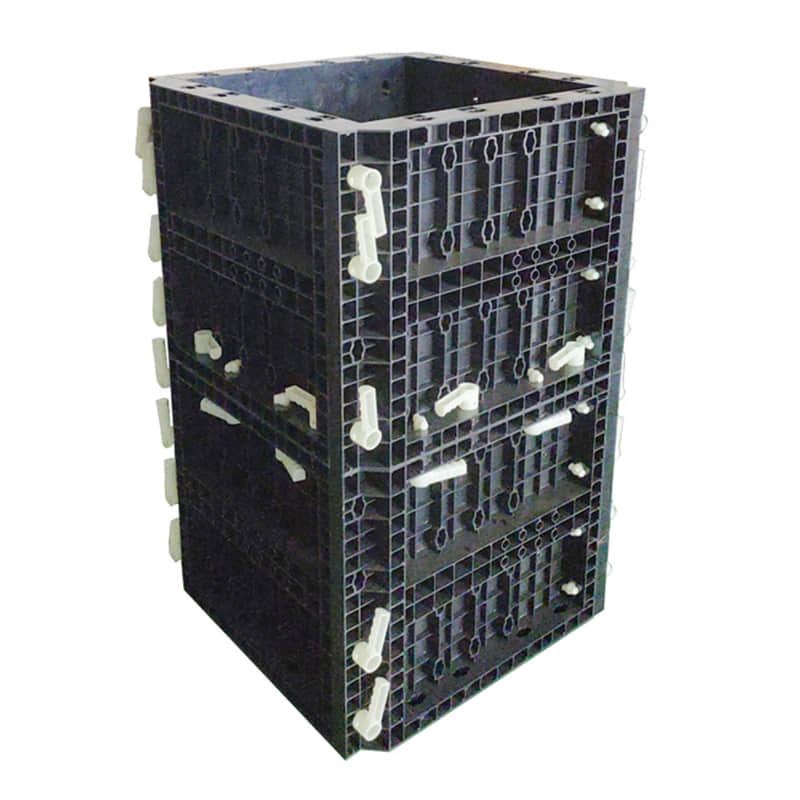

Plastic Inner Corner formwork is a module specifically designed for plastic formwork systems to create 90-degree (90°) internal angles. A Plastic Inner Corner Formwork eliminates the need for timber at the corners of your concrete walls, columns, and foundations by forming the pre-molded, ready-to-install L-shaped pieces from the manufacturer and locking into straight-sided panels of the formwork system.

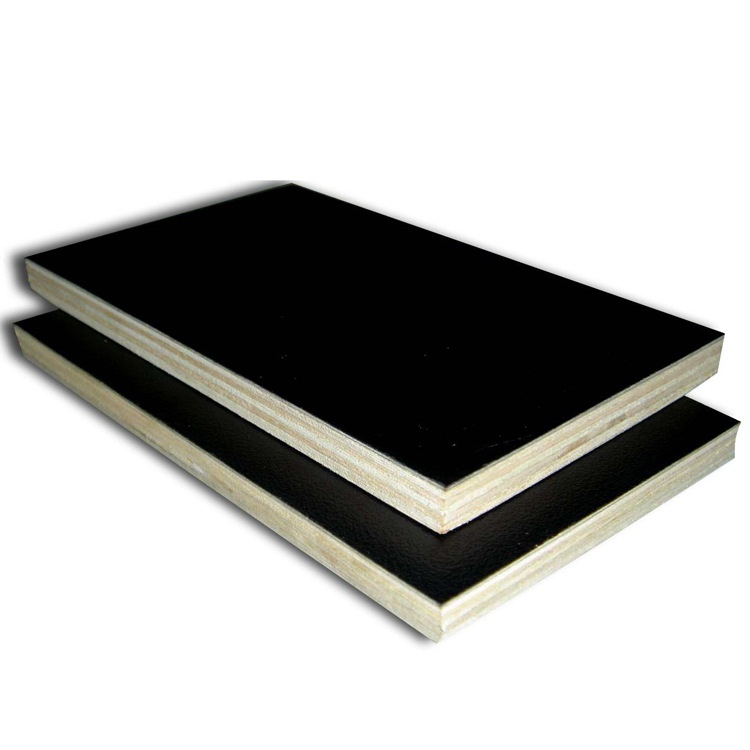

Achieve Perfect 90° Angles with Superior Durability. Designed for modern construction projects, our Plastic Inner Corner Formwork replaces traditional plywood and heavy steel corners. Engineered for high-frequency usage, this lightweight solution helps scaffolding rental companies and construction firms reduce labor costs and maximize material turnover.

Technical Specifications

|

Specification |

Details |

|

Product Name |

Plastic Inner Corner Formwork / Internal Corner Mold |

|

Material |

High-Impact PP/ABS Composite (Industrial Grade) |

|

Standard Size |

200mm x 200mm (Customizable) |

|

Height Options |

200mm / 250mm / 600mm |

|

Temperature Range |

-20°C to +70°C (All-weather performance) |

|

Color |

Black / Grey (Custom colors available for bulk orders) |

Key Functions & Features

- Geometry: This creates the inside corner of a wall as well as the internal angle of a T-junction.

- Modular Connection: Uses standard holes or slots located along the edges to connect to straight panels that utilise nylon locking handles or pins/wedges.

- Material: Can be made of high-strength ABS (Acrylonitrile Butadiene Styrene) or PP (Polypropylene) with glass fibre reinforcement.

- Reusability: Designed for a lifetime of use. Can be reused 100+ times if maintained properly.

Advantages Over Timber/Steel

- No Grout Leakage: Because the molded angle is one continuous piece, there are no seams for concrete to bleed through, a common problem with wooden forms.

- Stripping: Since plastic does not stick to concrete, once the corner has cured sufficiently, it can be easily removed from the plastic with no release agent and without any plastering required for a smooth finish.

- Waterproof: It cannot be ruined (warped/rotten/swelled) by being left outdoors (in rain) nor stored (in damp places).

- Zero Waste: No cutting of plywood is required to form the corner.

Applications

- Ideal for residential buildings, commercial complexes, civil engineering projects, and any concrete structure requiring precise internal corners.

Ready to lower your project budget? [Get a Free Quote Now] or [Request a Free Sample] to test our quality on-site. We support OEM/ODM for global distributors.

en

en fr

fr es

es