Ringlock vs Kwikstage Scaffolding Roi Guide

Oct 14, 2025

Introduction

In the construction and engineering industries, selecting the correct temporary access system is vital. It has a direct effect on the programme of the project, site safety, and, most importantly, cost. Two systems of modular scaffolding dominate the worldwide marketplace by virtue of their versatile qualities and efficiency these are Ringlock scaffolding and Kwikstage scaffolding. In the case of the construction and engineering companies, the decision is a simple one in terms of speed, safety compliance, and the important question of return on investment (ROI). In the case of the builders’ merchants, the question is one of market demand, stock control, and the provision of the most saleable product. The aim of this detailed comparison is to delineate more closely the two types of scaffolding, Ringlock and Kwikstag, and to arm you with the detailed knowledge to enable you to make the correct choice, the one that brings good profit and site efficiency.

SYSTEM SCOPE AND CORE TECHNOLOGY

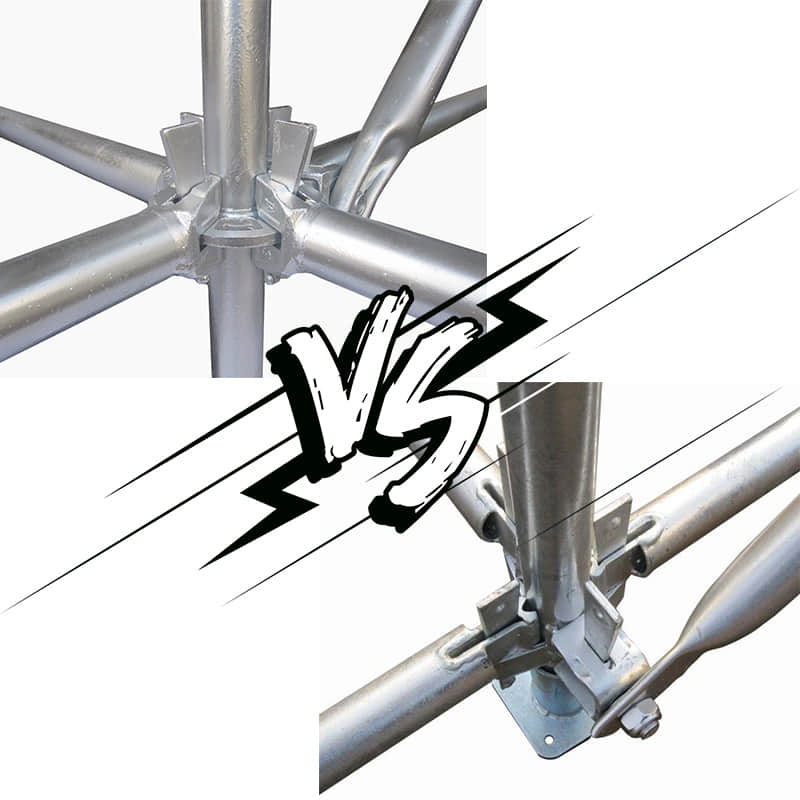

Both Kwikstage and Ringlock are modular scaffold systems, meaning they are composed of pre-manufactured parts that can be quickly locked into position. However, the way in which these parts go together is very different, and the application and performance are therefore quite different.

1. Ringlock Scaffolding: The Versatile Heavyweight

Ringlock is characterized by a unique rosette (ring) welded every 0.5 meters to the standards (vertical posts). There can be up to eight connections on one point using ledgers (horizontal) and diagonal braces, giving unrivaled versatility to irregular geometries.

Notable Feature: The multi-directional eight-hole connection point.

Best Use: Circular, curved, high-rise, and heavy-loading uses such as industrial plants and major infrastructure projects.

2. Kwikstage Scaffolding: The Speedy Classic

Kwikstage (also known as Cuplock in some markets, but slightly differently) utilises a distinct V-pressing or wedge-fixing system. The ledgers and transoms are connected to the standards by means of a series of fixed or movable cups or wedges. The system is generally bi-directional.

Key Feature: It's simple, rapid 'wedge-and-cup' or 'V-press' means of connection.

Best Suited For: Straight, symmetrical façades, and residential and commercial buildings where maximum erection speed is the first consideration.

Head-to-Head Comparison for Construction Efficiency

Feature

Ringlock Scaffolding

Kwikstage Scaffolding

Impact on Construction Firms

Erection Speed

Moderate to fast. It necessitates a bit more precision when you brace in more than one direction.

Extremely fast. Easy, rapid, positive connections enable speedy installations.

Essential for projects with custom architectural features (i.e., historic preservation, modern aesthetics).

Versatility & Adaptability

High. Multi-directional connections allow it to easily follow curved walls, complex angles, and internal structures.

Medium. Primarily designed for straight lines and standard building shapes. Adaptations for curves are often cumbersome.

Critical for projects with unique architectural features (e.g., historical restorations, modern designs).

Load-Bearing Capacity

Very High. Sturdy rosettes and excellent bracing systems enable it to carry more vertical and horizontal loads.

High. Good for most general construction loads, but not very adaptable for extremely heavy-duty industrial purposes.

Essential for heavy cladding, concrete pouring, and any multi-story structure that involves a large amount of material storage.

Component Count

In general, due to the versatile nature of the rosette connection, the number of primary parts is smaller.

A larger number of parts is required for bracing and accessories to cover complex areas.

These factors affect inventory control, transport costs, and loss of parts.

The Trader's Perspective: Marketability and Investment

For those who trade and distribute building materials, the decision to buy is a business decision contingent on inventory turnover, demand for the product, and the long-term viability of the product.

1. Market Demand and Geographic Trends

Ringlock: This is the global standard in high-end industrial, commercial, and infrastructure projects and is the preferred option in many emerging markets and companies that focus on safety certifications (OSHA and EN standards, etc). The trend is towards Ringlock with its long-term versatility.

Kwikstage: Has a good hold in certain established markets (especially the UK, Australia, and South Africa) where residential and low to mid-rise commercial sectors are concerned, as familiarity and speed are highly valued.

2. Inventory and Durability ROI

Durability: The construction of Ringlock - particularly its strong connections and often hot dip galvanised finish - means that it usually exhibits greater durability and less long-term replacement costs than, for example, Securock. Higher initial cost but better long-term return on investment.

Stocking: The components of Kwikstage are normally individual to that system and are not easily interchangeable. The elements of Ringlock generally consist of more standard components operating from different manufacturers, thus aiding compatibility and facilitating the stock control of dealers.

Rental Profitability: Because Ringlock can be employed in a much wider field of high-value, complex work than it is able to be employed in, it commands a higher rental rate and has not the same saturation in the market, which certainly points to greater rental profitabilities for hiring houses.

Safety and Compliance – The Non-Negotiable Factor

Both systems, when well put together, are extremely safe and compliant with International Standards. However, the difference in design has an impact on the ease of compliance as follows:

Ease of Inspection: The open nature of the Ringlock connection makes it very easy for safety officers on site to see and check that all connections are secure.

Guardrail Integration: Both systems integrate guardrails, but Ringlock’s multi-directional adaptability allows for the much easier and safer construction of handrails around irregular shapes or penetrations.

Stability: Ringlock’s eight directional bracing, correctly applied, gives superior stability, a factor of immense importance in the construction of tall or heavily loaded structures.

Conclusion: Making the Right Choice

The choice between Ringlock and Kwikstage is not about which system is inherently "better," but which is better suited for your business model and project portfolio.

Scenario

Recommended System

Rationale

Complex, High-Rise, or Industrial Projects

Ringlock

Superior load capacity, versatility for complex geometries, and better long-term ROI.

Simple, Straight-Run Residential/Commercial

Kwikstage

Unbeatable erection speed, lower initial investment, and market familiarity in certain regions.

Material Trader (Future-Proofing Inventory)

Ringlock

Alignment with global trends, higher rental potential, and better adaptability for specialized projects.

The transition towards modular, safety-compliant scaffolding is clear. Whether you choose the structural versatility of Ringlock or the rapid deployment of Kwikstage, ensure your decision maximizes site safety, minimizes labor costs, and provides the best possible return on your investment.

Maximize Your Project ROI Today:

Ready to upgrade your temporary access systems? Contact our experts for a customized consultation on which modular scaffolding system—Ringlock or Kwikstage—best fits your next project's specific demands, budget, and safety requirements. Get a detailed quote and start building smarter, faster, and safer!

FAQ

Which system is faster to install?

Kwikstage is generally faster for simple, straight-line projects. Ringlock is more rapid for complex, curved, or multi-angled structures due to its multi-directional connection.

Which one is better for heavy loads and high-rise projects?

Ringlock. Its eight-way rosette connection allows for superior, multi-directional bracing, providing greater stability and a higher load-bearing capacity, ideal for heavy-duty applications.

Which system is a better long-term investment for a material trader?

Ringlock. It serves a wider range of high-value, complex projects, aligns with global market trends, and often features superior durability (leading to better long-term rental ROI).