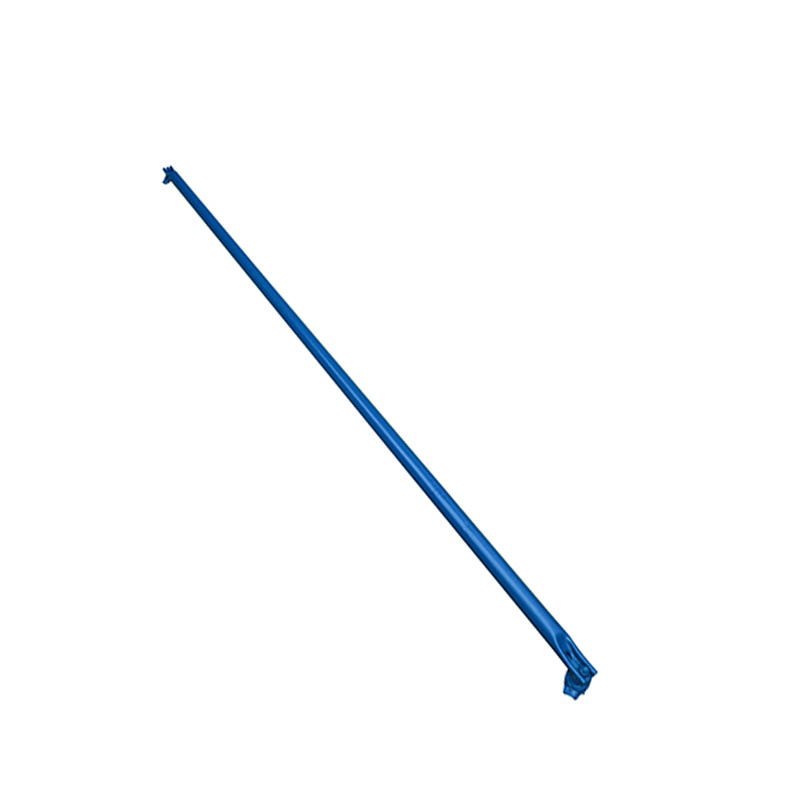

Cuplock Scaffolding Bracing

Cuplock scaffolding can bear weight up to 50% more than traditional scaffolding support systems. These can raise lateral stability by a maximum of 40%, offering assurance of safety and support to scaffolding.

Our cuplock scaffolding supports are in full compliance with international scaffolding safety standards under OSHA, EN, and ANSI regulations, so your workers are guaranteed the safest environment possible. Should you have a need for cuplock scaffolding braces, please contact us.

Features of Cuplock Scaffolding Bracing

-

Stable and High Load-bearing Capacity

Cuplock bracing is designed to enhance resistance to wind forces and has strong bearing capacity, making it a good choice for construction projects in windy conditions or high-risk areas.

Stable and High Load-bearing Capacity

Cuplock bracing is designed to enhance resistance to wind forces and has strong bearing capacity, making it a good choice for construction projects in windy conditions or high-risk areas. -

Damage-resistant

Made of high-quality steel or galvanized materials, cuplock bracing is durable and has a long service life of 25 years or more under normal use conditions.

Damage-resistant

Made of high-quality steel or galvanized materials, cuplock bracing is durable and has a long service life of 25 years or more under normal use conditions. -

Easy to Install and Remove

The precise cuplock system design components can effectively increase the scaffolding assembly speed by 30% and the disassembly speed by 40%, thereby reducing labor costs and project downtime.

Easy to Install and Remove

The precise cuplock system design components can effectively increase the scaffolding assembly speed by 30% and the disassembly speed by 40%, thereby reducing labor costs and project downtime.

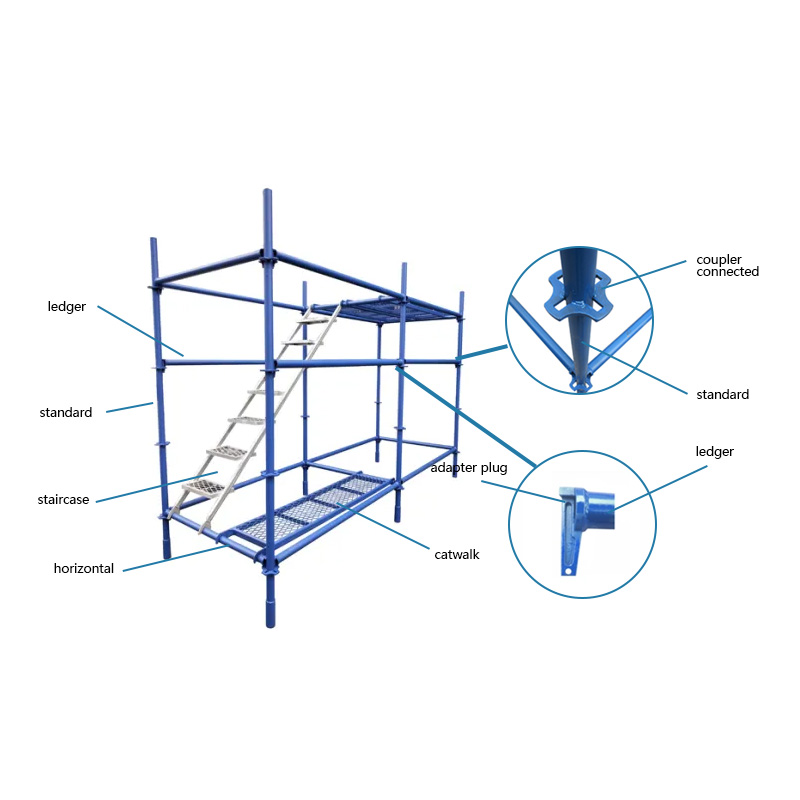

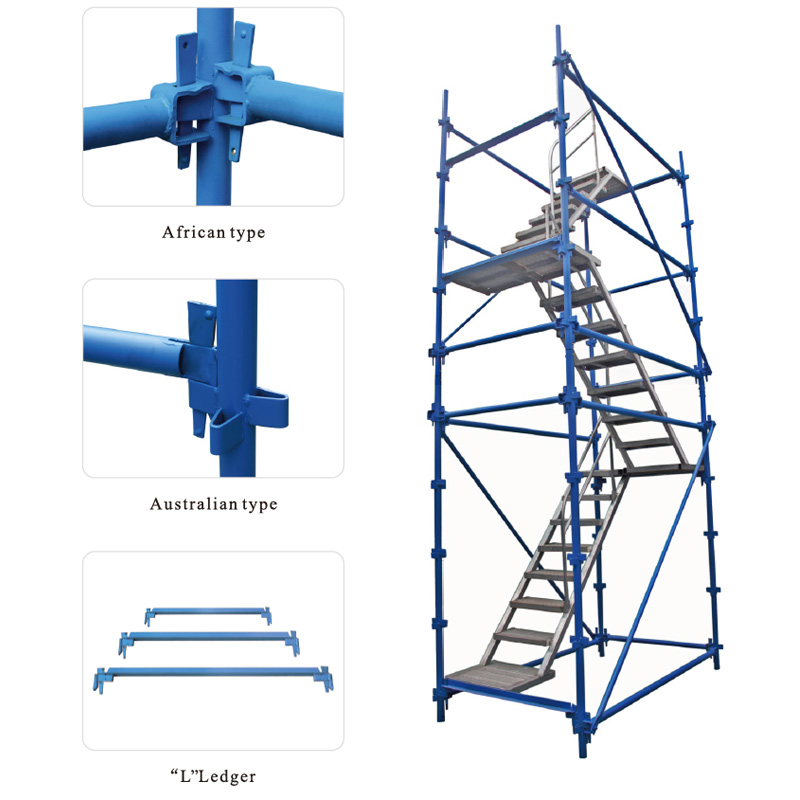

Types of Cuplock Scaffolding Bracing

Swivel Face Blades Type Brace: Unique swivel feature allows for flexible connections and improved stability of the scaffolding system.

Swivel Clamp Type Brace: A clamped mechanism to that feature enables the brace to swivel and offers a better degree of flexibility while still holding tight.

Materials of Cuplock Scaffolding Bracing

Carbon Steel: Carbon steel provides very good tensile strength, therefore making the braces more than good enough to bear heavy loads,, making them perform instead of the light construction.

Stainless Steel: AJ Building utilizes stainless steel for the cuplock braces, which have excellent resistance to both corrosion and abrasion and find applications in projects where exposure to corrosive chemicals or extreme environmental conditions is involved.

Cuplock Scaffolding Bracing Size Specifications

|

Length |

Pipe Diameter |

|

1.5m to 6m |

48mm to 60mm |

|

1m to 6m |

48mm to 60mm |

|

2m to 6m |

48mm to 60mm |

Above are some common sizes of Cuplock scaffolding bracing, if you need customized size, we can also provide related services.

Surface Treatment of Cuplock Scaffolding Bracing

AJ Building offers a variety of surface treatments that allow cuplock scaffolding braces to be aesthetically appealing and lead to substantial improvements in performance.

Hot Dip Galvanized: wherein the steel support is submerged in molten zinc that makes a strong protective coating rendering a great increase in the support's ability to resist rust and corrosion.

Painting: Painting gives scaffolding supports in one color decent resistance to corrosion and is a great choice of aesthetics as well.

Powder Coating: dry powder is applied via electrostatic means and later cured at high temperature, giving a solid protective coat. Providing the aesthetics and color coordination for your cuplock scaffolding braces.

en

en fr

fr es

es