Ringlock vs. Cuplock: A Comparative Analysis for Modern Scaffolding

Jul 23, 2025Scaffolding systems are a key part of contemporary construction and industrial engineering infrastructure, allowing work at height to be conducted safely and efficiently. Of all the modular scaffolding technologies available, Ringlock Scaffolding Systems and Cuplock system scaffolding systems are the two most popular and profitable systems and are best distinguished by their performance and versatility. However, no one's favorite system can be determined. Each system has many characteristics that are paramount in its design philosophy, structural performance, and suitable applications. The best choice will ultimately depend on the assessment of the project requirements, as it relates to the key project parameters: project complexity, load capacity, labour costs, and budget.

This document aims to identify and provide an exhaustive and thorough comparison and technical report on the Ringlock and Cuplock scaffolding systems with the intention of providing a helpful professional reference document for project managers and engineers and, those who are involved in making procurement decisions.

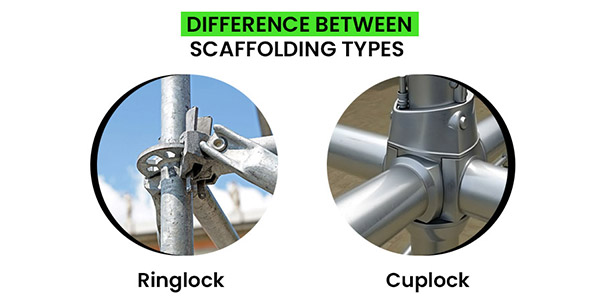

While they are both modular systems, the primary distinction between Ringlock and Cuplock is that both modular systems are defined by the locking systems at the node, and that difference defines the efficiency with which they are erected, the flexibility of structure, and the total effect of the systems.

As a long-established and mature technology, the name "Cuplock" intuitively describes its locking method.

· Main Construction: The vertical standards of the system have fixed lower cups welded at set intervals (spacing typically 500 mm). The ledgers and transoms have indicated blade ends (forged) that can be inserted directly into the lower cup. The upper cup is captive and can be released by dropping and rotating it. The inclined plane of the cup creates wedging action that will clamp all elements at the node and create a reliable four-way connection.

· Capacity Characteristics: Cuplock scaffolding is characterized by simple construction, fewer loose and incidental parts to the system, and intuitive operation. The scaffolding is very quick to erect and dismantle (faster than other methodologies), particularly when using it for larger-scale, regular building facades or structures. As a balanced, rapid methodology, Cuplock scaffolding continues to be used in general construction regularly over an extended period of time.

Ringlock is a more contemporary system, engineered to handle complex geometries and high load-bearing requirements.

· Core Structure: The system's standards feature a multi-port circular disk, the "rosette" or "ring," welded at 500 mm intervals. This rosette has eight apertures: four larger holes to connect primary ledgers at 90-degree angles, and four smaller holes to accommodate diagonal braces or secondary ledgers at various angles. Component ends feature a cast head with a captive wedge pin. After inserting the head into a rosette aperture, the wedge is secured with a hammer blow, forming an exceptionally rigid and precise multi-directional connection.

· System Attributes: The primary benefit of Ringlock scaffolding is its adaptability. Its potential to connect at multiple angles gives Ringlock Unlimited adaptability to adjust to circular tanks, petrochemical installations, some architectural curves, and large stage trusses without the unnecessary effort.

To facilitate a scientific selection, we will conduct an in-depth comparison of the two systems across several criteria critical to engineering practice.

This is the most fundamental point of differentiation between the two systems.

Both systems, when erected correctly, provide a high degree of safety.

A cost analysis must extend beyond the initial procurement price to consider the entire life-cycle value.

|

Performance Dimension |

Ringlock Scaffolding |

Cuplock Scaffolding |

|

Node Structure |

8-port rosette with wedge pin |

Upper/lower cup with ledger blade ends |

|

Flexibility |

⭐⭐⭐⭐⭐ (Excellent, for any complex geometry) |

⭐⭐⭐ (Good, primarily for orthogonal structures) |

|

Erection Speed |

⭐⭐⭐⭐ (High overall efficiency on complex jobs) |

⭐⭐⭐⭐⭐ (Extremely fast on simple structures) |

|

Load Capacity |

⭐⭐⭐⭐⭐ (Exceptional, for heavy-duty shoring) |

⭐⭐⭐⭐ (High, meets most general construction needs) |

|

Core Applications |

Industrial, Energy, Shipbuilding, Venues, Bridges |

High-rise facades, Municipal bridges, Interiors |

|

Long-Term ROI |

Excellent for companies with diverse portfolios |

Good for companies with specialized operations |

In summary, there is no universally "best" system. The optimal choice is derived from the precise matching of system characteristics with project requirements.

The project primarily involves standard high-rise building facades, regular bridge pier construction, or large-area interior birdcage scaffolds.

The project prioritizes speed on structurally simple and repetitive layouts.

The company's business is relatively specialized, without frequent need for extreme scaffolding flexibility.

The project involves complex industrial installations (e.g., oil & gas, power), shipbuilding and repair, irregular architectural surfaces, or large-scale performance stages.

A high-strength, heavy-duty support system is required, such as for cast-in-place concrete slabs or heavy equipment platforms.

As a comprehensive engineering firm, the goal is to use one standardized, universal asset to address diverse market demands, thereby maximizing return on investment.

In conclusion, both Ringlock and Cuplock scaffolding represent outstanding achievements in modular construction technology. Only through a thorough analysis of project needs, combined with a deep understanding of the core advantages of each system, can a truly rational, economical, and safe engineering decision be made.

Can Ringlock and Cuplock scaffolding components be mixed and used together?

Is one system inherently safer than the other?

What is ringlock technology in scaffolding?—— QUORA

What is Cuplock Scaffolding?—— QUORA