The Importance Of Safety Net Drop Tests And How To Conduct Them

Jul 08, 2024Safety nets are developed to prevent workers from falling and also to prevent construction materials and tools from falling, causing harm to the ground personnel and facilities. Fall tests are imperative to ensure that the safety net can play an important protective role at critical times. Testing a safety net is important because it simulates real conditions of falling and verifies the performance and reliability of the safety net, providing strong evidence and safety assurance for construction.

To ensure the quality and performance of safety nets, each country and region has formulated corresponding industry standards, which include the design, manufacture, testing, and use requirements of a safety net. The following highlights a few of the primary industry standards:

1. International standards

2. American standard

3. Chinese Standard

4. Additional standards

To ensure the safety net is reliable and effective in real use, a strict drop test must be carried out. Here is the specific operation steps and needed equipment for drop test of safety net.

Before the drop test, you need to do a few preparations, to ensure that the test goes smoothly and get real data.

To succeed in carrying out a safety net fall test, various specialized equipment and tools should be used to ensure the test is completed smoothly and the results are accurate, as illustrated below:

The detailed steps and description of processes on a safety net drop test are below:

After test is completed, you must also complete some follow-up work as follows:

In safety net fall tests, damping capacity and force measurement are essential indicators to evaluate the performance of the safety net, which refers to whether the safety net can provide enough protection. You can know whether there is sufficient protection by measuring the energy the safety net can absorb and the force it can withstand when you fall. Next will specifically introduce the energy absorption and force measurement content.

The absorption capacity of energy measures the absorbability of a safety net by measuring the energy that can be absorbed by the safety net when subjected to a fall, which reduces the impact on the dropping item and on the safety net itself. To measure the absorption capacity of energy, there are several steps to follow:

Select drop test object weight and height. Select the drop test object according to the standard requirements (such as a 50 kg sandbag or a piece of metal), then measure the selection of the drop height (generally more than 6 meters).

Calculate the energy potential. Prior to falling, the drop test object has a particular potential energy which can be calculated by the following: E= m × g × h

Where E is the potential energy, m is the weight of the test object, g is the acceleration of gravity (9.81 m/s^2 approximately) and h is the drop height.

Transmission of Kinetic Energy: When the object is falling during the testing process, its potential energy is transformed into kinetic energy. The safety net that is used must absorb the energy to stop the falling object from causing damage to people and objects below. Kinetic energy can be calculated by using the formula:

Among them, Ek is the kinetic energy and v is the velocity of the falling object.

Record energy absorption : Use force sensors and data loggers to record the energy absorbed by the safety net during the fall and analyze its energy absorption effect.

Force Measurement refers to the assessment of maximum impact force of safety net that takes place if a fall takes place, which helps to determine the useful or load resistance force of the safety net. The general steps involved in force measurement are:

Installation of force sensors: Installation of force sensors in strategic locations on safety net such as on ropes and connection points, for accurate measurements of changes in force, when the safety net is subjected to a fall.

Release of test object: Force sensor starts to record force at the time when the test object falls as it is falling, to record the force conditions in real time, specifically the maximum impact value of force.

Data recording and analysis: To record the data from the force sensor, the data logger is used to analyze the data to understand how much force is applied to the safety net during its fall. Generally, the requirement of safety net is to sustain the force of maximum impact force multiple times and not fail. Colleagues are required to comply with the industry, and requirements for the safety net without fail.

Data comparison: To test Wether for data, and compare the measured data with the requirements in the standards, innnn the industry to determine whether the performance of the safety net is qualified.

Performance evaluation: By using the data of energy absorption and force measurement, appraise on the overall performance of the safety net including energy absorption capacity, maximum impact force bearing capacity and durability.

Improvement suggestions: If the test reveals that the safety net does not reach the required performance, analysis of the reason is needed, and then we would have to provide the suggestion for the improvements like the change of material, optimization in design or to improvement the manufacture process.

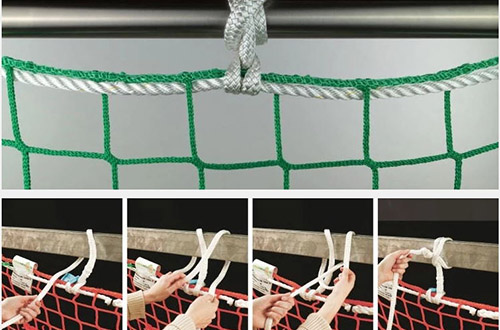

For the installation of the net, professionally trained personnel should be used who are knowledgeable about the correct procedures to follow for installation of the safety net, and in accordance with the manufacturers guide line, to ensure the safety net complies with the relevant regulations and standards during installation. Before starting the installation and following which, the installation area should be checked to identify potential impact hazards that could damage the safety net or compromise the function of the safety net. No gaps or spaces between the safety net and the structure should be left unattended that could lead to an object or person falling.

During the maintenance period regular checks should be undertaken to establish the safety net retains its integrity and the net is still capable of securing a fall event should it occur. Particular attention should be taken in adverse weather conditions or after heavy usage where damage or wear impairing the effectiveness of the safety net would need to be repaired or replaced to maintain the integrity and the integrity of the safety net for reliable long term safety.

Net ID is the most common representation of the safety net manufacturer, production batch and specific models of the safety net. Each safety net is usually given a unique number to track and manage its production and use. Grid size refers to the size of each mesh on the safety net and usually is measured in millimeters (mm) or inches (inches).

Different Grid Sizes Application Scenarios

Safety nets are normally used outdoors, so they are usually exposed to sunlight, which for a large number of materials with which they are manufactured have an negative effect on the material life of the safety net. Understanding the effects of UV degradation and taking appropriate preventive measures can also prolong the life of the safety net and guarantee that the safety of the safety net stays healthy.

Ultraviolet radiation can cause the following destructive effects on safety net materials:

In order to prevent and reduce the degradation caused by UV rays, here are some suggestions:

When safety nets are first used, they must be tested. The cost of testing is significant, but it is useful in preventing accidents and offsetting the costs of companies, both in lawsuits and settlements, including medical expenses and lost wages. In addition, work safety can be improved, legal and financial risks can be reduced, and personnel security can be improved.

The Essential Role Of The Worker In Safety Net Inspection:

Workers play an essential role in safety net inspection, with some duties falling beyond inspection, but still relevant to the safety net inspection, of the safety net:

Rope boundary testing, which involves checking the rope for fraying, cuts, kinks, or any damage that could render the net not viable.

Check for any impairments to the safety net, which may affect cutting, tears and / or punctures in the safety net that can reduce the functioning of the net.

Test the safety net limits by performing 'drop tests' by dropping a weighted bag to test that the net can withstand a falling worker.

Report an incident by making verbal reviews or reports in writing stating what has happened and do not use the safety net until it is fixed.

Safety net usage in construction around overhead construction to safeguard lives and properties from falling objects is an absolute necessity. The financial significance of implementing safety nets is significant. The installation will also require drop tests. Maintenance is essential prior to installation. Regular maintenance prevents the failure of a safety net. A drop test is necessary for the service life assessment for industrial safety standards.

How Often Should Safety Nets Be Drop Tested?

What Is The Standard For Safety Netting?

What Is The Lso Code For Safety Net?

Safety Net --- WIKIPEDIA

Safety Nets At Construction Sites --- ANSI

Which Safety Netting Type Is Right For Your Construction Site? --- INCORD