What Is Frame Scaffolding - An Essential Guide

Oct 17, 2025

In the world of construction, providing safe and efficient access to elevated work areas is a fundamental requirement for project success. While there are dozens of different systems of scaffolding available, one type has been basic to the construction industry because of its simplicity of application, adaptability, and reliability—this is frame scaffolding. Sometimes called sectional scaffolding, this type of scaffold is used at the same time on small residential jobs as well as on large public works projects.

This Manual is intended for those in the construction industry who are called upon to supply proper access. Whether you are a project manager, a contractor who provides a rental fleet, a distributor of building materials, or a purchasing officer for public works, this paper will provide useful information regarding frame scaffolding. It will include a discussion of the various components of frame scaffolding, its applications, its types, and the important safety standards that govern its use.

The Core Concept of Frame Scaffolding

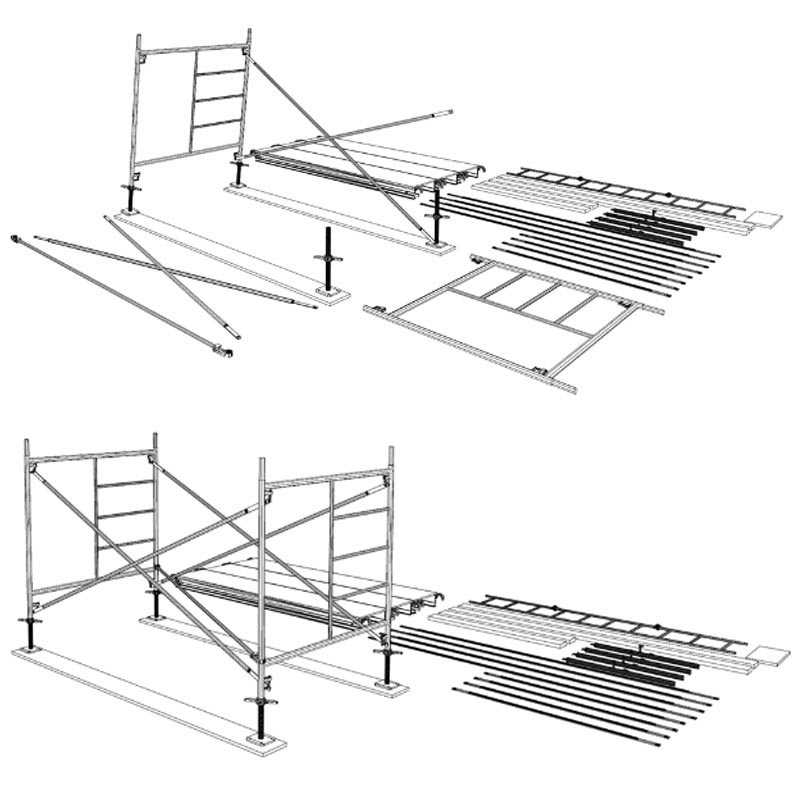

Frame scaffolding is fundamentally a modular scheme composed of fabricated frames that are locked together by cross-bracing. Its principle is simple: to design a strong, reproducible structural unit which can be stacked vertically and easily extended horizontally. The frames are made of high-tensile steel, which is laced together by cross-bracing in an X pattern to give extraordinary lateral stability.

This simple but effective plan permits of rapid erection and dismantling, making it an ideal choice for projects where time and labor costs are critical factors.

Key Components & Accessories

Understanding each part of a frame scaffolding system is vital for ensuring a safe and functional assembly.

Key Components

Vertical Frames: The principal load-bearing components. The common styles are walk-through, mason, and ladder frames.

Cross Bracing: Tubular members that connect the vertical frames for rigidity and prevent any swaying.

Base Plates & Screw Jacks: Base plates spread the load over the ground. The screw jack (or leveling jack) permits adjustments for height on an imperfect terrane for a perfectly level working structure.

Coupling Pins: Used for securely stacking the frames vertically, coupling one frame on top of another.

Platforms & Planks (Decks): The working surface, usually of wood, aluminum, or steel, and OSHA-approved material.

Guardrails and Toeboards: The essential fall protection system, consisting of a top rail, mid rail, and a toeboard to prevent tools from falling.

Essential Accessories

Casters (Wheels): Locking, heavy-duty casters that transform a stationary scaffold into a mobile or rolling tower for tasks requiring frequent movement.

Outriggers: Widen the scaffold's base to increase stability, which is crucial for preventing tall towers from tipping.

Stair Units & Ladders: Provide safe and efficient vertical access, a significant safety upgrade from climbing the frames.

Hoisting Arms: A simple pulley system attached to the scaffold to safely lift light materials and tools.

Debris Nets & Enclosures: Used in public areas to contain dust and debris, protecting the surrounding environment and providing workers with weather protection.

Frame Scaffolding Applications

Frame scaffolding's value is demonstrated in its wide range of practical applications:

Facade Work, Painting, and Cladding: Its ability to create long, continuous platforms makes it perfect for painters, EIFS installers, and cladding specialists working on building exteriors.

Masonry and Bricklaying: Using mason frames provides an unobstructed area for bricklayers, and it is robust enough to support the heavy weight of workers and materials.

Public Works and General Maintenance: Government agencies and maintenance departments rely on it for routine work on public buildings, schools, and hospitals, such as window replacement and roof repairs.

Interior High-Ceiling Access: When built as a rolling tower, it is excellent for interior work in large spaces like auditoriums, gyms, and warehouses for accessing lighting, ceilings, and ductwork.

Stucco and Plastering: Conventionally, a stable platform is often a prerequisite for a plasterer to plaster a surface.

Types of Frame Scaffolding

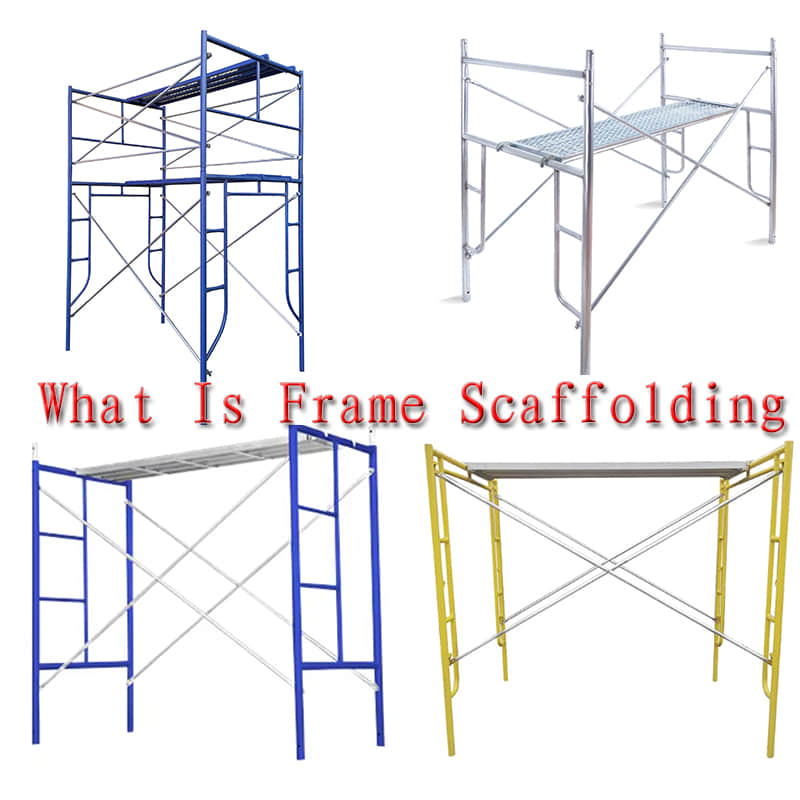

The choice of the correct style of frame is of the utmost importance in obtaining the maximum efficiency and safety.

Common Frame Styles

Walk-Through Frames: Provide an open portal, creating clear walkways for personnel and materials along the scaffold.

Mason (or Bridge) Frames: Designed with an open top, allowing masons to work on a wall without a horizontal bar obstructing them.

Ladder (or Narrow) Frames: Narrower sections, often with built-in ladder rungs, are perfect for use in confined areas like stairwells.

Brand Compatibility

It is important for rental companies and dealers to become aware of the fact that there exist different systems (for example, Safway-style, Waco-style, etc.). Generally speaking, we find that parts and materials from different brands are often not interchangeable. Indicating that brand compatibility is an important consideration, with a primary focus on safety.

Why Choose Frame Scaffolding? Key Advantages

The popularity of frame scaffolding rests on a special combination of advantages:

Efficiency and Speed: The modular structure allows for rapid erection and dismantling, directly contributing to decreased labour costs and keeping projects on schedule. This provides particular advantages to commercial contractors and government agencies.

Versatility: Suitable for the majority of common construction and maintenance applications, from brickwork to painting.

Economy: Frame scaffolding normally represents a lower first investment than more complex systems. Its durability and low maintenance ensure for rental companies and dealers strong returns-on-investment.

Transportability and Storage: The facility for neatly stacking frames and bundling braces facilitates logistics, an important advantage for the management of large inventories and mobilizing on a large scale.

Safety First

Compliance with OSHA requirements is mandatory. A scaffold is a safety device only if used properly.

Stable Base: Always set up scaffolds on a solid, level base, with mudsills on soft ground and screw jacks to level the scaffold. The height of the scaffold should not exceed four times its minimum base dimension unless it is tied to a building.

Fall Protection: OSHA requires guardrails to be used on any platform more than 10 feet above the level below. This includes a top rail, mid-rail, and toeboard.

Load Capacity: All parts must be able to support their own weight plus at least four times the maximum load for which they are designed. Bridges must have complete flooring.

Competent Person: A competent person must supervise the erection of scaffolds and must inspect them before each working shift to determine and correct hazard conditions.

Common Mistakes to Avoid

Errors can lead to catastrophic failures. Avoid these common pitfalls:

Unstable Foundations: Setting up on unlevel or soft ground without proper preparation.

Missing Components: Omitting cross braces, pins, or guardrails to save time.

Overloading: Exceeding the scaffold's intended load rating with workers or materials.

Improper Access: Climbing on cross braces instead of using a proper ladder or stair unit.

Neglecting Inspections: Failing to conduct daily inspections by a competent person.

Conclusion

Frame scaffolding has earned its place as an industry staple. For a wide array of construction and maintenance tasks, it offers an unparalleled blend of efficiency, versatility, and value. Its rapid assembly and proven reliability make it an intelligent choice for contractors focused on productivity, rental companies managing diverse fleets, and government agencies seeking dependable solutions.

When used in accordance with rigorous safety standards, frame scaffolding provides a secure platform that empowers workers to perform their jobs safely and effectively.

For expert advice on selecting the right frame scaffolding system for your project, or to inquire about our durable and compliant rental and sales options, contact our team of specialists today.