A Complete Guide to Types of Column Formwork

Jan 09, 2025

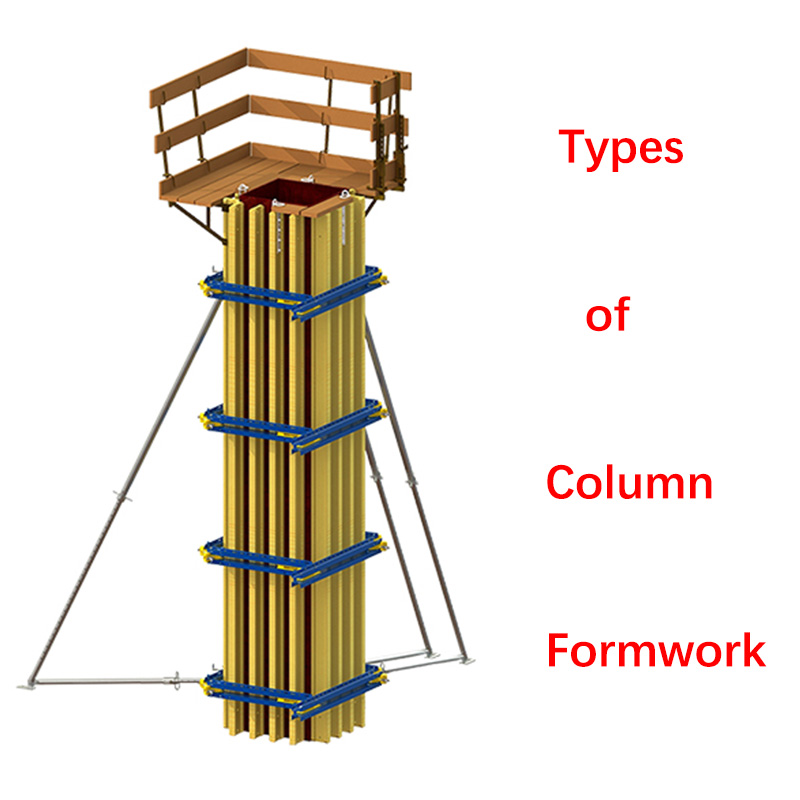

Types of Column Formwork

Column forms are designed to hold the shape temporarily and support the purpose until it is set and hardened at that state. Hence, selecting the proper column formwork type will greatly affect your project schedule and cost. This guide sets forth the key types of column formwork and features to help you choose the right template for your project.

Timber Column Formwork

Timber column formwork is one of the oldest and most versatile types of formwork used for concrete columns.

Materials: Wood or Plywood

Pros:

Easily customized to a variety of shapes and sizes

Affordable, ideal for small projects

Cons:

Poor dimensional stability

Poor durability, wood and plywood are susceptible to moisture, rain, and insect attack.

Best for: Temporary or short-term projects with custom or unique column shapes.

Steel Column Formwork

Steel column formwork with superior strength and durability, it’s ideal for large and repetitive projects.

Material: Prefabricated Steel Sheet

Advantages:

High reusability

Provides a smooth surface for concrete

Resists warping and moisture

Disadvantages:

Heavier and more expensive

Best suited for: Large buildings and high-rises

Aluminum Column Formwork

Aluminum column formwork combines durability with lightness for easy handling.

Material: Aluminum Sheet

Advantages:

Lightweight and easy to assemble

High reusability

Quicker construction time

Disadvantages:

Higher initial cost

Common projects: Projects that require fast construction and repeated use

Plastic and Fiberglass Column Formwork

Plastic and fiberglass column formwork systems are lightweight and corrosion resistant.

Material: Reinforced Plastic or Fiberglass

Advantages:

Lightweight and easy to transport

Good corrosion and weather resistance, not easily attacked by moisture, rust or insects

Easy to process and reusable

Disadvantages:

Limited durability compared to steel or aluminum

Best suited for: Small to medium-sized projects

Single-use Column Formwork

Designed for one-time use, Single-use column formwork is a cost-effective solution for simple projects.

Materials: Cardboard, plastic, a mixture of plastic and fiber reinforcements

Pros:

Low cost

Easy to disassemble and dispose of

Cons:

Not reusable

Best suited for: Low-budget, one-time use applications

Removable/Re-usable Column Formwork

The removable/re-usable column formwork system is designed for multiple uses, balancing cost-effectiveness and durability.

Material: Steel, Aluminum, or Plastic

Pros:

Cost-effective for multiple projects

Easy to disassemble and transport

Cons:

High initial investment cost

Common projects: Projects with repetitive construction elements

Modular Column Formwork

The modular column formwork system provides flexible configurations for different column sizes and shapes.

Material: Steel, Aluminum, or Plastic

Pros:

Versatile

Easy to assemble with standardized panels

Cons:

Requires initial setup and investment

Common projects: Projects requiring different column sizes

Specialized Column Formwork Solutions

Beyond the primary material types, several specialized solutions cater to particular column needs:

Adjustable Column Clamps: These metal clamps are used in conjunction with timber or plywood formwork to quickly adjust column dimensions and secure the panels.

Circular Column Formwork: Designed specifically for round columns, these can be made from steel, fiberglass, or even disposable cardboard tubes (Sonotubes™) for single-use applications.

Permanent Formwork: In some cases, the formwork is designed to remain in place after the concrete cures, becoming an integral part of the column. Examples include pre-fabricated concrete units or fiber-reinforced plastic (FRP) tubes that act as both formwork and a protective/decorative layer.

Formwork Demolding Cycles and Considerations

There are many de-molding cycles and considerations for the different types of formwork systems used at construction sites. In general terms, the molding cycle can be defined as the time used while striking formwork, ensuring neither affects concrete's strength and quality adversely. Different formwork types and types of structures to be built give rise to different time ranges.

Time of removal of column formwork: 24-48 hours.

Considerations:

Columns are vertical structures in which hydration takes place very rapidly up to strength. Given that the early closure of formwork occurs once the concrete has reached the specified strength, usually around 50%, the period within which the forms may be closed will generally be sooner.

Time of removal of slab formwork: general range of 7 to 14 days depending on span and load conditions.

Considerations:

For slabs, waiting periods should be concrete-grade-dependent and slab-thickness-dependent. The times for removal should, however, be done keeping in mind that any spans up to, and over, 4.5 meters are taken into account.

Time of removal of beam formwork: for side formwork, the interval is between 24-48 hours; for bottom formwork, 14-21 days.

Considerations:

The side forms of beams allow for quicker strikes, although the bottom formwork requires longer to stabilize the structure.

Wall formwork molding cycle: general range 24-48 hours.

Considerations:

Wall formwork can be stripped relatively early, thus correspondingly early than columns, once it attains adequate strength.

Demolding Considerations

Concrete tests must be carried out by measuring the compressive strength of the cast cubes.

Adhere to the specifications and rules of local code concerning the project.

Use modern forms that allow for quick release to enhance the efficiency of operations.

By fine-tuning the demolding cycle to meet site and structural conditions, the construction period can be optimized while assuring safe quality.

Choosing the Right Formwork: Key Considerations

With such a diverse range of options, making the right choice requires careful consideration of several factors:

Project Budget and Timeline: Timber might be cheaper upfront for small jobs, but reusable steel or aluminum can be more economical for large, repetitive projects.

Column Dimensions and Shape: Simple rectangular or circular columns are easier to form than complex, irregular shapes.

Required Surface Finish: Do you need a perfectly smooth, architectural finish, or will a standard finish suffice?

Labor Availability and Skill Level: Some formwork types require highly skilled labor for fabrication and assembly.

Site Accessibility and Equipment: The availability of cranes and other heavy machinery will influence the choice between heavy steel and lighter alternatives.

Environmental Impact and Sustainability Goals: Reusable formwork significantly reduces waste, aligning with greener construction practices.

Conclusion

In choosing column forms, due consideration must be given to the size, budget, and time of the project. Steel and aluminum forms are durable and reusable. Wood and disposable column shuttering are generally used for projects requiring short-term work. Modular and plastic forms promote ease, flexibility, and fast assembly. Nevertheless, careful consideration should be made in assessing a project to choose the form that achieves a proper mix of cost, efficiency, and quality.

FAQ

What is column formwork?

Column formwork refers to temporary structures, which can create the outline of the concrete columns during construction. These forms hold the wet concrete in place until it sets and hardens sufficiently. They can be made with several different materials, with each offering its unique advantages to different projects.

What are the different types of column formwork?

The various types of column formwork include:

Wood Column Forms: the traditional cheap, and easily adjustable.

Steel Column Forms: very strong and corrosion-resistant, and usually used for larger projects.

Aluminum Column Forms: light, reusable, corrosion-resistant, for various types of construction.

Plastic and Fiberglass Columns: the right choice for fast-paced finish jobs or mainly, for projects done on smooth finishes.

Disposable Column Forms: made of cardboard or any similar material and disposed of after use; comparable with small one-time projects.

Removable/Reusable Column Forms: Reusable numerous times, often made of aluminum or metal.

Modular Column Forms: Prefabricated to accommodate easy alterations for shape and size, suited for intricate and massive-scale projects.

Related Articles

What is Column Formwork? ——eiffeltrading