The Definitive Guide to Calculating Formwork Quantity

Sep 17, 2025

Accuracy is critical in the construction industry. While we put in the physical effort as builders into the final product of a concrete structure, it is the formwork that is the very action that makes a foundation form. It is exact and, almost always, invisible. Ask any professional, even a seasoned construction professional who has built concrete structures for many years, and I can assure you they will say it is easy to discount the impact, along with the actual quantities of formwork in construction. The ramifications of making a mistake are pretend. There are real-life results – project slowdowns, budget overruns, possible personal injuries, lawsuits, loss of tools, etc. The list could go on. And the ramifications of "it was just a mistake" can ruin lives! The implications can go even further than that, as proper calculations can place you as a project manager, civil engineer, or material supplier ahead of the competition in the marketplace.

So, this is not going to be a simple addition of numbers based on a "formula" for formwork quantity. This discussion is far more complex, and I will include throughout this guide discussions on safety, project planning, and estimating the quantity of concrete to pour on the project as equally important topics as the total formwork quantity. You will be glad you took the time to learn and understand these principles.

The fundamental law of formwork calculations is calculating the surface area of the concrete to be in contact with the formwork. The area of the concrete will typically be measured in square meters (m2). The area for each separate structural element must be calculated for the total quantity, which is added together. You also want to add on a factor of waste, which is typically between 5% and 10%. The waste accounts for damages to the material, cutting loss, and overlaps.

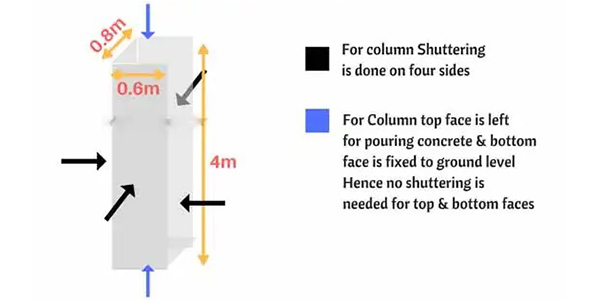

Regarding Columns: All four vertical edges require formwork.

Formula: Formwork Area = (Perimeter of the base of the column) × (Height of the column)

Example: For a rectangular-shaped column that is 0.5m x 0.6m and 3.0m tall, the perimeter is 2×(0.5m + 0.6m) = 2.2m.

Thus, the formwork area is: 2.2m × 3.0m = 6.6m².

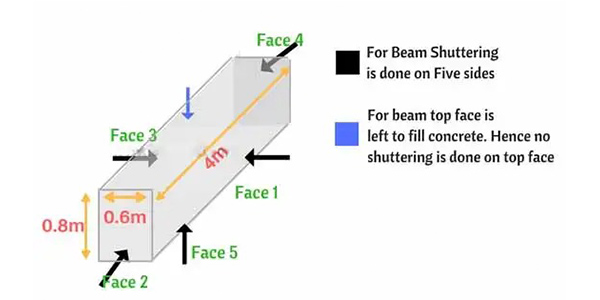

Beam: Formwork is needed on the two vertical sides and the base.

Formwork Area = [(2 × height) + width] × (length of beam)

Example: For a beam of 0.4m wide, 0.6m high, and of length 4.0m, the formwork area = [(2 × .6m) + 0.4m] × 4.0m = [(1.2m + 0.4m) × 4.0m] = [1.6m × 4.0m] = 6.4m².

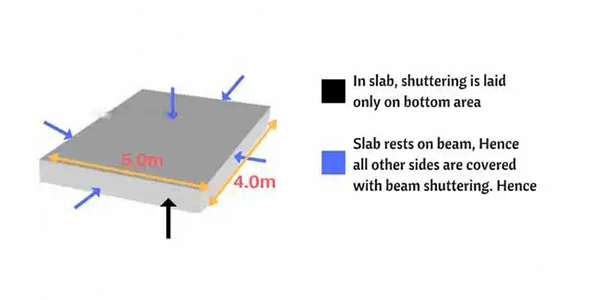

Slabs: Calculation includes both the soffit (bottom) and the edges.

- The area for soffit formwork (bottom surface) is Length x width.

- The area for edge formwork (perimeter of slab) is (perimeter of slab) × (thickness of slab).

Example: If the slab is 12m long, 8m wide, and 0.2m thick, the soffit area is calculated as: 12m×8m = 96m².

The perimeter is 2×(12m+8m) = 40m. The edge formwork area is calculated as: 40m×0.2m = 8.0m².

For Walls: Formwork is generally needed on both sides of the wall.

Formula: Area of Formwork = 2 x (Length x Height)

Example: If the wall is 10m long by 2.5m high, the formwork area is 2 x (10m x 2.5m) = 2 x 25m² = 50m².

An accurate calculation is just the beginning. True expertise lies in integrating this data into a comprehensive project plan that accounts for safety, scheduling, and budget.

Formwork failure is a leading cause of construction accidents. Prioritizing safety through proper planning and execution is crucial.

Effective planning transforms your calculations into a smooth on-site operation.

Formwork costs can account for a substantial portion of a project's budget, often between 20% and 30% of the total concrete structure cost. A detailed breakdown is essential for accurate budgeting.

Becoming proficient at calculating formwork quantities is about more than just estimating - no, it's about developing a sustainable project plan. When you combine accurate measurements with a positive understanding of safety measures, utilization of advanced planning, and estimating costs, you have taken a step towards managing your projects with speed, safety, and profitability.

A well-executed formwork plan is the silent hero of a successful concrete structure, ensuring that the foundations you build are not just strong but also smart.

Ready to optimize your project management? Contact us today to learn how our expert solutions and innovative formwork systems can streamline your next construction project and maximize your return on investment.

1. What is the basic principle of formwork calculation?

2. How do you account for material wastage?

3. How does formwork reusability impact cost?

4. How do you calculate formwork for non-standard shapes?

5. When is it safe to remove formwork (stripping)?