Formwork is a critical component of construction; they serve the essential purpose of supporting concrete structures until they gain sufficient strength. Numerous hazards related to formwork have considerable implications regarding the level of risk constituted to workers and projects when not managed properly. In this blog post, we will discuss the various forms of hazards involved with formwork construction, reiterate the modalities that can be employed to mitigate the hazards, and zero in on the legalities involved. By following these methods, you could create a safer, better construction site.

Common Hazards in Formwork Construction

Structural Instability

In the catastrophe of formwork failing or collapsing, considers one of the most dangerous incidences on the construction site. These could be:.

- Overloading: Some action or condition increases loads on a formwork system above its limit.

- Inadequate Bracing: Sudden failure occurs in the presence of weak or poorly installed braces.

- Poor Assembly: Misalignment, poorly secured fastenings, or poor installation may increase the potential for instability.

- Early Removal: Premature detaching before the concrete takes adequate strength can cause weakness or worse.

All parts shall be fixed together properly and proper load distribution calculated before concrete is placed in order to avoid structural failure.

Falling Materials

Loose panels, tools, or debris falling from elevating formwork can result in great hazards to the worker below. The reasons for this are:

- Unsecured parts-Such as panels, clamps, or connectors that are loosely fastened.

- Vibration-Objects will start shaking due to machine operations or concrete pouring.

- Lack of a barrier-protective devices are basically insufficient to prevent the falling materials from getting to the workers at the lower levels.

The installation of safety nets, toe boards, and proper tying of materials will greatly reduce the risks posed by falling hazards.

Manual Material Handling Injuries

When heavy concrete forms are handled without the proper type of equipment or the necessary techniques, there can be:

- Muscle strains resulting from lifting heavy panels;

- Injuries occurring to the lower back, usually from poor posture or additional effort;

- Crush injuries suffered as a result of an assembly or adjustment being made to formwork while the load was on it.

The use of mechanical lifting aids, proper training on lifting techniques, and ergonomic work practices can minimize manual handling risks.

Load Failures

Formwork that cannot withstand fresh concrete pressure may buckle or collapse across. It occurs due to:

- Concrete pressure underestimated: Wet concrete applies vast lateral force; thus, a strong support is required.

- Material fatigue: Over time, reused formwork parts can lose strength.

- Environmental stresses: Wind and temperature modes can adversely affect material strength.

Making proper calculations for the applied loads and application of good-quality materials are ways to avoid structural failures.

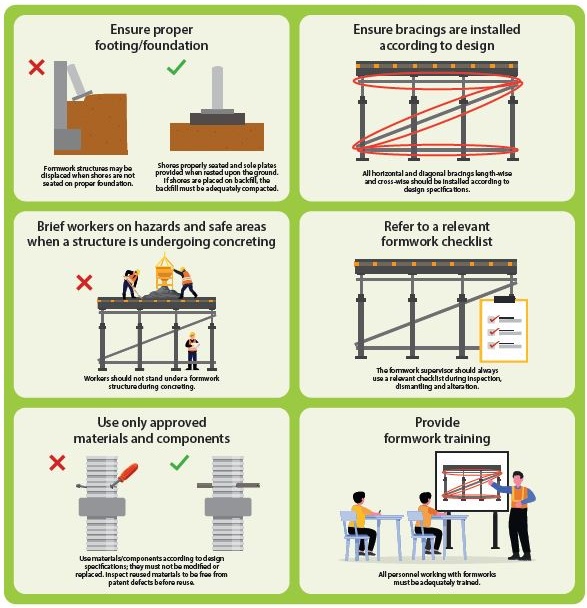

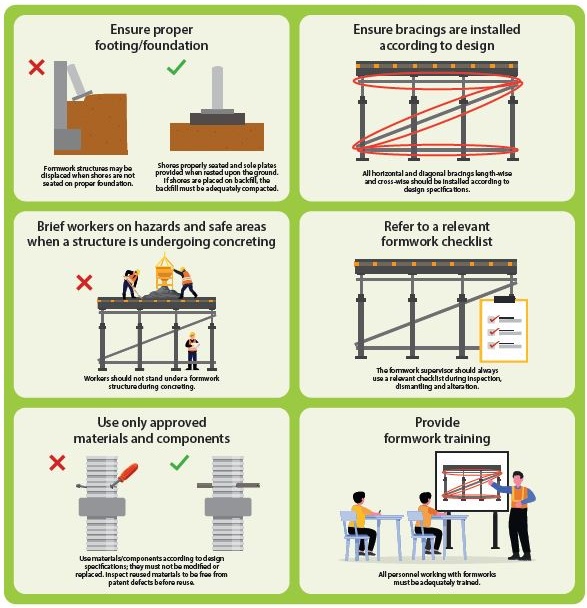

Best Practices for Formwork Safety

Training and Supervision

Supervised training is a must for workers working with formwork systems. Special attention should be on the following:

- Installation procedures - correct methods of assembly.

- Hazard awareness - different conditions under which hazards apply.

- Emergency response - respect for procedures to be followed for any type of structural failure.

Supervisors must ensure that workers follow safety procedures, along with experienced personnel overseeing critical formwork operations.

Regular Inspections

Frequent inspections often help pinpoint weak spots that haven't become hazards yet. Inspection should cover:

- Structural integrity-checking for cracks, misalignments, or loose fastenings.

- Load-bearing capability-assuring placement of loading is within fragile limits.

- Environmental impact-monitoring conditions of weather and climate that will affect the formwork's stance.

The inspections should occur before, during, and after concrete pouring.

Material Quality and Maintenance

Durability and strength of the components of formwork have a direct linkage to safety. Best practices involve the following:

- Use certified materials that meet industry standards.

- Inspect reuse components for degradation or damage.

- They should be stored right so that they would not warp or weaken due to moisture exposure.

Higher grades of materials can minimize failure factors during concrete pouring.

Prop and Bracing

Best support systems contribute to avoiding collapse. Important considerations to keep in mind are:

- Spacing and alignment – Ensuring even weight distribution.

- Secure fastenings – Using strong connectors to prevent movement.

- Adjustments during pouring – Monitoring shifting loads to prevent instability.

Using adjustable supports allows for real-time load management and enhanced stability.

Worker Safety Measures

Protective Equipment

PPE are meant to reduce injuries. The mandatory equipment includes:

- Hard hats-protect from falling debris.

- Safety gloves-used to prevent cuts and abrasions.

- Steel-toe boots-these are to protect the feet from the heavy loads.

- Fall arrest systems – Securing workers at heights.

Use of proper PPE equipment shall always be emphasised on site.

Safe Work Procedures

Strict safety protocols reduce on-site accidents. Key practices include:

- Following manufacturer guidelines for formwork assembly and removal.

- Avoiding overloading platforms and scaffolding.

- Keeping the site organized to minimize trip hazards.

Regular safety briefings help reinforce these procedures.

Team Coordination

Clear communication between workers and supervisors ensures smooth operations. Best practices:

- Pre-task meetings – Discussing safety concerns before work begins.

- Signaling systems – Using hand signals or radios for clear instructions.

- Emergency planning – Establishing procedures for responding to structural failures.

Effective coordination enhances overall site safety.

Environmental Considerations

Weather-Related Risks

Environmental conditions can compromise formwork stability. Factors to consider:

- Wind loads – Strong winds may cause displacement.

- Rain and humidity – Excess moisture weakens materials and makes surfaces slippery.

- Temperature changes – Extreme cold or heat affects concrete setting and material strength.

Work schedules should be adjusted based on weather forecasts to minimize risks.

Sustainable Formwork Practices

Eco-friendly alternatives improve efficiency and reduce waste. Strategies include:

- Reusable plastic formwork – Durable and cost-effective.

- Optimized material usage – Reducing excess waste.

- Recycling old formwork components – Minimizing environmental impact.

Sustainable solutions contribute to safer and more efficient construction practices.

Regulatory Compliance

Safety Standards

Organizations like OSHA establish guidelines for formwork safety. Key requirements include:

- Proper load calculations to prevent overloading.

- Secure bracing and shoring to support structural stability.

- Worker protection measures such as fall prevention systems.

Following these regulations ensures compliance and prevents legal liabilities.

Local Construction Codes

Each region has specific building regulations regarding formwork. Adherence to these codes ensures:

- Structural integrity for long-term stability.

- Legal compliance to avoid fines or work stoppages.

- Worker safety through standardized best practices.

Understanding local requirements is crucial for project success.

Cost-Effective Safety Investments

Long-Term Benefits of Safety

Prioritizing safety reduces financial risks by preventing:

- Accident-related expenses such as medical costs and legal fines.

- Project delays due to equipment failure or regulatory violations.

- Material wastage from formwork collapse or rework.

Investing in high-quality safety measures results in cost savings over time.

Reducing Risk Through Planning

Proactive risk management lowers the likelihood of accidents. Best practices include:

- Thorough project planning to identify potential hazards.

- Using certified materials to ensure durability.

- Continuous monitoring to detect early warning signs of failure.

Strategic planning enhances both safety and operational efficiency.

Conclusion

Formwork safety is a critical aspect of concrete construction. By recognizing hazards, enforcing best practices, and complying with regulations, construction teams can create a safer work environment. Investing in quality materials, proper training, and well-planned procedures not only protects workers but also enhances project efficiency and cost-effectiveness. A strong commitment to safety ensures the long-term success of any construction project.

FAQS

What are the common causes of formwork collapses?

- Common causes include inadequate design, improper installation, overloading, and poor-quality materials.

What PPE is required for formwork activities?

- Essential PPE includes helmets, gloves, safety harnesses, and non-slip footwear.

Related Information

Code of Practice: Formwork----SafeWork

Formwork----Wikipedia