Column Plastic Formwork Factory

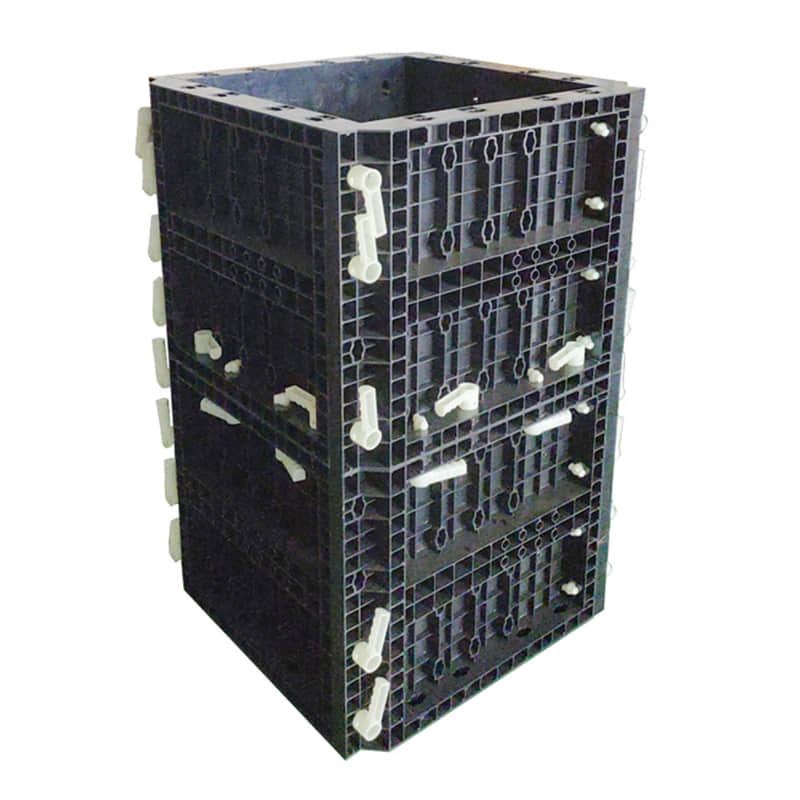

Plastic column formwork is light in weight and extremely tough, easy to erect and reusable. Two types of column plastic formwork are known: round and square column plastic formwork, deployed in various forms of construction projects. Column plastic formwork is made primarily of ABS, and the sizes for this product are from 12 inches to 30 inches. We can customize the diameter, thickness, and height according to your specifications. Besides, product accessories required for the project include Tie-Rod, Pull-Push Props, etc.

Are you looking for column plastic formwork? Contact us now!

Feature Of Plastic Column Forms

- Efficient construction: It is the fastest way to make cylinders, significantly improving construction speed.

- Easy installation: Assembly is quick and easy by simply turning the handle or tightening the bolts.

- Easy to store: The templates are easy to stack on each other during transportation and storage to save space.

- Ultra-high durability: can be reused more than 100 times, which can reduce long-term construction costs.

- Strong pressure bearing capacity: The maximum allowable fresh concrete pressure is up to 80 kN/m2, which can meet the needs of high-intensity construction.

- Easy demoulding: Concrete will not stick to the plastic surface, forming a smooth surface.

Specifications

Material: PVC, ABS, PP

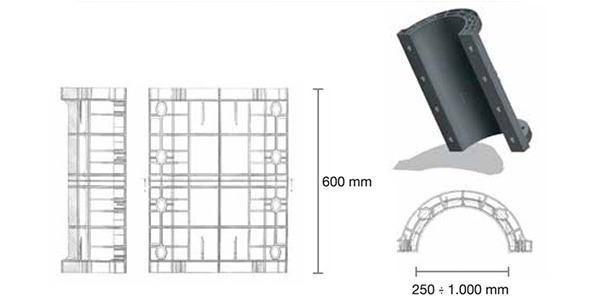

Square/Rectangular Column Sizes: Can form columns with side lengths ranging from 200mm to 1200mm (8 inches to 48 inches) and often in adjustable increments. Panels typically come in heights from 600mm to 1200mm (24 inches to 48 inches) or higher, which can be stacked.

Round Column Diameters: Available for forming circular columns with diameters ranging from 250mm to 1200mm (10 inches to 48 inches) or more. Panels are typically curved segments that join to form the full circle.

Column Plastic Formwork Application

We have cooperated with more than 160 countries and regions around the world and have rich experience in project engineering. Plastic column formwork is widely used in the following scenarios. If you want to know more about our project cases, please send us an email:

Commercial buildings: Recommended for concrete column construction; Residential projects: Enhance building speed and aesthetic quality of structure;

Bridge and Infrastructure: Equipped with strong support.

Precast concrete: Provide fast production of precasts while maintaining quality consistency.

Formwork Accessories

- Pacer: A device for maintaining the spacing between the formwork to ensure the accurate diameter of columns and a stable connection of the templates.

- Tie-Rod: Provides lateral support to fix and serve as a brace. It prevents the buckling of formwork by rigidly holding it against the pressure of the concrete.

- Wing-Nut: Used for the fitting of tie-rods. It can be tightened, locked, and released manually in one rotation for improved efficiency of the installations.

- Steel Waler: In addition to strengthening the formwork, and enhancing bending strength and stability, it adapts to higher concrete pressures.

- Pull-Push Props: Used for vertical adjustment and control of verticality and alignment of formwork to ensure accurate, stable, and reliable column forming during construction.

en

en fr

fr es

es