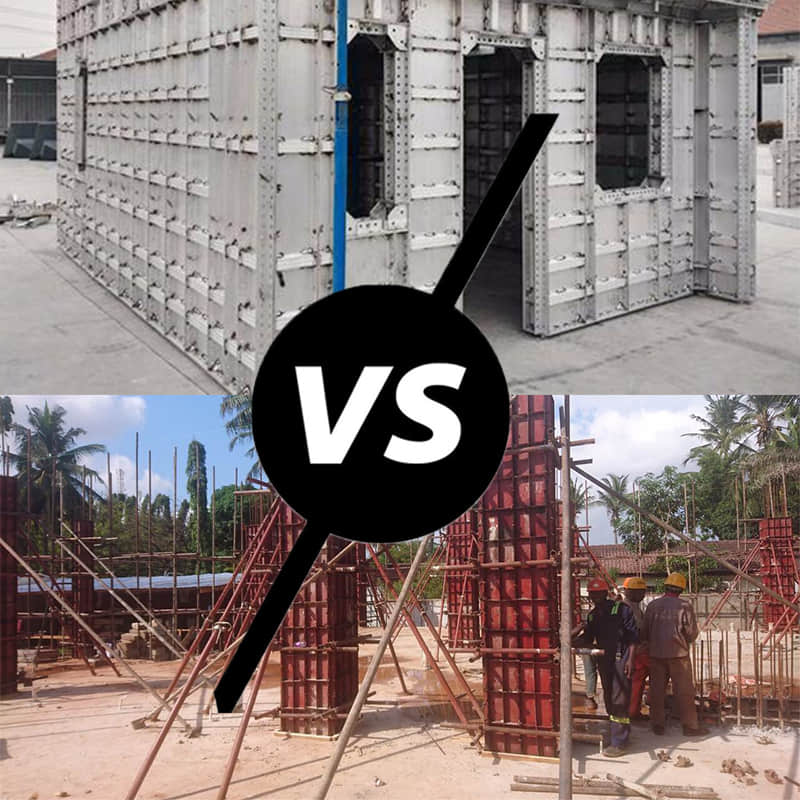

Aluminum Vs. Steel Formwork a Comprehensive Guide

Jul 29, 2025

The structure and finish of every building are derived from the formwork system - the temporary mold that concrete gets put into. A formwork system should be considered the first entire modular unit, which fundamentally affects the accuracy, detail, and quality of the final building. In modern construction, there are typically two systems that can be used: aluminum formwork and steel formwork. Each has its pros and cons to consider throughout the decision-making process of which system will best suit the contracting firm, developer, project managers, engineers, and construction crews concerns and needs. As this is a business decision, cost analysis and critical comparison of the systems throughout the processes lead to the decision process of which system will work best. The comparison information in this article will assist in your decision-making based on your project information, needs, and goals.

Understanding Steel Formwork: The Traditional Workhorse

For many years, steel formwork has been a staple of many construction sites due to its strength & durability. Steel formwork is a product that comprises a number of heavy-duty molds and forms made with steel plates & sections that are designed for high value and withstand large concrete pressures and a substantial amount of reuse.

Characteristics: Steel formwork is heavy and strong, and generally has to be moved with equipment like cranes to put it in place and move the steel forms from the site back to warehouses to reuse. Steel formwork material is heavy, durable, and strong and is applicable to demanding use.

Advantages:

Incredible durability and load capacity: Steel formwork can handle heavy pours of concrete and complicated structural forms, making it great for large infrastructure projects. Steel frame formwork can hold a large amount of weight during pouring.

Durability: Steel formwork systems are built to last, and when they are taken care of properly, they can be used for many years, which allows for good long-term investment returns.

High reuse factor: Even though steel form may be built for particular projects and may be custom-designed, steel can still be reused many different times, assuming the obligations of the project are similar.

Fabrication Flexibility: Steel can be fabricated, cut, welded, and changed to create complicated or curved shapes of concrete.

Disadvantages:

Heavy and Laborious: The heavy nature of steel forms requires cranes, and a large, typically skilled workforce to erect and disassemble, which takes more time during cycle times.

High Labor Costs: Involving handwork and the manipulation of labor, assemblies are labor-intensive.

Limited Availability of Standardization: Steel formwork is commonly a custom product. This is problematic for the design lead time and fabrication lead time, and costs for specials.

Maintenance: Steel is prone to rust, and care must be taken for regular power washing, clean up, and anti-corrosion treatments to extend its life.

Exploring Aluminum Formwork: The Modern Solution

Aluminum formwork is a game-changer in construction technology and is extremely popular due to its efficiency and quality of results in construction, especially with residential and high-rise building construction.

Features: Aluminum formwork systems are usually manufactured from high-strength alloys of aluminum and are extremely lightweight while being strong enough. They are generally modular and standardized with good assembly time.

Advantages:

Faster Build Seasons: Because aluminum modular components don’t weigh as much, they can be set and dismounted very quickly, and efficiencies, which condense timelines for your projects, leading to faster project delivery and redeployment.

Lower Labor Costs: Aluminum forms are so much lighter than steel that you can often handle the installation with fewer crew, and therefore have a smaller crew size, plus relying much less on heavy lifting equipment and skilled labor.

Better Surface Finish: Typical Aluminum surfaces are very smooth, which results in good,fair-faced concrete surfaces and often requires 0 little or no plastering costs to finish.

Reusability: Aluminum panel formwork systems are built for huge reuse, often 250-300 pours or more, with a little TLC. We have recently seen a system operating over 1,000 pours.

Standardization / Consistency: The interlock system with modular panels provides consistent dimensions, leading to enough measuring errors in identical repetitive structures, and enough to produce high quality.

Environmental Benefit: Aluminum is an extremely recyclable product, and its use will often lead to a reduction of landfill waste from products produced on site and much more sustainable building practices.

Disadvantages:

Higher Upfront Cost: An aluminum formwork system often has a higher initial cost than steel. Part of that is offset by labor savings, improved schedules, etc.

Less Versatile for Unique Shapes: Aluminum formwork is remarkable for repeated structures; however for highly unique or non-value add projects, its ability to create custom shapes is limited when compared to the custom fabrication of steel.

Although aluminum forms are resilient, if they are mishandled, they will dent. Dents may not affect the structural dimensions but may affect the finish of the concrete, etc.

Comparative Analysis: Key Decision-Making Factors

Choosing between aluminum and steel formwork involves a careful assessment of several critical factors. The table below provides a concise comparison:

Feature / Factor

Steel Formwork

Aluminum Formwork

Material Weight

Heavy

Lightweight

Strength & Load

Very High; ideal for heavy structures

High; excellent strength-to-weight ratio

Initial Cost

Generally Lower (per unit)

Generally Higher

Erection/Dismantling

Slower; often requires mechanical lifting

Faster; often manual handling possible

Labor Requirements

More laborers; often more skilled labor; crane dependent

Fewer laborers; less skilled labor; less crane dependent

Surface Finish

Good; may require more post-pour finishing

Superior; often fair-faced concrete, less plastering

Reusability

Good (e.g., 50-100 pours, project-dependent)

Very High (e.g., 250-300+ pours)

Versatility

High; excellent for custom, complex, curved shapes

Moderate; best for repetitive, standardized structures

Project Suitability

Heavy civil, bridges, dams, highly custom projects

High-rise residential/commercial, repetitive structures

Maintenance

Susceptible to rust; requires regular treatment

Less prone to rust; requires careful handling to prevent dents

Environmental Impact

Less recyclable; heavier carbon footprint from transport

Highly recyclable; lighter footprint from transport

Project Timeline

Longer cycles, slower project completion

Shorter cycles, faster project completion

Choosing the Right Formwork:

There is no universally "better" formwork system; the optimal choice is always project-specific.

Choose Steel Formwork When:

Your project will have highly customized, non-repetitive, or uniquely shaped concrete structures (e.g., artistic facade, complex bridge components).

You are doing heavy civil work like tunnels, large-span bridges, and dams, where strength is most important.

The budget for formwork is restricted at the front end, and overall project schedule and crew efficiency are the secondary concerns.

Choose Aluminum Formwork When:

You're constructing high-rise residential or commercial buildings with repetitive floor plans and structural elements.

Your project demands rapid construction cycles and adherence to tight deadlines.

Achieving a high-quality, smooth concrete surface that minimizes subsequent finishing work is a priority.

You are looking for long-term cost savings through reduced labor, faster project completion, and high reusability across multiple similar projects.

Sustainability and reduced on-site waste are important project goals.

Conclusion

The decision between aluminum formwork and steel formwork is a strategic one that directly impacts a project's cost, timeline, quality, and efficiency. As construction professionals, carefully evaluating the scale, complexity, budget, desired finish, and timeline of your specific project is crucial. By conducting a thorough cost-benefit analysis and understanding the distinct advantages of each system, you can make an informed choice that maximizes efficiency, enhances quality, and ultimately contributes to the profitability and success of your construction endeavors.

FAQ

What labor is needed?

Steel requires more skilled labor and heavy machinery. Aluminum is lighter, requiring fewer and less skilled laborers.

What about the concrete finish?

Aluminum generally produces a smoother, higher-quality finish, often reducing post-pour work.

Read More

Aluminum —— Wikipedia

Aluminum Formwork —— YouTube