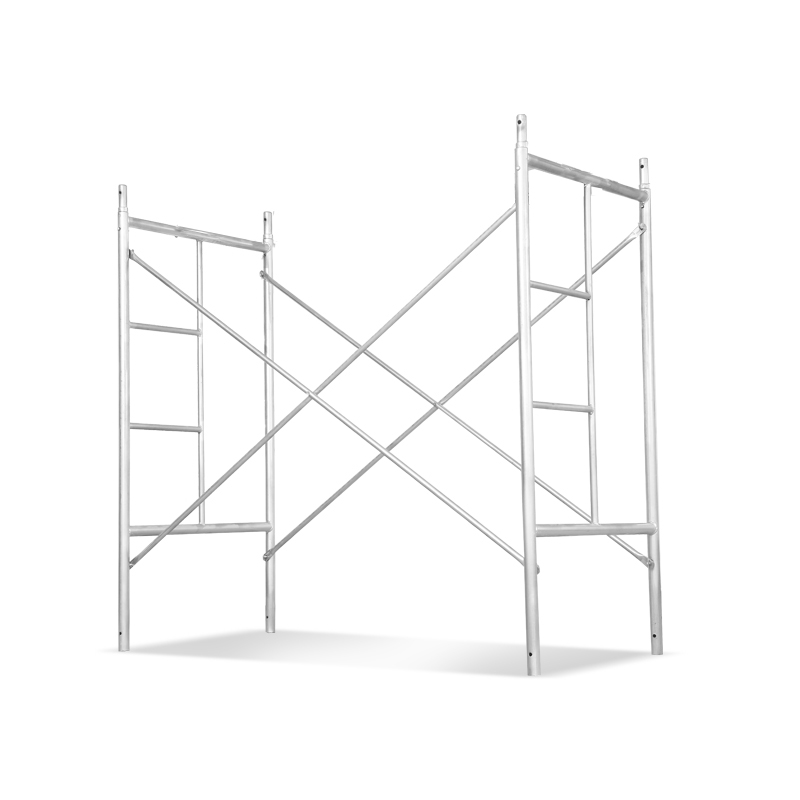

Kwikstage Staircase Manufacturer

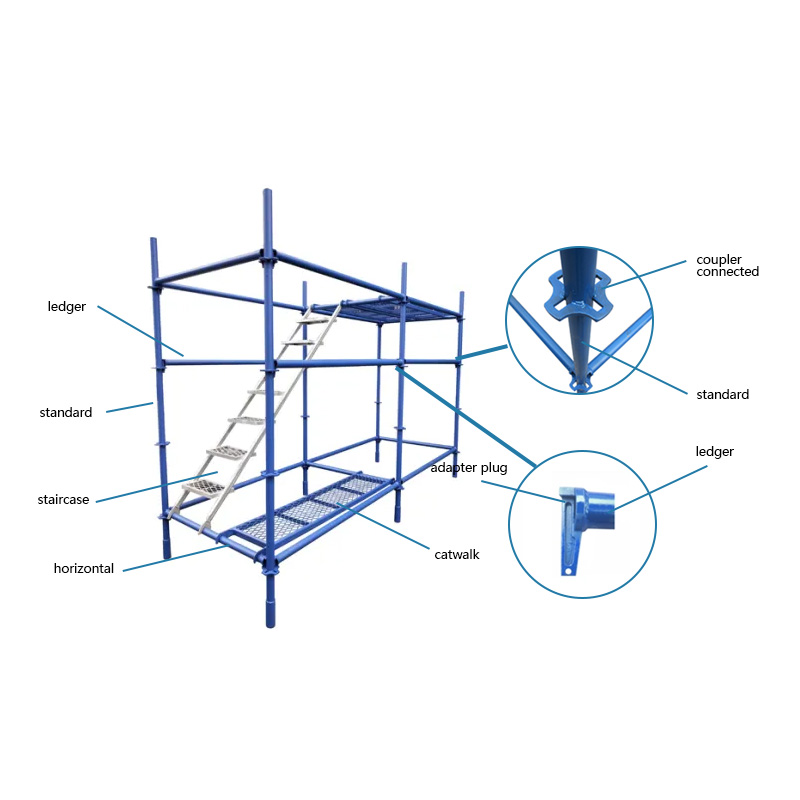

Kwikstage staircase are components of the Kwikstage scaffolding system, roviding a safe, reliable and efficient way for workers working at heights. Designed to integrate perfectly with Kwikstage scaffolding, they are simple to put together and highly durable, serving a purpose in construction, maintenance, and industrial projects alike.

Being a professional manufacturer of Kwikstage staircase, AJ Building can offer you custom sizes, materials, and surface treatments conforming uniquely to your various kinds of projects. Should you need products on Kwikstage staircase, feel free to contact us!

Feature Of Kwikstage Kwikstage Staircase

Kwikstage Staircase Customization

Size Customization

Our Kwikstage staircase has available features for flexible size options and can be customized according to customer needs. Some of the common standard sizes include:

- 2500 x 2000 x 500

- 2500 x 1500 x 500

Through the provision of customized sizes, we shall ensure that the staircase is tailored to fit your Kwikstage scaffolding system, alongside fulfilling the project's peculiar requirements.

Material selection

To ensure the staircase system can serve its intended purpose over time, we provide for customers of our products two basic choices for construction materials- steel and aluminum:

- Steel : made from high-strength steel; has excellent tensile strength and impact resistance, and is traditionally used in applications with heavy-duty engineering requirements; and

- Aluminum: light weight and corrosion resistant; suited for high-weight requirement projects, and capable of withstanding normal construction loads.

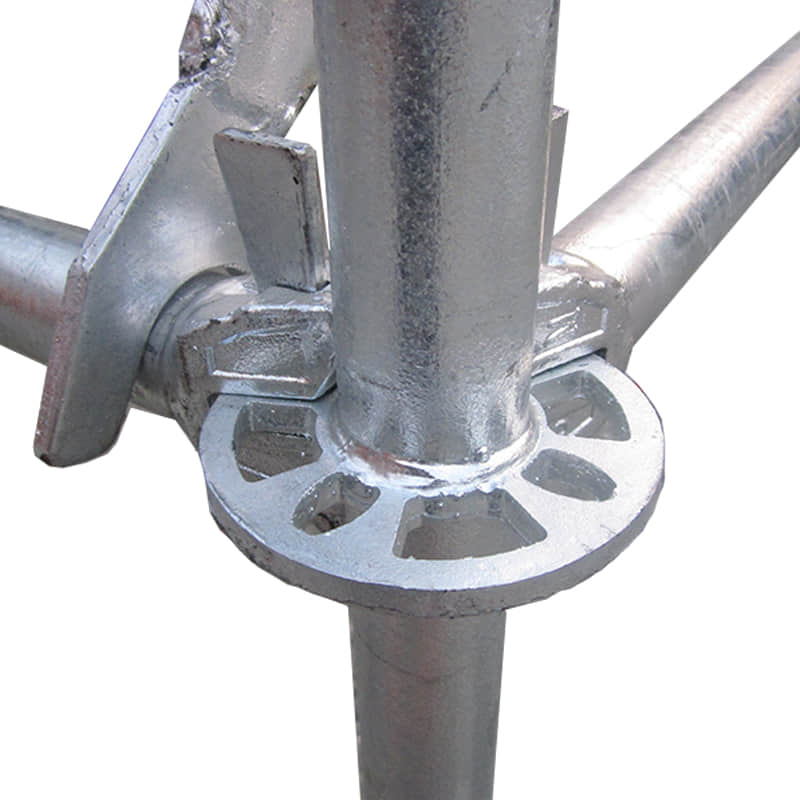

Surface Treatment Process

We offer the following choices of surface treatments tailored for a diversity of uses to enhance the long-term functioning serviceability of the kwikstage staircase systems in such HVAC environments.

- Steel hot-dip/electro-galvanizing: Provides an advanced level of corrosion resistance of the system primarily beneficial for use outdoors and other more hostile environments.

- Powder coating: To provide high performance and aesthetic appearance while increasing its resistance to wear, with the option of colors depending upon the project aesthetic, of which beauty and durability are primary considerations.

These surface treatments exhibit not only a desirable appearance, but also long-term operational flexibility, enhancing product life.

en

en fr

fr es

es