The Comprehensive Guide to Erecting Ringlock Scaffolding

Jul 15, 2023

Introduction

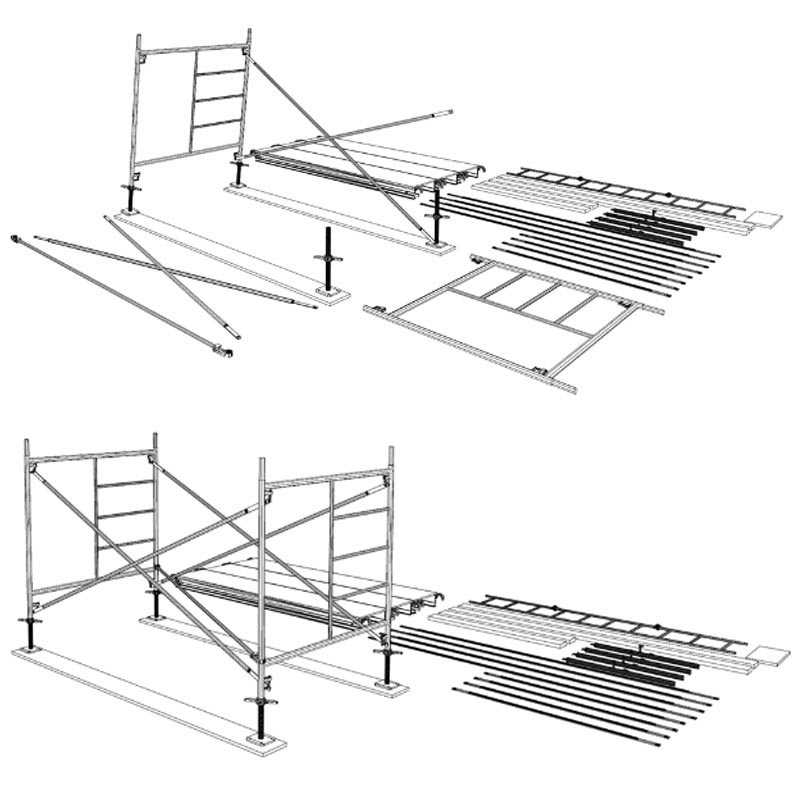

Welcome to our comprehensive guide on erecting ringlock scaffolding. In this article, we will provide you with a step-by-step process to help you successfully set up ringlock scaffolding for your construction projects. Ringlock scaffolding is a versatile and popular choice due to its durability, flexibility, and ease of assembly. By following our detailed instructions, you will be able to efficiently erect ringlock scaffolding while ensuring safety and stability.

Requirements For Ringlock Scaffolding Assembly

Before we delve into the assembly process, let's discuss the essential components and tools you'll need for erecting ringlock scaffolding:

Components:

Vertical Standards: These are the main vertical components that form the framework of the scaffold.

Ledgers: Horizontal components that connect the vertical standards, providing structural stability.

Diagonals: Diagonal braces that increase the rigidity of the scaffold structure.

Base Jacks: Adjustable components are used to level the scaffolding on uneven surfaces.

Steel Planks: Platforms where workers can stand and perform tasks.

Toe Boards: Placed along the edges of the scaffold to prevent tools or materials from falling.

Tools:

Hammer: For securing components in place.

Wrench: Used for tightening nuts and bolts.

Spirit Level: Ensures the scaffolding is level and plumb.

Tape Measure: For precise measurements.

Safety Equipment: Hard hat, safety harness, gloves, and non-slip footwear.

Now that we have the necessary components and tools, let's move on to the step-by-step process of erecting ring-lock scaffolding.

Step 1: Foundation Preparation

Clear the work area from any obstacles, debris, or potential hazards.

Ensure the ground is level and stable.

Place base plates or sole boards on the ground to provide a solid foundation.

Adjust the base jacks on each standard to level the scaffolding.

Step 2: Vertical Standard Assembly

Start by connecting the first vertical standard to the base jack.

Insert the spigot of the next standard into the lower cup of the first standard.

Rotate the standard until the spigot locks into place.

Step 3: Ledger and Diagonal Placement

Attach ledgers horizontally between the vertical standards, ensuring a secure fit.

Add diagonals diagonally between the ledgers to enhance stability.

Repeat this process for each level of the scaffolding.

Step 4: Platform Installation

Place steel planks across the ledgers, ensuring they are secured in position.

Ensure the planks are level and overlap properly to prevent tripping hazards.

Install toe-boards along the edges of the scaffolding platforms for added safety.

Step 5: Safety Measures

1. Prioritize safety by providing workers with appropriate personal protective equipment (PPE) such as hard hats, safety harnesses, gloves, and non-slip footwear.

2. Clearly mark the scaffolding area with warning signs to prevent unauthorized access.

3. Regularly inspect the scaffolding for any signs of damage or instability and address them immediately.

4. Train workers on proper scaffold usage, including safe climbing techniques and weight limitations.

Step 6: Final Checks

1. Before allowing workers onto the scaffolding, perform a thorough final check.

2. Ensure all components are securely in place, with no loose connections or missing parts.

3. Confirm that the scaffolding is level, plumb, and stable using a spirit level.

4. Double-check the integrity of the steel planks and toe boards for any signs of damage.

You can refer to our product construction video:

Conclusion

By following this comprehensive guide, you are now equipped with the knowledge to erect ringlock scaffolding for your construction projects effectively. Remember to prioritize safety throughout the assembly process and conduct regular inspections to maintain the stability and integrity of the scaffolding.

In addition to providing you with professional interlocking scaffolding tutorial files and videos, AJ Scaffolding also has professional technicians to provide you with professional guidance services. In addition to interlocking scaffolding, we also provide other building materials, such as scaffolding accessories, formwork and its accessories, etc., to provide you with a one-stop building materials procurement service.

If you have any questions about the construction of interlocking scaffolding, or want to purchase other building materials, please contact us!

FAQ

What Is The Difference Between Ring Lock And Cuplock Scaffolding?

Ring Lock scaffolding uses a wedge and disc system for connection, which is easy and quick to install and remove, and has high flexibility and stability.

Cuplock scaffolding uses a cup buckle system for connection, which is quick to install and has good overall stability, suitable for large-scale and repeated use projects.

What Size Is Ringlock Scaffolding?

Common sizes of Ringlock scaffolding include standard parts (0.5m to 3m), crossbars (0.5m to 3m) and diagonal braces (0.7m to 3m), which can be customized according to needs.

What Is The Safety Distance For Scaffolding?

The safe distance of scaffolding is usually at least 3 meters away from power lines, and a working range of 1.5 meters is maintained around the building.

Relevant Information

What Is Ringlock Technology In Scaffolding? --- QUORA

Experimental Studies Of Ringlock Scaffolding Joint --- RESEARCHGATE

Scaffolding Families -Best Method To Use? --- FORUMS