What is Supported Scaffolding? Types, Pros, Cons, and Uses

Dec 24, 2025

Safety and efficiency when working from heights are critical aspects of the construction industry. Access can be achieved through a variety of methods, including aerial lifts, suspended platforms, etc., but the traditional way of working platform, known as a supported scaffold, has remained the most basic and globally used method of access for contractors across the world.

If you're in the position of a construction manager, scaffold rental company, or procurement officer within an industry, learning how supported scaffolding functions, its advantages, and what it cannot do provides a foundation to plan your projects properly; With this guide we will provide you with all the information necessary to choose the correct equipment when you decide to purchase supported scaffolding for the next project that you work on.

What is Supported Scaffolding?

Supported scaffolding is the category of scaffolding that supports one or more platforms using rigid load-bearing members (poles, legs, frames, uprights, posts, outriggers, etc.) to support the platform and all materials, tools, and workers performing on top of that platform.

In contrast to suspended scaffolding, which is hung from an overhead support post (as in window-washing scaffolds), supported scaffolding is placed on solid ground and provides all of the necessary weight-bearing support to safely transfer the combined weight of workers, tools,s and materials to the ground.

In addition, it is the accepted industry standard for structural construction, heavy masonry projects, and many long-term maintenance projects in which the types of loads being placed on the scaffold will require high levels of stability and load-bearing.

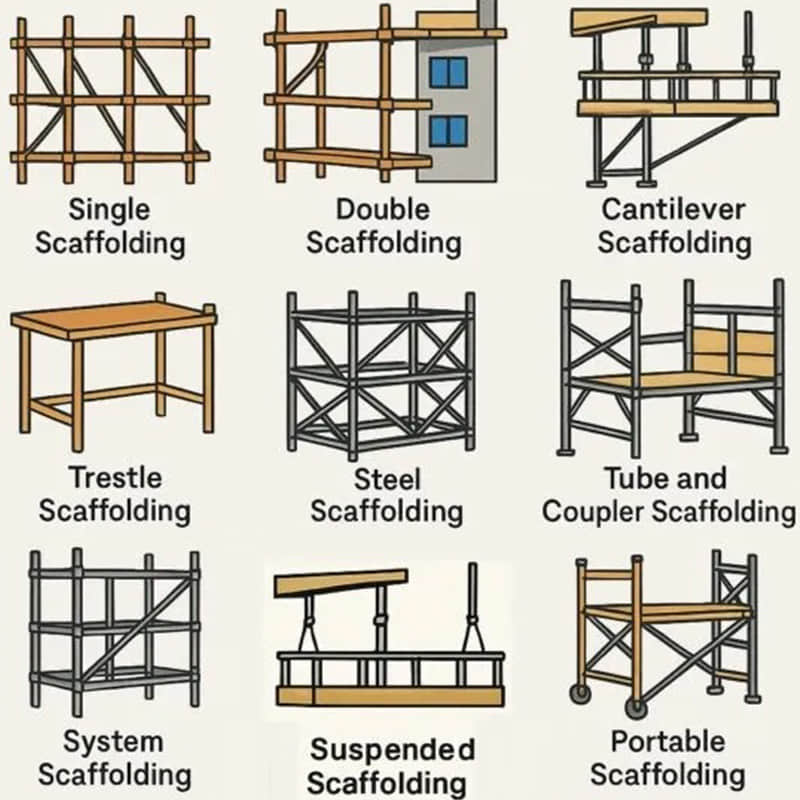

Supported Scaffolding Types

Supported scaffolding is not a "one-size-fits-all" solution. It comes in various configurations designed to meet specific architectural challenges.

1. Fabricated Frame Scaffolding

Often referred to simply as "frame scaffold," this is the most common type seen on residential and light commercial sites. It consists of pre-fabricated metal frames connected by cross braces.

Best feature: Extremely fast to erect and dismantle.

Ideal for: Linear walls, masonry work, and plastering.

2. System Scaffolding (Modular)

System scaffolding, such as Ringlock, Cuplock, or Kwikstage, uses vertical posts and horizontal ledgers that connect at fixed node points.

Best feature: immense flexibility and high load capacity.

Ideal for: Industrial plants, complex geometries, bridges, and circular structures.

3. Tube and Clamp Scaffolding

This traditional method uses steel tubes and couplers. There are no pre-set locking points, allowing for infinite adjustability.

Best feature: Can be adapted to fit any shape, no matter how irregular.

Ideal for: Refineries and areas with heavy obstruction (pipes/ductwork).

4. Mobile Scaffolding (Rolling Towers)

These are freestanding supported scaffolds mounted on castors (wheels).

Best feature: Portability.

Ideal for: Maintenance tasks (painting, electrical) where the crew needs to move frequently across a flat floor.

What Are the Advantages of Supported Scaffolding?

The reason why engineers and site managers continue to utilize supported scaffolding instead of newer technologies is simple: Supported scaffolding provides an incredibly stable, safe platform with the most significant type of load-bearing capacity.

1. Outstanding Stability and Safety

Supported scaffolding consists of a grounded system where everything is secure—that is, there is no sway, and everything is completely secured. This stability gives workers the necessary balance to perform tasks that require great precision and accuracy, such as bricklaying and welding, which is critical to producing quality work.

2. High Load-Bearing Capacity

When it comes to aerial lifts, weight limits will be set (in most cases, only two workers and their tools can fit on them). Supported scaffolds—specifically those classified as heavy-duty system scaffolding—are built to withstand far more weight than aerial lifts. As such, they allow workers to store pallets of bricks, mortar, steel beams, and multiple crew members on a single scaffold system at the same time.

3. Ample Working Surface

Supported scaffolding allows for easy movement throughout the working surfaces of a building. This type of scaffolding supports a continuous working platform along the length of a building, allowing workers to walk along the length of the building without having to stop to adjust equipment, greatly improving productivity.

4. Long-Term Value and Durability

For rental companies, supported scaffolding, mainly supported by hot-dipped galvanized steel, has very high Return on Investment (ROI) values. Supported scaffolding is weather-resistant, remains usable for many years, and requires little maintenance.

What Are the Disadvantages of Supported Scaffolding?

To make an informed decision, one must also consider the limitations.

1. Foundation Requirements

Supported scaffolding needs a stable foundation in order to be effective. A stable foundation consists of a level area with sufficient support to provide stability while it sits on top of the ground. So, where the surface is not even or if the soil is weak, scaffoldings are built using mudsills and base plates, which will help to minimize the risk of the supported scaffolding either sinking or tipping over.

2. Large Footprint

When a supported scaffolding is being built from the ground up, the bottom of the scaffolding has physical space taken up. In dense, crowded cities where there is not enough room for scaffolding to be located on the sidewalk or in front of a building, special permits and pedestrian safety tunnels should be obtained.

3. Erection and Dismantling Time

Unlike a boom lift, which can be operated and used immediately upon being delivered to its "job site, supported scaffolding requires that a qualified person construct it. Therefore, erecting supported scaffolding and disassembling it after the project has ended requires more skilled labor, which can increase the initial labor costs.

What Are the Uses of Supported Scaffolding?

The versatility of supported scaffolding makes it ubiquitous across several sectors.

1. General Construction & Civil Engineering

From high-rise residential blocks to office complexes, supported scaffolding is used for structural work, façade installation, bricklaying, and window installation.

2. Industrial Maintenance

In power plants, oil refineries, and chemical factories, system scaffolding is used to access boilers, smokestacks, and piping systems for routine maintenance and shutdowns.

3. Infrastructure Projects

Bridge construction and repair rely heavily on supported scaffolding to create platforms for workers to operate under or alongside the bridge deck.

4. Shipbuilding and Marine

Supported scaffolds are erected around ship hulls in dry docks, allowing teams to weld, paint, and repair massive vessels.

5. Temporary Public Structures

Interestingly, the same components (especially Ringlock systems) are often used to build temporary grandstands, stages, and lighting towers for concerts and sporting events.

Conclusion

In the construction industry, supported scaffolding is used predominantly. Even though planning for supported scaffold foundations and assembly time is important, there are benefits of using supported scaffolding, including superior stability, capacity for high loads, and increased safety, which can make it the best choice for medium-to-large-sized projects. Supported scaffolding will help ensure crew safety when you are a contractor, or grow your rental inventory when you are a rental company; therefore, making the proper supported scaffold selection will be one of the most critical aspects of successfully operating your business.

Upgrade Your Scaffolding Solutions Today

Are you looking for reliable, certified, supported scaffolding for your next project? Or perhaps you need to restock your rental inventory with high-quality frames and modular systems?

[Contact Our Team] today for expert advice and a competitive quote tailored to your specific needs.

FAQ

What is the maximum height for supported scaffolding?

Theoretically, supported scaffolding can be built to significant heights, provided the base is strong enough. However, standard safety regulations (like OSHA) dictate a strict height-to-base ratio (typically 4:1) to prevent tipping. If a scaffold exceeds this ratio, it must be restrained from tipping by using ties, guys, or braces to secure it to the building structure. For extremely tall structures (over 125 feet), a professional engineer is usually required to design the system.

How often must supported scaffolding be inspected?

According to safety standards, supported scaffolding must be inspected by a "Competent Person" before each work shift and after any occurrence that could affect a scaffold's structural integrity (such as a storm or impact). Regular inspections ensure that base plates are stable, connections are tight, and no components are damaged.

Can I mix scaffolding components from different manufacturers?

It is generally not recommended to mix components from different manufacturers, even if they look similar. Slight variations in tolerance, steel grade, or locking mechanisms can compromise the structural integrity. If mixing is necessary, it must be approved by a qualified engineer to ensure the mixed components fit together safely and maintain load capacity.