Scaffolding pipes are an important part of the scaffolding system to provide workers with a safe and stable platform. Probably the main factor affecting the strength, stability, and safety of the scaffolding system is the diameter of the scaffolding pipe. Next, we will introduce you to the general standard codes available, their importance, their material impact, and other applications concerning scaffolding pipes, etc., for maximum decision-making on a scaffolding pipe diameter that is fit for the task at hand.

What is Scaffold Pipe?

Also called scaffold tubes, scaffold pipes as the important backbone for scaffolding systems. They are structural components used in the construction and repair of different building projects. They can hold heavy loads and support workers or goods that can avoid bending or breaking.

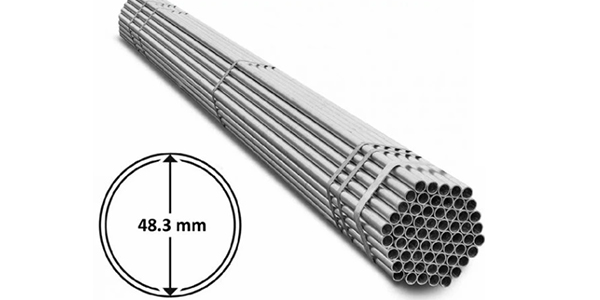

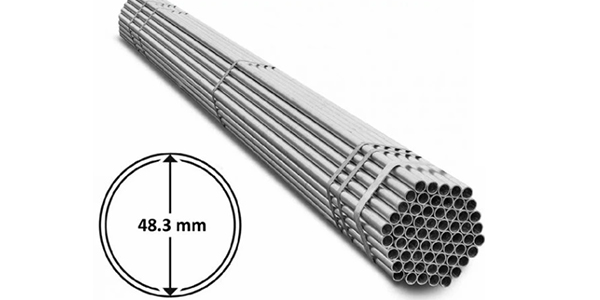

Standard Scaffolding Pipe Diameter

- 48.3 mm (1.9 inches): The tube diameter is mentioned in international standards for pipelines. Most construction projects are always rely on these pipes.

- 38 mm (1.5 inches): Applied for more light or smaller scaffolding structures.

- 60 mm (2.36 inches): Used for heavy-duty scaffolding with specific capacity requirements.

- 21-26 mm (0.83-1 inch): Applied for handrails or guardrails within scaffold systems, limited in load capacity.

Why is The Diameter of Scaffolding Tube so Important?

- Load-bearing Capacity: The diameter of a scaffolding tube determines its ability to bear heavy loads, including construction materials, equipment and workers.

- Structural Integrity: Scaffolding pipes of the correct diameter can resist bending and buckling which can not bend or break easily, maintaining the structural integrity of the scaffolding, thus ensuring that the scaffolding remains stable.

- Compatibility with Accessories: Standard scaffolding pipe diameters (such as 48.3 mm) are compatible with most clamps, couplers and accessories, ensuring seamless integration, making scaffolding systems interchangeable and simplifying the construction process.

- Compliance with Safety Standards: International safety standards such as 48.3 mm usually specify specific diameters for scaffolding pipes, which ensures the safety of scaffolding and reduces the risk of collapse and accidents on construction sites.

Materials and Their Effect

- Steel Pipes: Steel pipe is suitable for heavy construction projects with large loads and high stability. Even steel pipes with smaller diameters (such as 48.3 mm) will not affect load-bearing capacity much. However, steel pipes are heavy, hence the need to take care in enforcing the optimal scaffold pipe diameter size concerning movable ease and utility.

- Galvanized Steel Pipe: The protective zinc coating on galvanized steel pipe increases its lifetime and guarantees resilience in extreme environments. The structural strength may enable a standard diameter of smaller scaffolding pipes to be used in long-term ponies in very humid environments.

- Aluminum Pipe: Aluminum pipes are weaker, forcing the diameter of scaffolding pipes to be quite large to create load-bearing capacities comparable to steel pipes. However, aluminum pipes are much lighter and hence easier to maneuver than steel pipes, and what is more, with their natural resistance to rust, they have less impact on coastal projects and other frameworks.

Standards and Grades of Scaffolding Tubes

- BS 1139 (British Standard): specifies the diameter (usually 48.3 mm) and wall thickness (3.2 mm or 4.0 mm) of scaffolding tubes.

- EN 39 (EU Standard): requires scaffolding tubes to have an outer diameter of 48.3 mm and a minimum wall thickness of 3.2 mm.

- GB/T 3091 (China National Standard): The common size of the general standard is 48.3 mm outer diameter and 3.5 mm wall thickness.

The grades of scaffolding tubes are usually divided into ordinary and high-strength grades based on the strength and quality of the material.

Grades

Standard is simply mild carbon steel with a yield strength of around 235 MPa.Used in scaffolding structures of low load, short duration, and simple. High Strength grade uses high-strength low-alloy steel with a yield strength of about 355 MPa.Used for use in complex structures with high load or longer duration applications.

Which has Higher Durability and Impact Resistance

Galvanizing Grade: The steel pipes for scaffolding are usually EGL/HDG, i.e., hot-dip galvanizing, quite often divided into standard and thick galvanizing, with better corrosion resistance. The thicker the galvanizing layer, the more-life expectancy the scaffolding pipe will have against corrosion attacks. According to ISO 1461, galvanized pipes are likely to prevail longer than others in a humid environment.

Factors to Consider When Choosing Scaffolding Pipe Diameter

- Project Requirements: Different project projects have different diameter standards. High-rise construction usually uses scaffolding pipes with a diameter of 48.3 mm and above, which can have stronger pressure resistance. Short-term or small projects choose smaller diameters (such as 42.4 mm) to meet the needs and save costs.

- Scaffolding Height: The higher the scaffolding height, the greater the bearing capacity (such as heavy equipment, construction personnel, and building materials) that needs to be borne, and the larger the diameter of the steel pipe that should be selected. The specific requirements should be calculated and considered based on the construction load of the scaffolding.

- Pipe Material: Steel has extremely high strength and is usually used for heavy-duty construction. Galvanized steel has a protective zinc coating and can be used in harsh environments.

- Environmental Conditions: If the construction environment has statistical weather conditions (such as strong winds and high humidity), it is recommended to use scaffolding pipes with a larger diameter. Transparent pipes with a diameter of 48.3 mm are a common choice. In confined spaces or complex geometric structures, the scaffolding pipe diameter may need to be adjusted for installation and sensing.

- Budget Cost: Under the premise of ensuring construction safety, choose scaffolding pipes with appropriate diameters to reduce costs. Accurately calculate the number and length of scaffolding to be used according to construction needs to avoid excess materials.

- Comply with Standards: Ensure that scaffolding pipes comply with local and international standards (such as BS 1139 or EN 39). The components selected for the scaffolding system are usually standardized, and the shape should be compatible with the specifications of the connectors (such as snap-ons, joints).

How to Measure the Diameter of Scaffolding Pipes

- Different tools have different methods of measuring scaffolding pipes. When choosing the tools and methods for measuring, one should make the choice based on the diameter, material, and accuracy requirements of the scaffolding pipes.

- Use a vernier caliper and ensure that the surface of the pipe to be measured is clean and free from dirt and other debris at the time of measurement. Place the jaws of the vernier caliper lightly around both sides of the pipe and read off the displayed outer diameter value. Insert the inner measuring jaws of the vernier caliper into the pipe to measure the inner diameter of the pipe.

- Use the measuring rod of the outside diameter micrometer and place it on both sides of the pipe, adjust the knob, and note down the outer diameter value.

- Use any tape measure or a steel ruler; to measure the circumference, wrap the tape around the cross-section of the scaffolding pipe, and use the formula diameter = circumference ÷ π (π = 3.1416) to calculate the outside diameter of the pipe.

- Use the laser measuring instrument and aim this instrument at the outer edge of the scaffolding pipe, switch on the laser, and record the value obtained.

Tips for Choosing the Right Scaffolding Tube Diameter

Consult an Expert: To choose the right tube diameter for your construction project, you should consult with an expert-a scaffolding supplier or engineer.

Match with Fittings: Check that the diameter is compatible with couplers, clamps, and other units.

Consider Future Needs: Use a constant diameter for easy extension, or any other scaffolding system integration.

Conclusion

The choice of scaffolding tube diameter is one of the most important features of a scaffolding system. From safety and compliance to necessary load-bearing capacity, it is a critical decision for successful project execution. Knowing the standards, materials, and possible criteria helps in making an informed decision that will maximize on-site efficiency and safety.

Need help choosing the right scaffolding tube dimensions ? Contact AJ Building for professional advice and a high-quality scaffolding solution that fits your needs.

FAQ

- What are the standard scaffold pipe diameters?

48.3 mm (1.9 inches): Commonly used for most scaffolding systems, it ensures compatibility with industry-standard fittings.

38 mm (1.5 inches): Used for specific lightweight or smaller-scale applications.

60.3 mm (2.4 inches): Utilized for heavier load-bearing structures.

- Can scaffold pipe diameter impact worker safety?

Yes. Incorrect diameter selection can lead to structural instability, increasing the risk of collapse or accidents. Ensuring the proper diameter is critical for safety and compliance.

- Can I customize scaffold pipe diameters for specific projects?

Yes, many manufacturers offer customized diameters to meet unique project needs.

Related Articles

Safety Standards for Scaffolds Used in the Construction Industry ——Occupational Safety and Health Administration (.gov)

Why a 1 ½ Inch Scaffold Tube Does Not Have a 1 ½ Inch Diameter ——apacsafety.com