The Definitive Guide to Cuplock Scaffolding: Boosting Safety, Speed, and ROI

Nov 10, 2025

One of the most popular and recognizable modular scaffold systems in the world is Cuplock Scaffolding. In addition to being an efficient and versatile heavy-duty support system, Cuplock Scaffolding is built for speedy erection and dismantling and is unique because of its efficient and unique cup-locking system. Fully developed by SGB in 1974, this system has established a worldwide standard for safety and efficiency in buildings, and represents a totally versatile system which excels in difficult high-rise or complicated places where traditional tubular scaffold (tubular and coupler scaffoldings) might prove to be less economical.

The most important feature of the Cuplock system is the connection of the nodal point. At intervals, normally 500mm, on the vertical standard are fixed bottom cups, and sliding on them are cups. Up to four horizontal members (ledgers or transoms) can be simultaneously locked into this nodal point by one blow with a hammer. Locking thus forms a rigid and secure connection, and each connection is at right angles to the one below.

What Are The Benefits of Cuplock Scaffolding?

For the construction industry, the selection of scaffolding directly reflects on the time in which projects can be completed, safety records, and ultimately profits. The advantages of Cuplock mean there is a better return on investment (ROI) on the capital employed for both users and renters.

Quick Assembly (Speed and Labor Savings):

The simple and positive locking method of Cuplock enables the system to be erected and dismantled in less time than conventional methods. This means speed of completion and considerable savings in labour costs.

Versatility (Flexibility In Complex Situations):

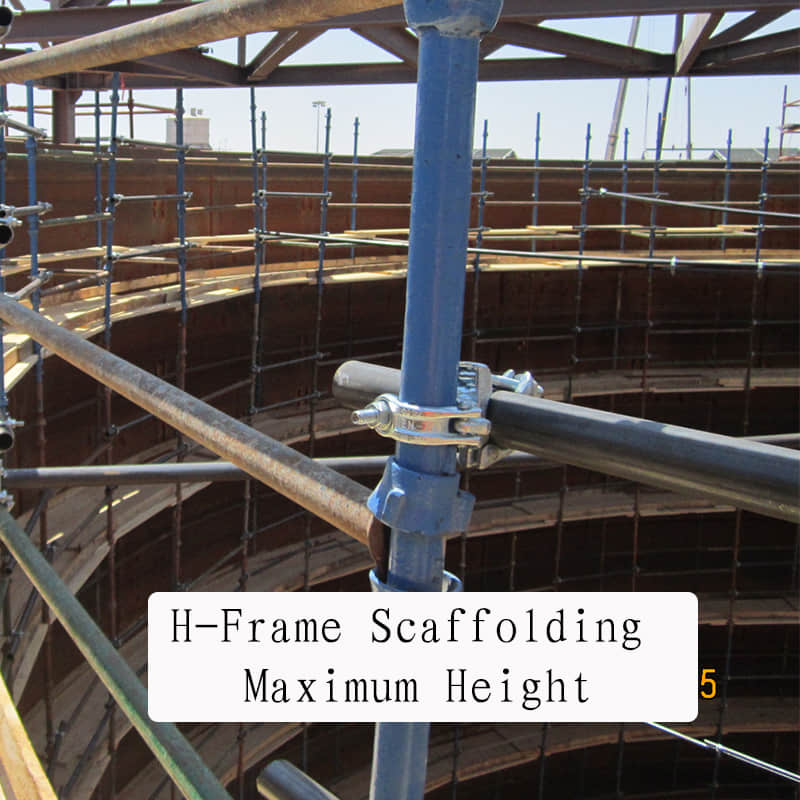

The Cuplock System, having a capability to connect up to four components at one node, possesses a remarkable adaptability to all kinds of structures, straight, curved, and circular, as well as complex facade work and internal structures.

Durability (long service life and low replacement costs):

The components are usually made from high-quality galvanized steel, which makes them very resistant to corrosion and wear and tear in use. This long service life is a big plus for the rental companies when they require a durable and saleable stock.

Low Maintenance (lower operating costs):

The system has no loose fittings, wedges, or bolts (like Ringlock or tube and coupler), which are apt to get lost on the job. This simplicity does away with the necessity of frequently replacing missing parts and speeds up the checking of stock.

Accessibility (Ergonomic Design):

The uniform grid structure ensures that workers have safe and easy access, and materials can be easily transported across working platforms.

Safety (Engineered Reliability):

The positive locks make for a rigid, slip-resistant connection and conform to world standards of safety. The system is designed for excellent load-bearing capacity that renders it safer for heavy-duty service.

Cost-Effective (Maximizing Rental ROI):

Although initial investment may be higher than a simple scaffold, its speed of erection, low maintenance, and long life mean an overall better long-term ROI, for both users (faster projects) and owners (greater viability of rental cycles).

What Are The Uses of Cuplock Scaffolding?

Cuplock Scaffolding finds extensive application in the following fields due to its high strength and versatility:

General Building: For access scaffolding and work platforms on residential, commercial, and industrial jobs.

Shoring (formwork) Support: Because of its great load-carrying abilities, it is eminently satisfactory for supporting heavy concrete formwork beams and slabs.

Infrastructure Projects: Greatly employed in bridge, highway, or tunnel construction.

Maintenance & Restoration: Very useful for scaffolding structures with more complexity, like oil refineries, power plants, and historical buildings.

Marine & Offshore: Its galvanized finish makes it suitable for severe and corrosive marine environments.

What Materials Are Used in Cuplock Scaffolding?

The main material for all significant bearing items is high-strength, structural steel.

Material: Usually, either Grade S235 or S355 steel (in accordance with European standards) or high-strength equivalent steel.

Finish: The parts are normally hot-dip galvanized (HDG). This process produces a thick coating of zinc, which is greatly superior to a paint coating as far as prevention of rust is concerned for the durability and life of the system, especially in harsh climates.

What Are The Components Of A Cuplock Scaffolding System?

The Cuplock System is modular, consisting of a limited number of standard items which fit together:

Cuplock Standards (Verticals):

These are the vertical load-bearing members which have the characteristic Cuplock nodal points, the fixed lower cup and the movable upper cup, welded at regular intervals (e.g., 500mm or 1000mm) and transferring the vertical load to the base.

Ledgers (Horizontals):

These horizontal members connect the standards, providing structural stability and forming the frame for the working platforms. They have end blades that slot into the nodal cups.

Intermediate Transoms:

These are placed between the ledgers to support the scaffold boards or decks. They also have end blades that are secured by the cup mechanism.

Cantilever Frames:

Specialized components are used to create working platforms that project outwards from the main scaffold structure, often necessary for gaining access to difficult-to-reach areas of a facade.

Base Plates & Jacks:

They provide a stable base for the standards and enable adjustment to the height required when the ground is uneven.

U-Heads:

It is used at the top of the standards for the support of bearers, beams, or primary formwork structure in shoring work.

What is a Cuplock System?

The cup-lock scaffolding system is a complete and robust support and access system. Its principal feature is its method of connection, that is, the cup-lock connection. This connection makes it possible to obtain a great rigidity of the structure: the ends of the beams and the cross-beams are introduced into the cup-shaped fixing apparatus below, and by means of a knock with the hammer, the four parts are anchored firmly in their places.

What is the Cuplock Scaffolding System Size?

Cuplock scaffolding is standardized, but when we say "size," we mean, for the most part, the dimensions of the components and the resulting bay sizes:

Bay Widths (Transom Lengths): Common widths are 0.9m, 1.2m, 1.5m, and 1.8m.

Bay Lengths (Ledger Lengths): Common lengths range from 1.2m, 1.8m, 2.5m, to 3.0m.

Standard (Vertical) Spacing: The distance between cup connections is typically 500mm (0.5m) or 1000mm (1.0m), allowing for fine control over platform height.

Tube Diameter: The outside diameter of the steel tubes is generally 48.3mm, which is standard across most scaffold systems globally, ensuring compatibility with standard fittings (like couplers).

How to calculate the amount of Cuplock scaffolding?

Accurate calculation is crucial for cost control and site safety. The following is a simplified overview; a qualified scaffolding engineer must always perform final calculations.

Steps for Basic Quantity Estimation:

1. Define Dimensions: Determine the required length (L), height (H), and width (W) of the scaffold structure.

2. Standards (Verticals) Calculation:

Number of Bays (Length): L / (Bay Length)

Total Standards: ≈ (Number of Bays + 1) * 2 (for two lines) * (Height / Standard Spacing)

3. Ledgers (Horizontals - Lengthwise) Calculation:

Total Ledgers: Number of Bays * (Height / Platform Lift Height) * 2

4. Transoms (Horizontals - Width-wise) Calculation:

Total Transoms: (Number of Bays + 1) * (Height / Platform Lift Height)

Pro Tip for Rental Companies: Accurate calculation minimizes overstocking or under-supply, which is key to maximizing fleet utilization and achieving the highest rental margins. Always factor in extra components for bracing, ties, and specialized access points (like stair towers).

FAQ

What makes Cuplock faster than traditional scaffolding?

Its unique cup-locking mechanism allows up to four horizontal components to be secured into the vertical standard with a single hammer blow, eliminating the time spent on numerous loose couplers and bolts.

What is the primary advantage of Cuplock over Ringlock?

Cuplock offers simplicity and extreme speed for straightforward, repetitive layouts (like building facades) and is highly efficient for heavy-duty shoring due to its robust, right-angled connections.

What is the load capacity of Cuplock?

Cuplock is a heavy-duty system. A single standard can typically support a vertical load of 2 to 3 tons (20-30 KN), depending on configuration and bracing. Always consult the manufacturer's specifications.