In the dynamic world of construction, excavations for foundations, basements, or trenches demand meticulous safety planning. Shoring systems are paramount, serving as temporary or permanent supports to prevent soil collapse, protect adjacent structures, and ensure worker safety. Choosing the right system from the diverse options available is key for project success.

This guide explores 12 principal types of shoring systems, outlining their mechanisms, common applications, and key benefits, helping you navigate these critical construction choices.

Why is Shoring Crucial?

Shoring isn't just a recommendation; it's often a necessity:

- Worker Safety: Its primary role is protecting lives by preventing excavation cave-ins.

- Structural Protection: It safeguards nearby buildings, roads, and utilities from damage caused by ground movement.

- Project Efficiency: Shoring provides a stable environment, enabling construction to proceed without interruption.

- Regulatory Adherence: Safety regulations (like OSHA) mandate shoring for excavations beyond certain depths.

- Cost & Delay Prevention: A collapse can lead to severe project delays, budget overruns, and legal issues.

12 Key Shoring Systems Explained

Shoring methods vary by installation, materials, and purpose. Here's a look at 12 common systems:

1. H and I-Beam Shoring (Soldier Pile and Lagging)

- How it Works: Steel H or I-beams (soldier piles) are driven or drilled in at intervals. As excavation proceeds, lagging (timber, concrete panels, or steel plates) is inserted between them to retain soil.

- Applications: Deep excavations (basements, underground structures), suitable for cohesive soils.

- Pros: Cost-effective, flexible, relatively fast installation. Can be combined with tie-backs.

- Cons: Less suitable for very soft or water-laden soils without dewatering; timber lagging is temporary.

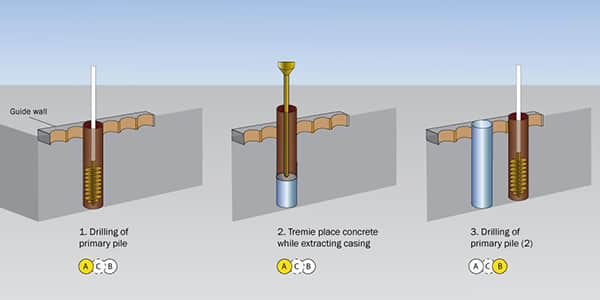

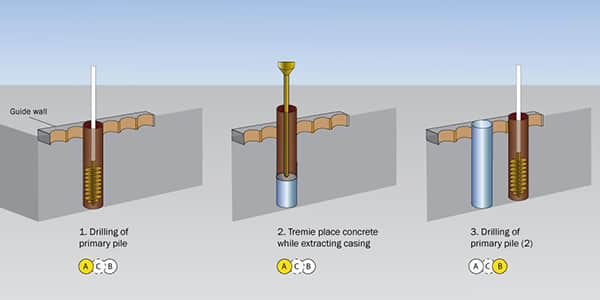

2. Secant Pile Shoring

- How it Works: Overlapping (intersecting) reinforced concrete piles create a continuous, watertight wall. Primary (female) piles are cast, then secondary (male) reinforced piles are drilled between them, cutting into the primary piles.

- Applications: Deep excavations in urban or water-sensitive areas, retaining walls, shafts.

- Pros: Forms a very stiff, watertight barrier, minimizes ground movement, can be a permanent structure.

- Cons: More expensive and slower to install, requires specialized equipment.

3. Contiguous Pile Shoring (Tangent Pile Shoring)

- How it Works: Concrete piles are installed side-by-side with small gaps (tangential), not overlapping.

- Applications: Excavation support where groundwater isn't a major issue; retaining walls in cohesive soils.

- Pros: More economical and faster than secant piles.

- Cons: Not watertight due to gaps; less stiff than secant walls.

4. Sheet Piles

- How it Works: Interlocking sheets (steel, vinyl, or concrete) are driven or vibrated into the ground to form a continuous wall.

- Applications: Waterfront structures (cofferdams, seawalls), excavations in soft/water-logged soils, temporary or permanent retaining walls.

- Pros: Good water resistance (especially steel), high strength, reusable materials.

- Cons: Installation can cause noise/vibration; difficult in dense/rocky soil.

5. Diaphragm Walls (Slurry Walls)

- How it Works: Deep, reinforced concrete walls are built in excavated trench panels. Bentonite slurry supports the trench during excavation, then a steel cage is inserted, and concrete is poured from the bottom, displacing the slurry.

- Applications: Very deep excavations, permanent basement walls, tunnels, and cutoff walls, especially in urban areas.

- Pros: Extremely strong, stiff, and watertight; can be part of the permanent structure; minimal noise/vibration.

- Cons: High cost, specialized equipment and expertise needed, slower process.

6. Raking Shoring

- How it Works: Inclined members (rakers) of timber or steel brace an unstable wall. Rakers bear against a wall plate and transfer load to the ground via a sole plate.

- Applications: Supporting unstable walls due to settlement, adjacent excavation, or damage.

- Pros: Simple to erect, adaptable to various wall heights.

- Cons: Can obstruct ground access; requires firm ground for raker bases.

7. Hydraulic Shoring

- How it Works: Hydraulic pistons in prefabricated aluminum or steel units exert pressure against trench walls.

- Applications: Primarily temporary trench shoring for utilities and small excavations.

- Pros: Quick to install/remove (often from outside the trench), lightweight, reusable.

- Cons: Suited for limited trench depths/widths; requires hydraulic pumps and pressure monitoring.

8. Soil Nail Shoring

- How it Works: Steel bars (nails) are grouted into holes drilled into a soil face. This reinforces the soil mass, which is often then covered with a shotcrete facing.

- Applications: Stabilizing slopes, supporting excavations (often top-down), and repairing retaining structures.

- Pros: Cost-effective, flexible for irregular shapes, less disruptive (noise/vibration).

- Cons: Not for very low shear strength soils or high groundwater without extra measures; needs experienced contractors.

9. Timber Shoring

- How it Works: Uses timber components (planks, posts, struts, walers) to support excavations or structures. Designs vary from simple trench boxes to complex structural supports.

- Applications: Shallow trenches, supporting floors/roofs during alterations, lagging in soldier pile systems.

- Pros: Lightweight, easy to modify on-site, cost-effective for small, temporary jobs.

- Cons: Susceptible to rot/pests, limited strength compared to steel/concrete, labor-intensive for large setups.

10. Dead Shoring

- How it Works: Vertical posts or props provide direct support to elements like roofs, floors, or beams. Load distribution is managed by head and sole plates.

- Applications: Supporting structures during alterations (e.g., wall removal) or fresh concrete until it cures.

- Pros: Direct and effective vertical support; components often reusable.

- Cons: Can obstruct work area; requires careful load calculation and stable foundation.

11. Flying Shoring

- How it Works: Horizontal struts (timber/steel) span between two parallel walls, providing support when the intermediate structure or ground is removed. Supported by wall plates and often includes needles and cleats.

- Applications: Supporting walls during demolition of an adjacent building or across an excavation.

- Pros: Keeps the ground space clear between walls.

- Cons: Requires stable, parallel walls; span is limited by strut strength.

12. Pneumatic Shoring

- How it Works: Similar to hydraulic shoring but uses compressed air to extend struts that support trench walls.

- Applications: Temporary trench support, particularly where lightweight and rapid deployment are needed.

- Pros: Lightweight, easy to handle, quick installation.

- Cons: Requires an air compressor; potential for sudden pressure loss.

Choosing the Right Shoring System: Key Factors

Selecting the optimal shoring system involves considering multiple project-specific variables:

- Soil Conditions: A geotechnical report detailing soil type, strength, and groundwater level is paramount.

- Excavation Depth & Geometry: Deeper, larger excavations demand more robust systems.

- Site Constraints: Space, accessibility, proximity to structures, and vibration/noise limits are crucial.

- Supported Structure: The nature of what's being supported (open cut, existing building) dictates the approach.

- Anticipated Loads: Earth pressure, water pressure, and surcharge loads must be calculated.

- Project Duration & Permanence: Is the shoring temporary or part of the final structure?

- Cost & Budget: Balance safety and functionality with overall project costs.

- Environmental & Regulatory Factors: Compliance with all safety and environmental standards is non-negotiable.

- Water Table: High groundwater may require watertight systems or dewatering.

- Equipment & Expertise: Some systems need specialized equipment and experienced installers.

Conclusion

Shoring systems are fundamental to safe and successful construction involving excavations. Each of the 12 types discussed offers distinct capabilities suited to different challenges, from the deep-earth stability of diaphragm walls to the versatile utility of timber or hydraulic shoring.

A comprehensive understanding of these options, guided by thorough site investigation and engineering expertise, allows for the selection of the most appropriate system. By prioritizing safety and sound engineering, construction projects can confidently build on a stable and secure foundation. Always engage qualified geotechnical and structural engineers for the design and approval of your shoring system.

FAQ

Can shoring systems be permanent?

- Yes, some shoring systems can be designed to be incorporated into the permanent structure. For example, diaphragm walls and secant pile walls often serve as permanent basement walls. Soil nail shoring can also be a permanent stabilization solution.

What are the most common shoring types for deep excavations?

- For deep excavations, common and robust systems include H-beam and lagging (soldier piles), secant pile walls, contiguous pile walls, and diaphragm walls. The specific choice depends on the factors listed above, especially soil conditions and water presence.

How does groundwater affect shoring selection?

- Groundwater significantly influences shoring selection. High water tables or permeable soils may necessitate watertight systems like secant pile walls, diaphragm walls, or steel sheet piling with sealed interlocks. Dewatering systems may also be required in conjunction with the shoring.

Read More

Shielding Vs. shoring —— escglobalgroup

Excavation Shoring Systems —— deepexcavation