Scaffolding fittings are components that join scaffold tubes together. Scaffolding fittings are considered the "working" parts of temporary structures constructed for a particular purpose, whether based around construction, maintenance, repair, or events.

Scaffolding fittings are manufactured from strong materials, commonly galvanized steel or aluminum, so they maintain structural integrity when it is expected to support scaffolders, tools, and materials at heights. It is a flexible building system and detached and creates an infinite number of uses, and it has been designed to accommodate a pocket of outputs, such as simply renovating a home, developing complex temporary structures for heavy infrastructure building developments, or an outdoor event.

Appreciating the type of application can have a huge impact on project efficiency and worker safety (this is on everybody's mind). Recognising what each fit-out is and the intended use and limits would ensure you safely limit confusion and misunderstandings, and industry regulations compliance.

Scaffolding Couplers Types

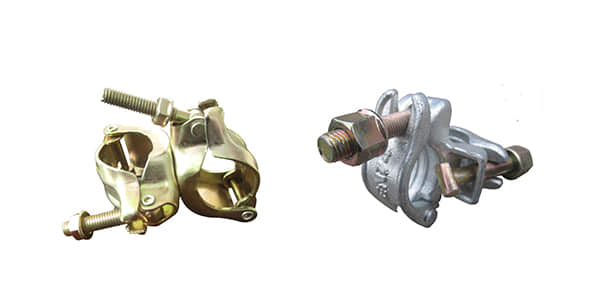

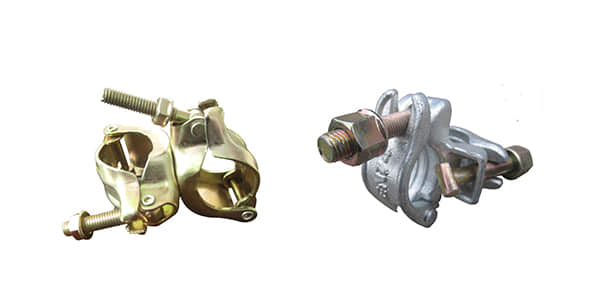

Swivel couplers join two scaffold tubes with the same compression function as other coupler types, but with the added ability to connect two tubes at any angle. Because of the ability to hook up directly to a diagonal or unconventional connection to the braced structure, swivel couplings are used in almost all scaffolding situations because swivel couplings can provide secured overall stability to an entire structure. Swivel couplings are usually used as a component of a bracing system.

- Design: Swivel coupler designed with a pivoting point so that connections can turn on a full 360-degree axis.

- Applications: typical on diagonal bracing, or curved scaffold structures, and non-standard scaffold layout.

- Benefits: flexibility in design with any project variability.

Right-angle couplers, also called double couplers, connect two tubes at a defined 90-degree right angle with a high load capacity, which is why they are a staple of standard scaffolding grids.

- Design: Two fixed clamps allow for perpendicular connections.

- Application: To connect horizontal ledgers to vertical standards in rectangular structures.

- Advantages: High levels of strength and stability for heavy structures.

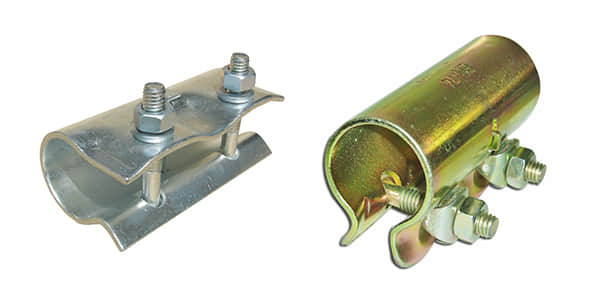

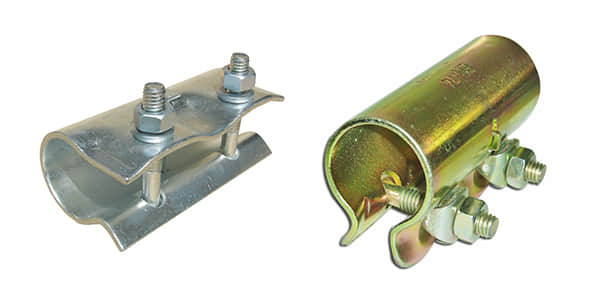

Sleeve couplers connect two tubes from end to end and will essentially extend the length of a tube. They are a must-have when making long runs in large-scaffolding systems.

- Design: A tubular sleeve that is fitted over the ends of the tube and fastened with bolts.

- Uses: Extending horizontal or vertical tubes in large-scale scaffolding

- Benefits: Adding length without loss of strength!

Putlog couplers are used to connect putlog tubes (horizontal supports) to ledger tubes for placing scaffold boards. Putlog couplers are essential when forming a secure working platform.

- Design: A single clamp that clamps the putlog tube to the ledger.

- Uses: To secure scaffold boards to the main structure.

- Advantages: Makes platform assembly easier for safe worker usage.

5. Beam Couplers

Beam couplers are used to secure scaffold tubes in place on steel beams, joining scaffolding to existing elements. Beam couplers are commonly used within industrial and infrastructure operations.

- Design: A clamp that secures both a tube and a flange of a beam.

- Application: Joining scaffolds onto steel structures (e.g., bridges or factories).

- Benefits: Secure anchorage to non-tubular structures.

6. The Role of Board Retaining Couplers

Board retaining couplers lock scaffold boards in place, limiting slippage or movement of boards, which is essential for safer platforms.

- Design: It is a clamp that 'locks on' to the board so it does not move and is secure to the scaffold frame.

- Use: Stability of working platforms in high traffic areas.

- Benefits: Reducing the risk of boards moving is an additional layer of safety.

7. Joint Pin Couplers

Joint pin couplers create two tubes that are connected internally together end-to-end. They hold the tubing in a straight alignment with no external features to interfere with the overall design. They are used primarily when the connecting area is restricted in space or some other aesthetic-related concern.

- Design: An internal pin that fits inside the tube end (both ends) using a locking mechanism to secure the connection.

- Use: To create flush connections when little space is present.

- Advantages: Clean and unobtrusive joints create a simple and clean design solution.

8. Half Couplers

Half couplers are a type of coupling that fix one tube to a position (i.e., to a wall or to a column), which provides a secure attachment point for the free end of the scaffold.

- Design: A single clamp that has a base so it can attach firmly to a surface.

- Applications: Connections of scaffolding to buildings or similar elements.

- Functions: secure attachment to na on-scaffold structure.

9. Limpet Couplers

Limpet couplers are made of light materials and are intended for low-load applications, such as securing scaffold boards or temporary barriers.

- Design: A small clamp with a straightforward and simple locking mechanism.

- Applications: Intended for temporary or light scaffolding setups in width.

- Advantages: very easy to use, inexpensive given the size of typical projects.

10. Ladder Couplers

A ladder coupler is used to attach a ladder to a scaffold structure to ensure a means of safe and stable access for workers.

- Design: A clamp that connects ladder rungs to scaffold tubes.

- Applications: To attach ladders for vertical access.

- Benefits: Allows for better mobility and safety for workers.

11. Fencing Couplers

Fencing couplers let you attach mesh, netting, or barriers to scaffold tubes for protective barriers or debris shields.

- Design: Clamp has flexible components, such as netting.

- Applications: Installing safety barriers or debris protection.

- Benefits: Provides containment and therefore increases site safety.

Applications of Scaffolding Couplers

- Construction: Assist with the erection of buildings, bridges, and skyscrapers using right-angle couplers and swivel couplers.

- Maintenance: Use half couplers to stabilize cleaning, painting, or maintenance on a high-rise.

- Events: Use limpet and fencing couplers to create temporary stages, seating, or lighting for events and concerts.

- Shipbuilding/Offshore: Provide stable platforms using Beam couplers in a shipyard or offshore situation.

- Industrial: Use sleeve and joint pin couplers in factory or power plant maintenance.

Safety Considerations for Scaffolding Couplers

- Inspections: Inspect the connectors for signs of wear, corrosion, or damage before every use and replace any faulty parts.

- Certified Components: Use connectors that meet standards such as EN74 or BS1139.

- Installation: Tighten to the manufacturer's specifications for torque and not more or less than those specifications.

- Load Limits: Respect the load limits of the connector to not creating a failure.

- Training: Train all workers who will be assembling and managing safety on the site.

- Environmental Factors: Consider any forms of environmental consideration, such as wind, rain, or vibrations. Swivel connectors are especially important in bracing to create stability.

- Monitoring: Identify the risk of connectors loosening or fatigue while the project is ongoing. Regular site inspections.

Maintaining Scaffolding Couplers

- Cleaning: Remove dirt or debris with a wire brush or pressure washer.

- Storage: Keep in dry, ventilated areas. Apply protective coatings for steel couplers.

- Lubrication: Lubricate moving parts, like swivel coupler pivots, to prevent seizing.

- Nspections: Check for wear or damage before and after use, especially load-bearing couplers.

- Repairs: Treat minor rust with anti-corrosion sprays; replace severely damaged couplers.

- Guidelines: Follow the manufacturer’s maintenance instructions for specific types.

- Inventory: Organize couplers by type and condition for efficient inspections.

Choosing Scaffolding Couplers

- Project Scope: Use robust couplers (e.g., right-angle, sleeve) for large projects; lighter ones (e.g., limpet) for temporary setups.

- Environment: Choose corrosion-resistant materials (galvanized steel, aluminum) for humid or coastal areas.

- Load Needs: Opt for high-capacity couplers for heavy-duty projects.

- Compliance: Ensure couplers meet local standards (e.g., OSHA, EN74) for safety and legality.

Conclusion

Scaffolding couplers are the unsung heroes of safe and efficient construction, maintenance, and industrial projects. From the flexible swivel coupler to the sturdy right-angle coupler, each type plays a vital role in creating reliable scaffolding systems. By understanding their applications, prioritizing safety, and committing to regular maintenance, you can maximize their performance and ensure worker safety.

Whether you’re a contractor, project manager, or safety officer, this guide equips you with the knowledge to make informed decisions about these critical components.

FAQ

Are scaffolding couplers compatible with all scaffold tubes?

- Most couplers are designed for standard tube sizes (e.g., 48.3mm diameter). Always check specifications for compatibility with your scaffolding system.

Can scaffolding coupler types affect project safety?

- Yes, using the correct coupler type ensures structural stability. Always follow manufacturer guidelines and industry standards (e.g., EN74 or OSHA).

Read More

Seven Fundamental Parts of a Scaffold— Avontus

Scaffolding Parts Explained— Humanfocus