Construction steel quick-lock scaffolding is a lightweight, compact and versatile scaffold that can be erected in a short period of time.

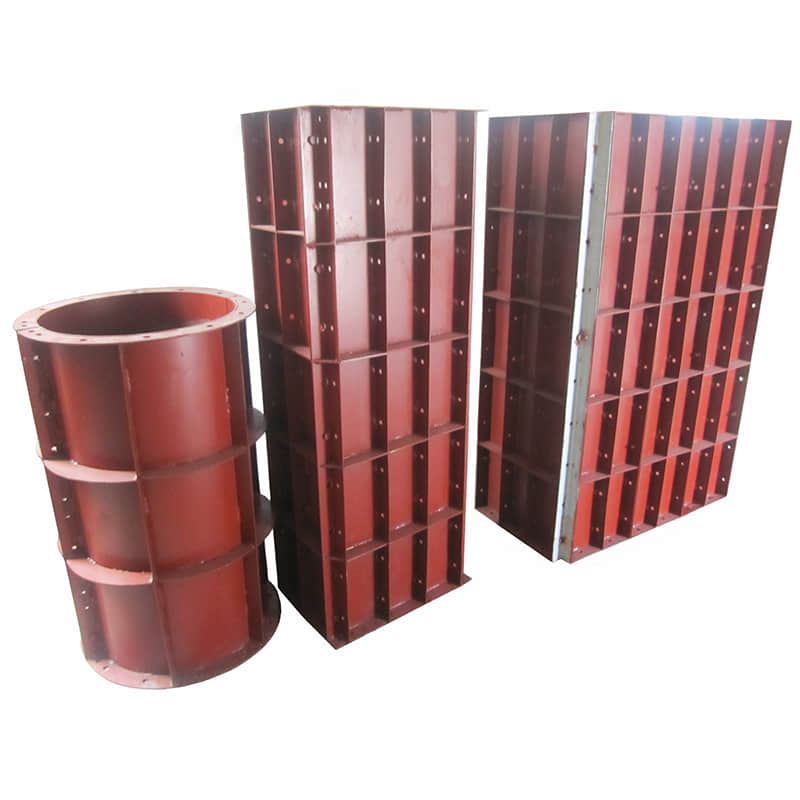

It can be used as load-bearing scaffolding and working scaffolding, providing support for access and supporting vertical loads. And it can be flexibly assembled into modular scaffolding, birdcage scaffolding, suspended scaffolding, mobile scaffolding and supported scaffolding. It is widely used in high-rise buildings, bridge, viaduct and highway construction, tunnel and church repair, and building renovation.

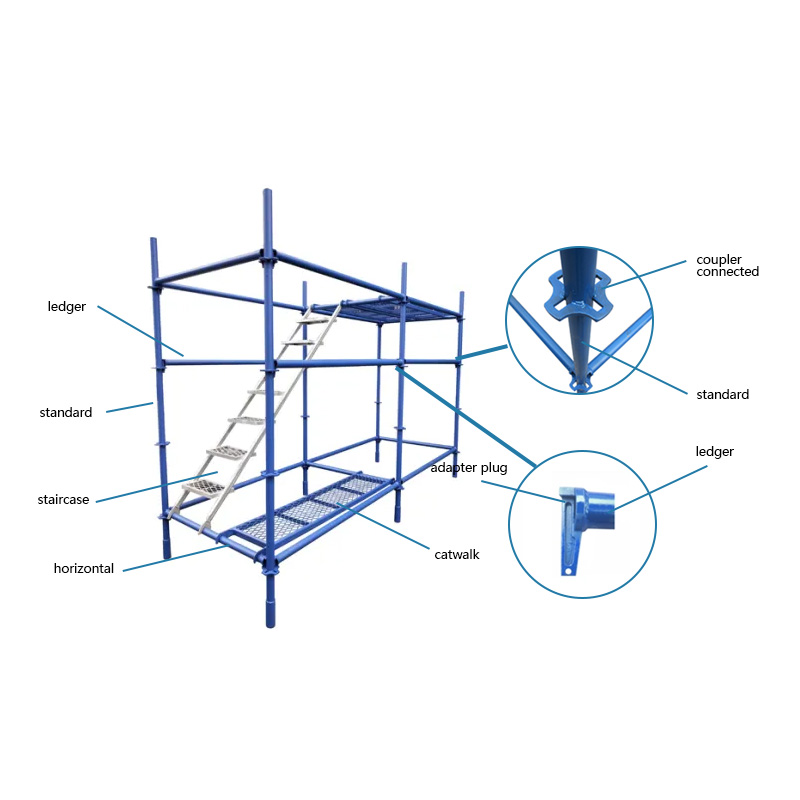

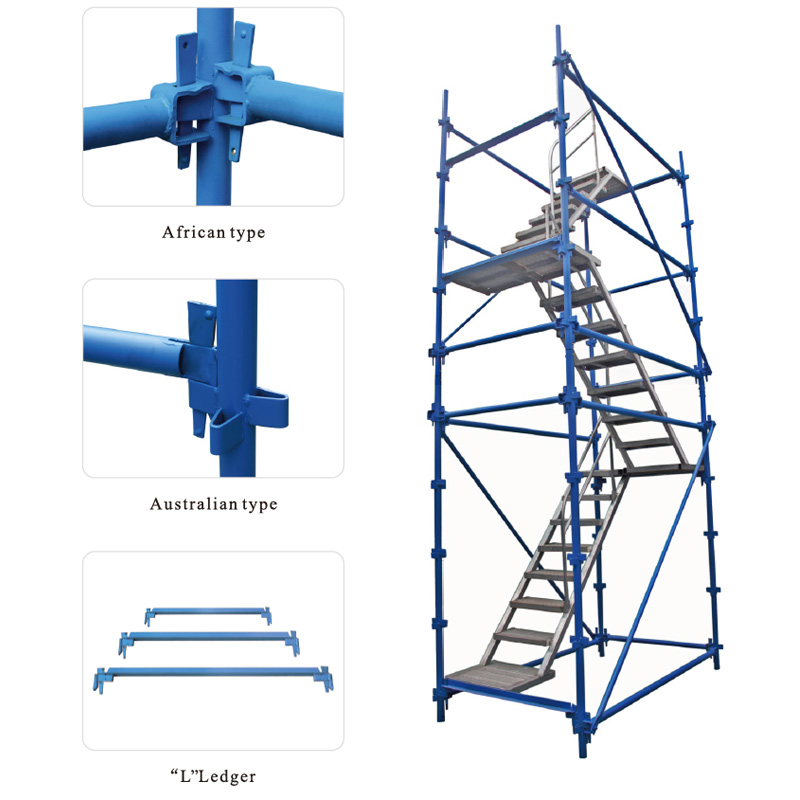

Quicklock Scaffolding System Components

3D Design Of Quick Lock Scaffolding

Under the umbrella of our factory, there is also a limited company. Our company can help you design a 3D model of a full range of quicklock scaffolding systems, allowing you to fully visualize the overall effect of the scaffolding when applied to your project!

Advantages Of Quicklock Scaffolding

Quicklock Scaffolding is linked with a wide array of benefits, for instance, time-saving installation, safe work and its proximity to the safety regulations and guidelines, flexibility, cost-effective price, and portable feature, compact design. These added qualities of quicklock scaffolding make it an ideal scaffolding for numerous construction and maintenance applications.

- Efficient Assembly: Quicklock scaffolding can be erected and dismantled faster than conventional scaffolding due to its simple

- Sturdy Construction: The design of Quicklock scaffolding provides enhanced stability and strength, supporting heavier loads and providing a safer working environment.

- Modular Design: The scaffolding system is highly adaptable, allowing for various configurations to suit different building structures and project needs.

- Compact Design: Components of Quicklock scaffolding are often lightweight and compact, making them easier to transport and store.

- Robust Construction: The design and materials used enhance the durability and reliability of the system, even in harsh environments.

- Flexible Access: The system allows for easy access to hard-to-reach areas, improving worker efficiency and safety.

Customized Quicklock Scaffolding For You

Having been a leading scaffolding manufacturer in China for many years, AJ Building can offer a range of custom surface treatments, dimensional specifications and additional accessories to suit any needs. This makes it a versatile solution to all kinds of construction and maintenance projects that you may have, and these advanced customization characteristics protect the safety of the scaffolding system and facilitate on-site productivity.

Surface Process:

Hot-Dip Galvanizing Process: The steel components are immersed in a bath of molten zinc until they are completely covered to create a protective layer

- Advantages: This process creates a thicker and more durable coating that will withstand harsh weather conditions and will last longer. The high quality galvanizing process is ideal for outdoor use and long-term projects.

Electro-Galvanizing Process: Zinc coating is applied to the steel components through an electrochemical process

- Advantages: The coating has a thinner zinc layer compared to hot-dip galvanizing but the finish is smooth with a nice appearance. The application of the coating is faster and cheaper, and the electro-galvanized scaffolding is commonly used in decorative applications and in cases that the scaffolding is placed in less corrosive environments.

Pre-Galvanizing Process: The steel components are coated with zinc before fabrication

- Advantages: The process applies a uniform protection at the length of the steel, protecting both ends and reducing pocketing, bridging and accumulation of zinc to the corners. It is a cost-effective solution, most suitable for any indoor or outdoor application where expansion is not needed.

Powder Coating Process: The scaffolding receives a dry powder coating that is applied on the surface then baked in high heat to form a solid bond

- Advantages: The powder-coating is an eco-friendly process and is available in many different colors. The coating is extremely durable protecting the surface from mechanical damages and provides a high resistance to chips and scratches as well as weather and rust. Due to the wide variety of colors available, the powder-coating is extensively used for both functional and decorative purposes.

Size:

- Custom Lengths and Widths: Components built to size to ensure a perfect fit for any building or system.

- Adjustable Heights: Heigh can be adjusted to reach any height and system requirements.

- Load-Bearing Capabilities: Adjust any scaffold to hold more items or distribute weight differently.

Metal Quicklock Scaffolding Project Experience

AJ building exports to more than 160 countries and regions and has rich project experience

High-Rise Buildings:

Ideal for constructing tall structures due to its stability, ease of assembly, and adaptability to various heights.

Residential Construction:

Used for building houses and low-rise buildings, providing safe and efficient access for workers.

Infrastructure Projects:

Applicable in the construction of bridges, highways, and tunnels, offering robust support and flexibility in complex environments.

Factories and Plants:

Used for maintenance, repair, and installation tasks in manufacturing plants, refineries, and power plants.

Stages and Platforms:

Used in the construction of stages, seating, and viewing platforms for concerts, festivals, and other large events.

Package

Each batch of your goods will be inspected by our professional quality inspectors before leaving the factory to ensure the quality of the goods. And use wooden pallets or iron pallets to protect the goods and prevent collision damage.

A Complete Guide To Quicklock Scaffolding

What Is Quicklock Scaffolding?

Quicklock scaffolding is a modular and innovative scaffolding system that is engineered for easy assembly and disassembly, with a simple and effective locking system ensuring that all the components are easily connected and separated. This construction scaffolding system is characterized by fast construction, which improves work efficiency, while at the same time avoiding the labor intensity and duration when assembling and disassembling the door.

Composition Of Quicklock Scaffolding

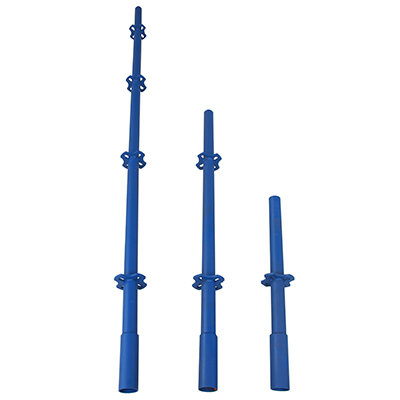

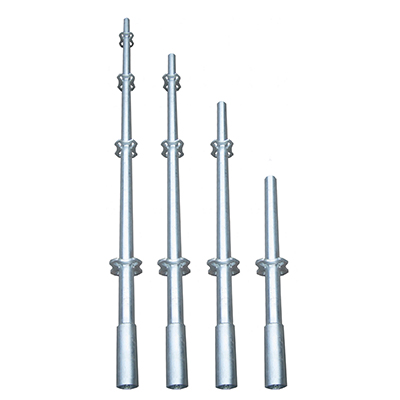

Standard: vertical support to form the main skeleton of the scaffold

Ledger: horizontal strip that connects the vertical support, adding stability to the entire construction

Diagonal pole: cross support piece, adding side support to the scaffold

Fasteners: a type of connecting hardware widely used in construction scaffolding to fix the vertical and horizontal bars

Working platform: Can be understood as a stage for construction workers to stand on

Safety accessories: Including safety net, handrail, etc. to ensure the safety of construction workers

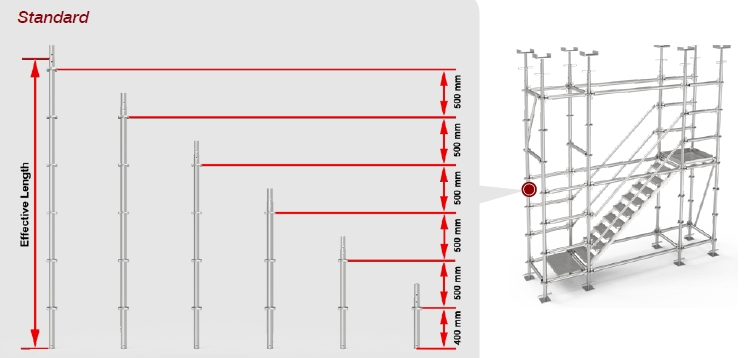

Standard Size Of Quicklock Scaffolding

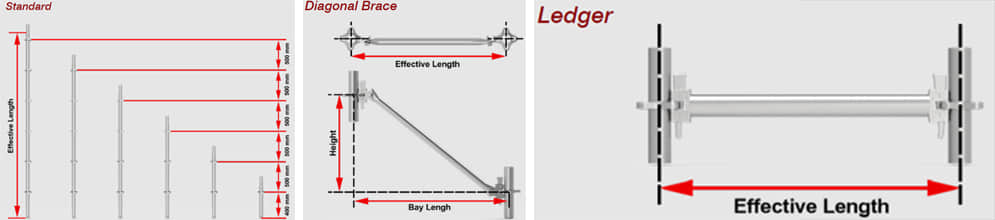

Standard:

2500*2.75/3.0/3.25*48mm

1900*2.75/3.0/3.25*48mm

1300*2.75/3.0/3.25*48mm

700*2.75/3.0/3.25*48mm

Ledger:

1770*2.75/3.0/3.25*48mm

1150*2.75/3.0/3.25*48mm

850*2.75/3.0/3.25*48mm

550*2.75/3.0/3.25*48mm

Diagonal Brace:

2.0m

2.5 m

3.0m

The Installation Steps Of The Quicklock Scaffold

Step 1: Installing the basics

You place the base plates on the ground and then install and adjust the adjusting feet to the correct height so that our scaffolding can be kept level.

Step 2: Installing the standard

It only needs a little labor force to be able to install the standard part to the appropriate position with the vertical adjustment foot. In addition, the verticality of the column verifies according to the level gauge.

Step 3: Installing the horizontal and diagonal Bearing bar

We can fix the cross bar to the locking device of the vertical pole, then set the diagonal bearing bar so that it can provide the lateral support of the structure to make our entire frame still stable.

Step 4: Installing the platform

Place the platform on the crossbar, and then use the locking devices again to lock the platform to the crossbar and the pole to no longer allow the scaffold to sway.

Step 5: Inspect and reinforce

Finally, we need to inspect and reinforce all the connection points and locking devices in the final scaffold.

Disassembly Steps Of Quicklock Scaffolding

Step 1. Preparation for disassembly

All tools and articles on the platform shall be removed and safety protection equipment shall be worn to ensure the safety of personnel when dismantling.

Step 2. Platform dismantling

One by one to release the lock clip of the platform, and the platform should be carefully removed to avoid collision with the other parts.

Step 3. Removal of horizontal and diagonal braces

One by one, the lock clip of the horizontal brace is released, then the screw jack or adjustable support is taken to ensure the horizontal support is not inclined. Carefully remove the oblique brace in order, and be careful to avoid impact with the body.

Step 4. Remove the standard

Loosen the connection between the column and the adjusting foot and remove the column from the adjusting foot to avoid collision and falling.

Step 5. Disassembly of the foundation

The foundation plate and leveling foot should be removed, and the ground construction should be handled to ensure that there is no residue.

How To Store Quicklock Scaffolding

1. Cleaning and Inspection

After the use, remove the dirt, dust, and oil and other foreign matter on the quicklock scaffolding, check each of the components is severely damaged, if damaged should not be used or should be replaced in time.

2. Separate and organize parts

Separate and organize the sections of the scaffolding, and mark each with its own separate parts for easy identification. This makes finding parts easier and reduces assembly time.

3. Choose the right storage location

It needs good storage, with a good dry place, away from the humidity. And do not direct sunlight. It is important to store these parts in a flat place so that the scaffolding does not fall and is damaged.

4. Storage method

Vertical Storage: The frames or other long components of the quicklock scaffolding can be stored vertically to save space.

The order of stacking: Place the heavier parts at the bottom of the stack and the lighter parts at the top so that the parts can be pressed and the metal parts are likely to be avoided.

Stacking height restrictions: Do not exceed the specified stacking height. When the stack is heavier, the weight of the stack is easy to fall.

5. Safety

Locking devices: A locking device is needed to prevent unauthorized use of the quicklock scaffolding when stored in a safe place.

Safety sign: A safety sign also needs to be placed in the storage area warning about the danger during storage of the quicklock scaffolding.

Why Choose AJ Building As Your Scaffolding Supplier

Our factory has more than 25 years of construction engineering experience, we can provide customers with the best products and services, based on its accumulated long-term experience, combined with the latest technology from the composite, designed to best meet the needs of the user.

Here are some of the advantages of our factory:

1. Ten thousand projects, rich experience and brilliant achievements: In the past 25 years, there have been tens of thousands of engineering projects, and this experience will benefit you all the time. We have always adhered to the policy of "quality and customer first".

2. By technological means, we can visually show you what your project looks like: We use 3D design technology to present your project before construction. Visualization eliminates the possibility of error in the product, so you can always have one in your mind.

3. Customized: All projects are unique. We can quickly provide customized solutions for quick lock scaffolding according to specific needs on request and provide expert guidance.

4. One-stop purchasing service: We are well aware that for customers who purchase many products, finding different suppliers is very time-consuming and energy-consuming. To meet customer needs, we can provide you with one-stop procurement services.

FAQ

Q: What is Quicklock Scaffolding?

A: Quicklock Scaffolding is a versatile and efficient scaffolding system used in construction and maintenance projects. It is known for its rapid assembly and disassembly.

Q: Is Quicklock Scaffolding safe to use?

A: Yes, when properly assembled and used according to safety guidelines and regulations, Quicklock Scaffolding is safe. It provides a stable and secure platform for workers and materials at different heights.

Q: Can Quicklock Scaffolding be used for both small and large-scale projects?

A :Yes, Quicklock Scaffolding is suitable for a wide range of projects, from small residential renovations to large industrial constructions.

en

en fr

fr es

es