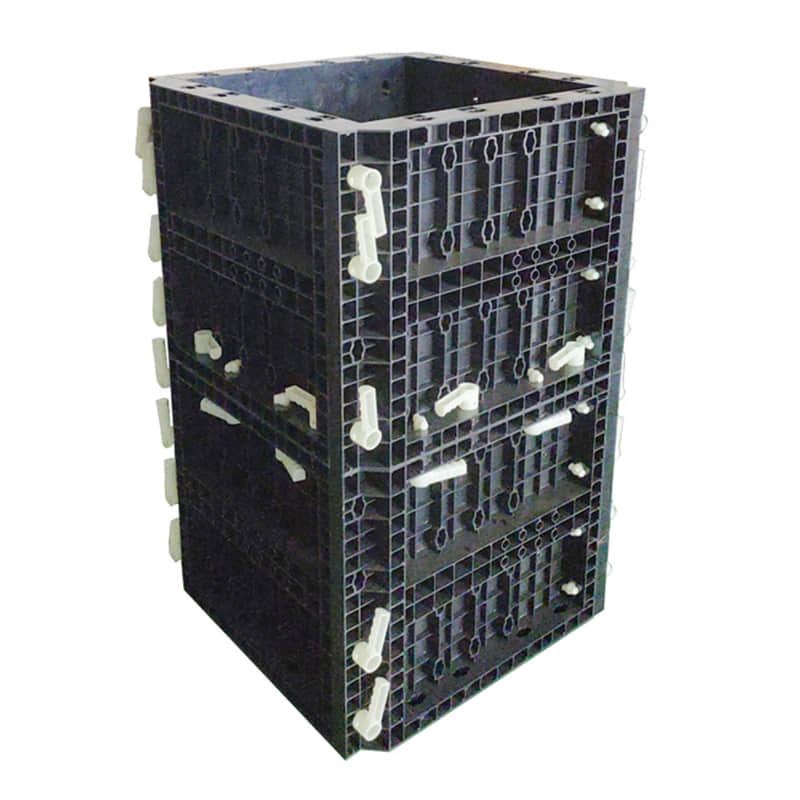

Plastic Outer Corner Formwork (also known as external corners) are components manufactured with a vertical side for forming concrete columns, beams, and walls. This component comes in the form of a pre-molded L-shaped piece which can be used for 90-degree corners.

Instead of creating corners by nailing two flat sheets together like plywood, plastic systems construct corners using a rigid, pre-manufactured corner piece. This guarantees that the building will be square and leak-free when the plastic system is used.

Our plastic outer corner forms have been developed as an alternative to traditional plywood or heavy steel corner forms, and they provide a lightweight, high-strength way to connect wall and column forms together. Our products are perfect for use in civil engineering, commercial building, and infrastructure, and they help create a smooth finish and reduce costs significantly due to their very high levels of reuse

Why Choose Our Plastic Formwork? (Key Features)

- Superior Durability (High ROI): Compared to plywood products, our plastic corners can be reused 50-80 times with proper care and maintenance, making them a solid choice for scaffolding or formwork rental businesses interested in extending their asset life.

- Waterproof & Weather Resistant: Our corners are made from a custom-engineered Polypropylene/ABS composite that is not affected by moisture, rain or rotting. Therefore, they will maintain their original dimensions even under the harshest tropical/humid conditions.

- No Release Agent Required: The smooth surfaces of the corners make it easy to strip the corners from the plaster without the need for chemical release agents. This saves labor and material costs, and gives the concrete a "fair-faced" finish with very little plastering necessary.

- Lightweight & Easy Handling: These corners are much lighter than steel, so they can be installed and removed quickly without the use of large cranes. This increases safety and efficiency at the job site.

Key Specifications

|

Specification |

Details |

|

Material |

High-Impact Polypropylene (PP) / ABS Composite |

|

Standard Lengths |

200mm, 250mm, 600mm (Customizable up to 3000mm) |

|

Width |

100mm |

|

Thickness |

50mm |

|

Temperature Range |

-20°C to +70°C |

|

Color |

Black / Grey / White (Customizable) |

|

Certification |

ISO 9001, SGS Test Reports Available |

Advantages Over Timber/Steel

|

Feature |

Plastic Outer Corner |

Timber/Plywood Corner |

|

Leakage |

Zero leakage: Molded as one solid piece, so grout cannot escape the corner seam. |

High risk: Grout often leaks where two boards meet, causing "honeycombing." |

|

Precision |

Fixed 90°: Cannot be assembled "out of square." |

Variable: Depends on the carpenter's skill to nail it square. |

|

Durability |

Reusable: Can be used 50–100 times. |

Low: Edges fray and rot after a few uses. |

Applications

Concrete Columns: Creating perfect 90-degree external corners for square and rectangular columns.

Wall Junctions: Seamlessly connecting flat formwork panels at outer edges.

Infrastructure: Bridges, tunnels, and government public utility projects.

en

en fr

fr es

es