H Frame Scaffolding Manufacturer

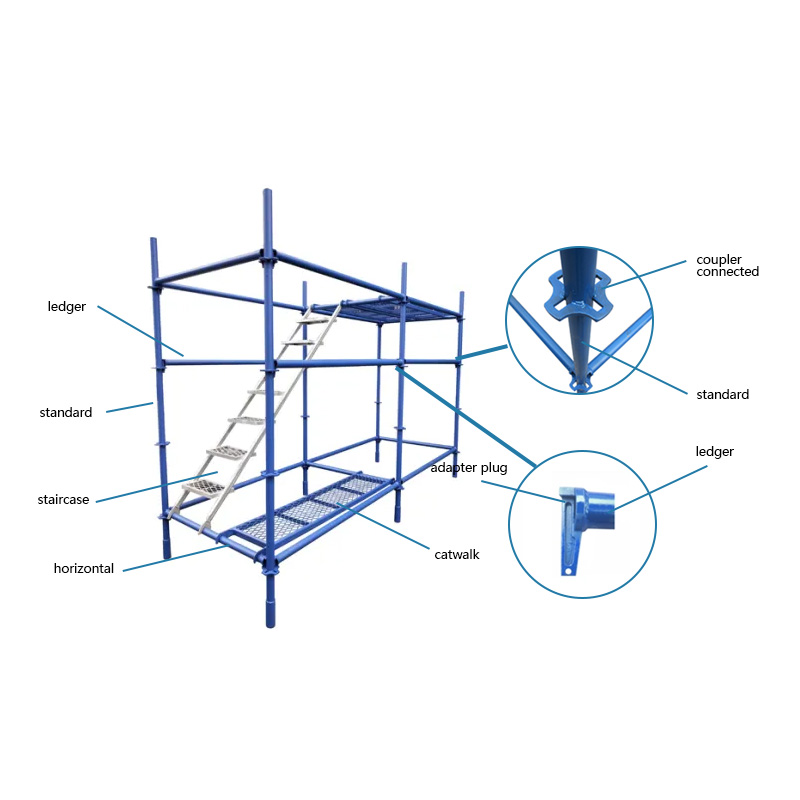

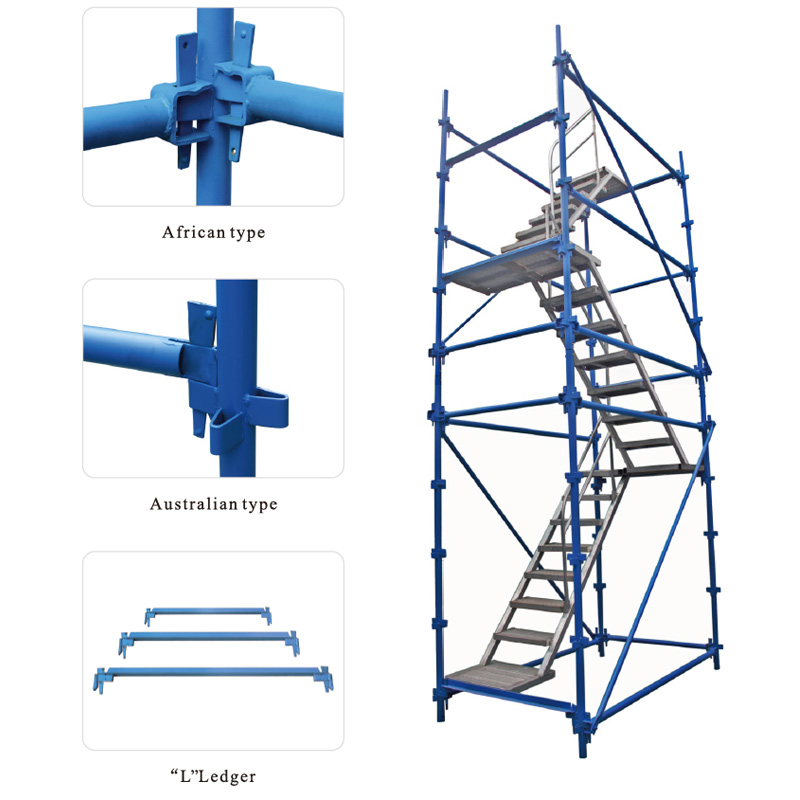

Walk thru H type Frame scaffolding also call door frame scaffolding, scaffolding h, allows workers to operate at different heights and is frequently used in both indoor and outdoor projects. Additionally, its modular design allows for easy assembly and disassembly, making it convenient to transport and set up at various job sites.

AJ Building provides you with standard-sized frame scaffolding and equipped with its accessories. All products include SGS CE ROSH and other certifications. If you are looking for frame scaffolding, please send us an email!

Standard Size H Frame Scaffolding

Based on the hot-selling sizes in the market, we have developed standard sizes for products that can meet more than 90% of engineering projects. If the standard sizes of these products do not meet your needs, please tell us your size and we will customize the product.

| Length(mm) | Width(mm) | Thickness(mm) |

| 1930 | 1219 | 2.0/2.2 |

| 1700 | 1219 | 2.0 |

| 1700 | 914 | 2.0 |

Advantages Of Steel H Frame Scaffolding

These advantages make h scaffolding frame a popular choice for various construction applications.

-

Stability And Strength

This scaffolding structure is known for its stability, providing a secure platform for workers to perform tasks at different heights. The H-shape design reinforces its strength.

Stability And Strength

This scaffolding structure is known for its stability, providing a secure platform for workers to perform tasks at different heights. The H-shape design reinforces its strength. -

Versatility

It's versatile and suitable for various construction projects, including both interior and exterior work. Its adaptable nature makes it usable in different environments.

Versatility

It's versatile and suitable for various construction projects, including both interior and exterior work. Its adaptable nature makes it usable in different environments. -

Accessibility

Workers can easily access different levels and areas, offering flexibility in the construction process.

Accessibility

Workers can easily access different levels and areas, offering flexibility in the construction process.

Surface treatment

In order to extend the service life of the product, in general, the frame scaffolding will be treated with hot-dip galvanizing surface treatment. At the same time, we also provide pre-galvanizing and powder coating surface treatment. In addition, the powder coating surface treatment can be selected in different colors. You can customize the color of the product according to your project.

Application Of Metal H Frame Scaffolding

H frame tower scaffolding, due to its stability and versatility, finds application in various construction scenarios. Common areas of application include:

Construction Sites: Repairing, or renovating structures such as residential buildings, commercial spaces, bridges.

Maintenance Work: Painting, cleaning, or repairs in structures where access is required at different heights.

Industrial Projects: Equipment installation, maintenance, or repairs within manufacturing facilities or warehouses.

Events and Exhibitions: Employed for setting up temporary structures for events, trade shows, concerts, or other large gatherings.

Outdoor Projects: Useful for landscaping projects, outdoor installations.

Interior Work: Deployed for interior construction, ceiling installations.

FAQ

What materials are used in H-frame scaffolding?

- H-frame scaffolding is often constructed using high-quality steel or aluminum due to its durability, strength, and resistance to corrosion.

Is H-frame scaffolding easy to transport?

- Yes, H-frame scaffolding is designed to be easily transportable. Its modular design allows for convenient disassembly and reassembly, making it suitable for multiple locations.

What safety measures should be considered when using H-frame scaffolding?

- Users should ensure that the scaffolding is erected on stable ground, adequately secured, and not overloaded beyond its capacity. Also, proper safety equipment, such as harnesses and guardrails, is essential to prevent accidents.

en

en fr

fr es

es