The Definitive Guide to Concrete Formwork Removal: Timing, Technique, and Tools

Sep 19, 2025Concrete casting isn’t as simple as pouring concrete and calling it a day. Once the pour is completed, that’s only half of the job. What many don’t realize is that removing the formwork is the final and most important step. Formwork removal, or stripping, is the final step of the process, and it can be serious business. Removal of formwork is all about timing and a precise approach. If done right, this is where the structural integrity of your freshly finished concrete begins. If done wrong—say, with haste—it can create expensive mishaps, safety hazards, and unusable final concrete.

In this guide, we will take you through how to do both safely and effectively by discussing the mechanics of the formwork removal timeline and providing a step-by-step guide on how to remove concrete forms safely and how to strip concrete forms.

When it comes to removing concrete forms, the number one rule is patience. Wait until the concrete has gained enough compressive strength to support itself without the forms. Removing forms before the concrete is adequately cured can lead to crumbled, sagging, and cracked concrete, while waiting too long can cause the forms to bond to the concrete and be more difficult to remove, and can even damage the surface.

Concrete Strength: The concrete strength, not just the "dryness," is what matters. Concrete strengthens over time due to hydration. It may feel strong after one day, but only a small percentage of its final strength has developed.

Structural Purpose: Different elements of a structure require different curing durations before you can take forms away.

Vertical Forms (Walls, Columns): These forms are generally non-load-bearing and are simply functional for holding the concrete in place. They should be released, typically, within 24 to 48 hours after the pour, past a point where the concrete is strong enough to retain its shape.

Horizontal Forms (Slabs, Beams, Arches): These are load-bearing and need to hold the weight of the concrete itself, which will require much longer waiting times until the strength of the concrete has developed enough to eliminate deflection or failure.

· Slabs: On average, forms can be stripped after 3-4 days, but the prop and some shoring will stay in place until the slab reaches the design strength (typically 7-14 days, or longer).

· Beams and Arches, and Soffits: These support considerable loads, and 14-21 days or longer may be required before final form and prop removals. Always check with the structural engineer or the specifications.

Environmental Considerations: Ambient temperature and humidity have a serious impact on curing. Curing is significantly retarded in cold temperatures, but extending the wait period would have to be longer. Conversely, high temperatures accelerate curing; however, adequate curing is still paramount for successful results.

For large-scale or critical projects, engineers use tools like maturity meters or test cylinders to accurately determine the concrete's strength, eliminating guesswork and ensuring a safe and precise removal time.

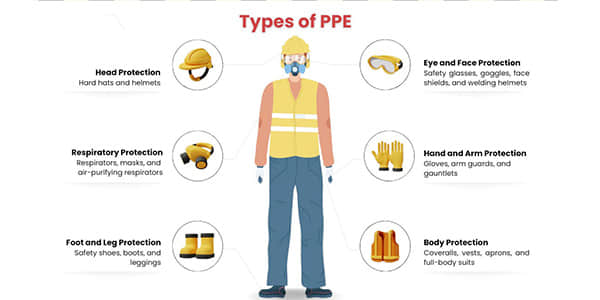

Before demolding, first be sure you are wearing the appropriate personal protective equipment (PPE).

The right equipment makes the job safer and more effective:

Working systematically, start at one end of the formwork. Use your hammer and pry bar to gently loosen the form boards. Never use brute force. A light tap with the hammer on the side of the board can help break the bond between the form and the concrete. Slowly and carefully pry the boards away from the concrete surface.

If you are using reusable forms (such as steel or plastic), they often have specific release mechanisms. Follow the manufacturer's instructions for a clean and efficient strip.

Once each form board or panel has been removed, immediately clean it. Use a stiff brush or scraper to remove all concrete residue. This is essential for adding to the lives of your forms. If you are going to reuse your forms, apply a form release agent on any form before storing it. This method will lighten your load significantly when you are stripping the pour.

A form release agent is a chemical applied to the formwork before pouring concrete. It creates a barrier that prevents the concrete from bonding with the form surface. This not only makes stripping faster and easier but also ensures a smooth, blemish-free concrete surface and allows you to reuse your formwork.

The final appearance and durability of any concrete structure are heavily influenced by the care taken during formwork removal. By respecting the concrete's curing process, using the right tools, and following a patient, methodical approach, you can achieve a flawless finish every time. This attention to detail saves time, reduces waste, and ultimately contributes to a safer, more professional project.

Do you have any questions about specific types of formwork or concrete mix designs? Or would you like to explore different kinds of formwork systems for your next project?

What is a form release agent, and why is it important?