The Definitive Guide to Calculating Formwork Quantity

Sep 17, 2025

Introduction

Accuracy is critical in the construction industry. While we put in the physical effort as builders into the final product of a concrete structure, it is the formwork that is the very action that makes a foundation form. It is exact and, almost always, invisible. Ask any professional, even a seasoned construction professional who has built concrete structures for many years, and I can assure you they will say it is easy to discount the impact, along with the actual quantities of formwork in construction. The ramifications of making a mistake are pretend. There are real-life results – project slowdowns, budget overruns, possible personal injuries, lawsuits, loss of tools, etc. The list could go on. And the ramifications of "it was just a mistake" can ruin lives! The implications can go even further than that, as proper calculations can place you as a project manager, civil engineer, or material supplier ahead of the competition in the marketplace.

So, this is not going to be a simple addition of numbers based on a "formula" for formwork quantity. This discussion is far more complex, and I will include throughout this guide discussions on safety, project planning, and estimating the quantity of concrete to pour on the project as equally important topics as the total formwork quantity. You will be glad you took the time to learn and understand these principles.

Part 1: Basic Rules for Formwork Calculation

The fundamental law of formwork calculations is calculating the surface area of the concrete to be in contact with the formwork. The area of the concrete will typically be measured in square meters (m2). The area for each separate structural element must be calculated for the total quantity, which is added together. You also want to add on a factor of waste, which is typically between 5% and 10%. The waste accounts for damages to the material, cutting loss, and overlaps.

Basic Formulas for Common Structural Elements

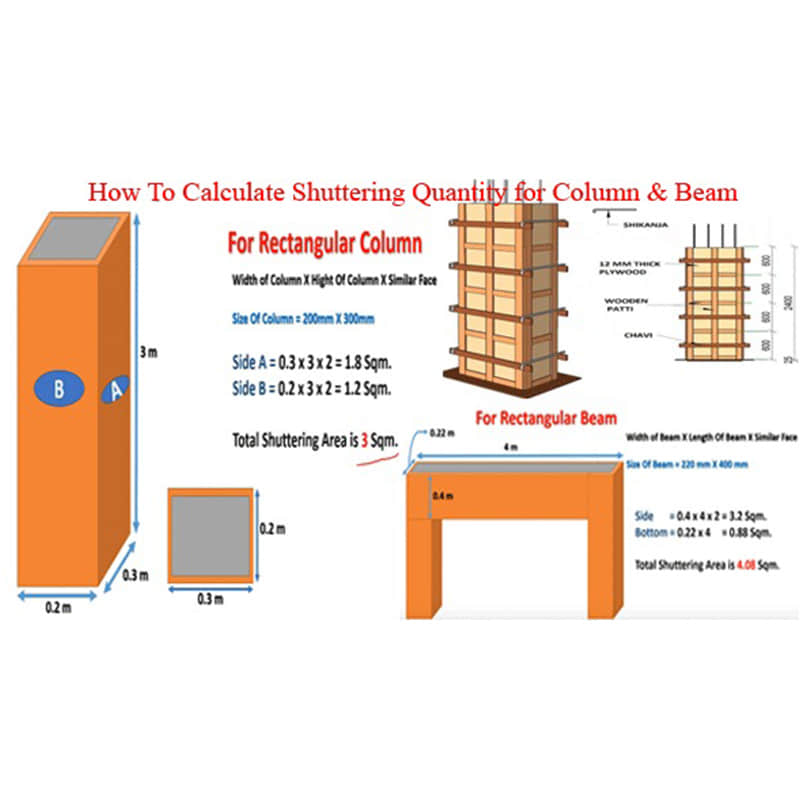

Regarding Columns: All four vertical edges require formwork.

Formula: Formwork Area = (Perimeter of the base of the column) × (Height of the column)

Example: For a rectangular-shaped column that is 0.5m x 0.6m and 3.0m tall, the perimeter is 2×(0.5m + 0.6m) = 2.2m.

Thus, the formwork area is: 2.2m × 3.0m = 6.6m².

Beam: Formwork is needed on the two vertical sides and the base.

Formwork Area = [(2 × height) + width] × (length of beam)

Example: For a beam of 0.4m wide, 0.6m high, and of length 4.0m, the formwork area = [(2 × .6m) + 0.4m] × 4.0m = [(1.2m + 0.4m) × 4.0m] = [1.6m × 4.0m] = 6.4m².

Slabs: Calculation includes both the soffit (bottom) and the edges.

- The area for soffit formwork (bottom surface) is Length x width.

- The area for edge formwork (perimeter of slab) is (perimeter of slab) × (thickness of slab).

Example: If the slab is 12m long, 8m wide, and 0.2m thick, the soffit area is calculated as: 12m×8m = 96m².

The perimeter is 2×(12m+8m) = 40m. The edge formwork area is calculated as: 40m×0.2m = 8.0m².

For Walls: Formwork is generally needed on both sides of the wall.

Formula: Area of Formwork = 2 x (Length x Height)

Example: If the wall is 10m long by 2.5m high, the formwork area is 2 x (10m x 2.5m) = 2 x 25m² = 50m².

Part 2: Safety, Planning, and Cost Estimation

An accurate calculation is just the beginning. True expertise lies in integrating this data into a comprehensive project plan that accounts for safety, scheduling, and budget.

A. Formwork Safety:

Formwork failure is a leading cause of construction accidents. Prioritizing safety through proper planning and execution is crucial.

Design and Engineering: A qualified engineer needs to take responsibility for the design of the entire formwork system, including the loads above, which include the weight of wet concrete, construction equipment, and the weight of workers. A pre-pour inspection is to be performed to verify that the formwork is braced, shored, and secured in order to perform its function.

Material and Component Inspection: All formwork panels, ties, braces, and props needed to be inspected for visible damage prior to using the formwork. Damaged materials should not be left on site.

Safe Stripping: Formwork should never be stripped until the concrete has gained adequate strength. The adequate strength is determined by concrete strength tests, not by observation. A stripping plan is also a very important means to ensure the concrete does not suddenly catastrophically fail.

B. Strategic Project Planning with Formwork

Effective planning transforms your calculations into a smooth on-site operation.

Choosing a Formwork System: Selecting the formwork system of your choice—wood, steel, aluminum, or plastic—is critical in this case. Steel and aluminum will be preferable if there is a lot of repetitively designed formwork due to greater durability and reuse. Wood shall work better in the design of trough-like custom shapes where construction is not repetitively designed. With each formwork system, there is a repetition factor regarding the number of times it can be expected to be used. The repetition factor greatly influences the long-term cost.

Scheduling: The scheduling of the industrial overall schedule shall simultaneously address the formwork schedule. The formwork schedule will have to be integrated into the scheduled concrete deliveries, rebar installations, and other trades, with emphasis on a constant and uninterrupted flow of work on the job site.

Anticipating and acting on risks: Plan on the unexpected during the job (weather delays, not enough of a required product delivered, etc.). Providing yourself a time buffer and a few feet of extra material should save on time and costs.

C. Comprehensive Cost Estimation

Formwork costs can account for a substantial portion of a project's budget, often between 20% and 30% of the total concrete structure cost. A detailed breakdown is essential for accurate budgeting.

Material Costs: This is the direct cost of the formwork panels, ties, and props, which is generally charged per square meter. Don't forget the costs of consumables such as nails, release agents, and screws.

Labor Costs: This tends to be the largest cost component. Labor is needed to assemble, erect, strip, and handle the materials. The more complex the design and the system, the more labor hours will be used.

Equipment and rental costs: You'll include costs to rent the formwork system itself and any lifting equipment (e.g., cranes) for moving the larger formwork panels.

Indirect costs: You will include costs for storage, costs for repair, and calculated material wastage.

Conclusion

Becoming proficient at calculating formwork quantities is about more than just estimating - no, it's about developing a sustainable project plan. When you combine accurate measurements with a positive understanding of safety measures, utilization of advanced planning, and estimating costs, you have taken a step towards managing your projects with speed, safety, and profitability.

A well-executed formwork plan is the silent hero of a successful concrete structure, ensuring that the foundations you build are not just strong but also smart.

Ready to optimize your project management? Contact us today to learn how our expert solutions and innovative formwork systems can streamline your next construction project and maximize your return on investment.

FAQ

1. What is the basic principle of formwork calculation?

The core principle is to calculate the surface area of the concrete that will be in contact with the formwork. This area is typically measured in square meters (m²).

2. How do you account for material wastage?

Always add a wastage factor of 5% to 10% to your total calculated area. This covers material lost from cutting, damage, and overlaps. For complex designs, a higher percentage may be necessary.

3. How does formwork reusability impact cost?

Reusable systems (like steel or aluminum) have a higher upfront cost, but their ability to be used multiple times drastically reduces the cost per use over a large project, making them highly cost-effective in the long run.

4. How do you calculate formwork for non-standard shapes?

For curved or irregular structures, you need to use more advanced geometric formulas or break the shape into smaller, manageable sections. Modern BIM (Building Information Modeling) software can perform these calculations automatically, offering high accuracy.

5. When is it safe to remove formwork (stripping)?

Formwork should never be removed before the concrete has gained sufficient strength to support its own weight and any superimposed loads. The required strength is determined by a structural engineer and verified through on-site concrete testing.