Cuplock Horizontal Manufacturer

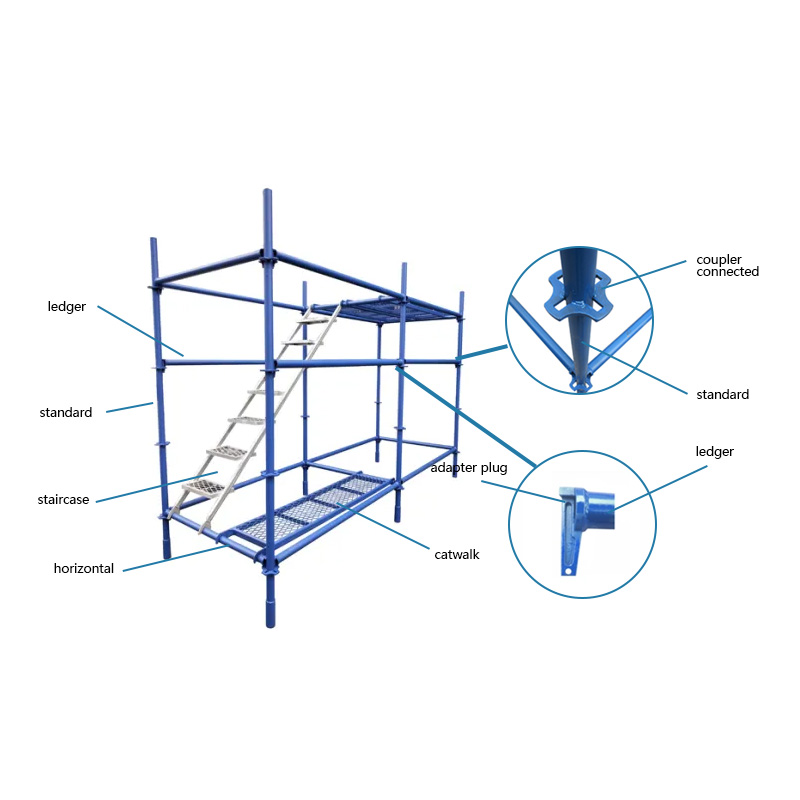

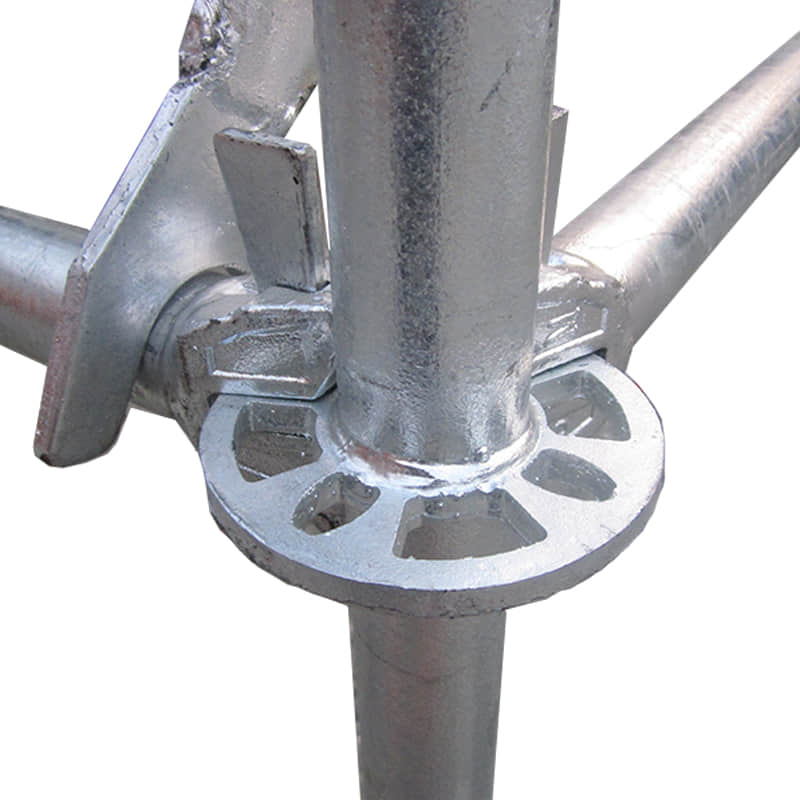

Cuplock horizontal, as the name implies, is a horizontal connecting rod in the cuplock scaffolding system. It is connected to the "cuplock" welded on the vertical rod through the "plugs" at both ends of the horizontal rod to form a stable frame structure. The length of the horizontal rod determines the spacing of the scaffolding and is the skeleton for building the working platform and supporting structure.

AJ Building provides you with cuplock horizontal in different specifications and with different surface treatments. We also provide other scaffolding and accessories to assemble the right scaffolding system for you.

Advantages

Features

-

High bearing capacity

Made of high-strength steel, the crossbar can withstand huge vertical and horizontal loads, ensuring the overall stability of the scaffolding.

High bearing capacity

Made of high-strength steel, the crossbar can withstand huge vertical and horizontal loads, ensuring the overall stability of the scaffolding. -

Easy assembly & disassembly

No bolts or clips are required, just simple insertion and rotation to complete the connection, significantly improving construction efficiency.

Easy assembly & disassembly

No bolts or clips are required, just simple insertion and rotation to complete the connection, significantly improving construction efficiency. -

Versatility and flexibility

It can be combined with vertical poles, diagonal rods, and other accessories of different lengths to form scaffolding structures of various shapes and heights according to construction requirements.

Versatility and flexibility

It can be combined with vertical poles, diagonal rods, and other accessories of different lengths to form scaffolding structures of various shapes and heights according to construction requirements.

Product Specifications

As a powerful manufacturer, our products meet international standards and have CE, SGS/TUV certification to ensure product quality. The following are standard sizes of products. If you have special size requirements, we support customization.

Material: Q235, Q345 high-strength carbon structural steel

Tube diameter: 48.3mm

Wall Thickness: 2.5 mm to 3.5 mm

· 2.5 mm: Suitable for general light or medium construction.

· 3.0 mm: More common, balances strength and cost, and is suitable for most construction projects.

· 3.2 mm or 3.5 mm: Suitable for heavy construction, high-rise scaffolding, or projects with higher requirements for bearing capacity.

Length: 0.5 m , 0.6 m , 0.9 m , 1.2 m , 1.5 m , 1.8 m , 2.0 m , 2.4 m , 2.5 m , 3.0 m

Surface Treatment

- Hot-Dip Galvanized: Hot-dip galvanizing forms a thick zinc layer that provides excellent protection against rust and corrosion, greatly extending the service life of the rail, especially for outdoor and wet environments.

- Electro-Galvanized: Also known as cold galvanizing, the anti-rust effect is not as good as hot-dip galvanizing, but the cost is lower, and it is suitable for indoor or short-term use.

- Painted: The lowest cost, but the rust-proof effect is limited. It is usually used for projects with low appearance requirements and short service life.

Applications

¤ Construction: high-rise buildings, residential buildings, commercial complexes, bridges, tunnels, etc.

¤ Industrial facilities: power plants, petrochemical plants, shipyards, maintenance platforms, etc.

¤ Stage construction: large-scale concerts, event background frames, stands, etc.

¤ Decoration projects: indoor and outdoor decoration, curtain wall installation, etc.

Why choose our cuplock horizontal?

1. Quality Assurance: We select high-quality raw materials and adopt advanced production technology to ensure that each crossbar meets high strength and durability standards.

2 . Complete specifications: We provide crossbars of various lengths and wall thicknesses to meet the needs of different construction projects.

3 . Strict quality inspection: Each batch of products undergoes strict quality inspection to ensure product quality.

4 . Professional service: Our team will provide you with professional consultation and solutions. Welcome to consult.

5. Competitive price: We offer competitive prices without compromising quality to help you optimize your project budget.

en

en fr

fr es

es