How Often Must A Competent Person Inspect the Scaffold

Oct 27, 2023

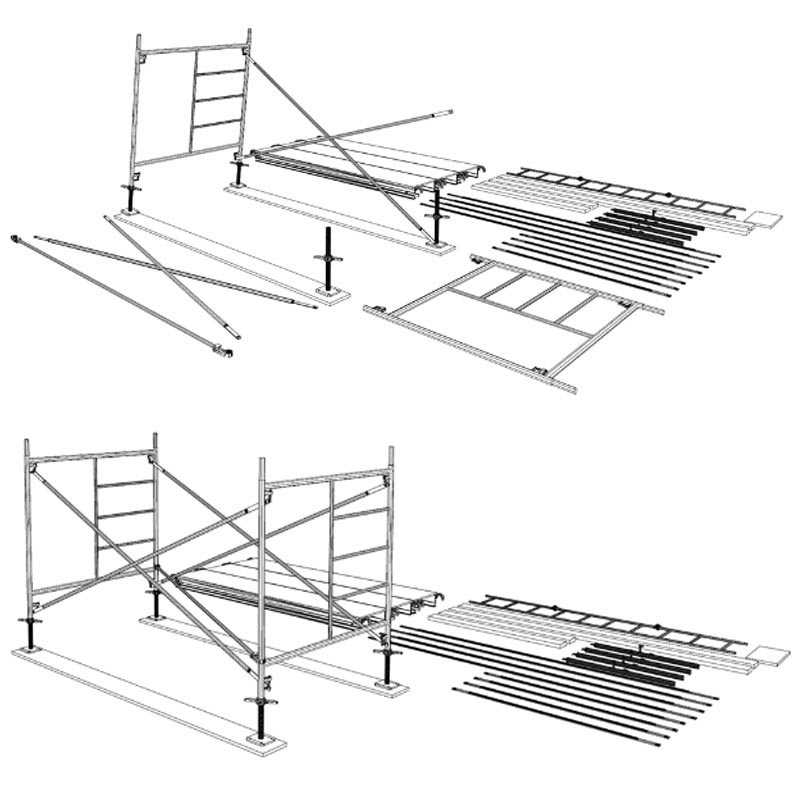

Concrete metal steel scaffolding are indispensable tools in the construction industry, providing access to elevated work areas. Ensuring their safety and structural integrity is paramount. In this article, we'll explore the critical role of competent persons in scaffold inspections and the frequency of these inspections, from the initial assessment to daily checks and periodic evaluations.

Initial Inspection

An initial inspection sets the stage for scaffold safety:

Definition and Purpose: An initial inspection is the first assessment of a scaffold's structure and setup before it's put into service. Its purpose is to confirm that the scaffold is erected properly, in compliance with design specifications, and ready for use.

The Role of a Competent Person: A competent person, typically with expertise in scaffold safety, conducts the initial inspection. They examine various components of the scaffold, including the foundation, supports, platforms, guardrails, and access points.

Key Components to Assess: During the initial inspection, the competent person ensures that the scaffold is stable, level, and capable of safely supporting the intended loads. They also check for any defects, damaged parts, or missing components.

Frequent (Daily) Inspections

Daily inspections are a shared responsibility:

Daily Checks by Scaffold Users: Scaffold users, usually at the start of each work shift or before each use, perform daily inspections. Their role is to check for visible defects, damage, or potential hazards, such as loose connections, debris, or slippery surfaces.

What to Look for During Daily Inspections: Scaffold users should be vigilant for any signs of wear and tear, instability, or unsafe conditions. If any issues are identified, they should be reported to a competent person, supervisor, or safety officer.

Periodic (Regular) Inspections

Competent persons conduct periodic inspections:

Role of Competent Persons in Periodic Inspections: Competent persons, trained and qualified in scaffold safety, are responsible for periodic inspections. The frequency of these inspections can vary, but they are often required on a weekly basis, especially for scaffolds in continuous use.

Comprehensive Assessment Criteria: Periodic inspections involve a more comprehensive assessment of the scaffold's condition, including structural integrity, stability, and compliance with safety standards. Competent persons ensure that the scaffold remains in good condition and within its weight limits.

The Competent Person's Role

Qualifications and Training: A competent person should have the necessary qualifications and training to identify potential hazards and ensure the scaffold's safety. Training and experience are crucial to perform inspections effectively.

Responsibilities and Reporting: Competent persons are responsible for reporting any identified issues and taking appropriate actions to address them. This includes recommending repairs, modifications, or even taking the scaffold out of service if necessary.

Scaffolding Inspection Content

Foundation and support:

Confirm that the scaffold foundation is in good condition and is neither sunken nor loosely connected.

Inspect whether the bracketing is installed appropriately, and whether the correct foundation beams and plates are used.

Structural stability:

Verify that the general structure of the scaffold is safe and all connections and joints are secure and intact.

Inspect the vertical and horizontal stability of the scaffolding, whether it tilts in an unintended direction, and deformation.

Material quality:

Determine whether the scaffold material meets the standard and has not corroded, been damaged, or deformed.

Inspect the scaffolding pipes, fixings and other components to check whether they are broken, bent or otherwise impaired.

Safety provisions:

Checking if there are safety measures in place, such as the installation of essential safety features e.g. safety netting and guardrails.

Checking the board of the scaffold footing, checking the board is secure and laid level and if the non-slip surface is applied.

Load Capacity:

Checking that the scaffold design and erection is in accordance with load requirements and not overloaded.

Inspecting whether materials or equipment are loaded onto the scaffold that the loading has been allowed for in the scaffold design.

Walkways & access and egress:

Check if there are clear and safe walkways and access and egress areas on the scaffold and that these comply with the regulations in place.

Checking that the walkways and access and egress areas have non-slip surfaces and are clear.

Electrical services:

Checking whether there are wires and cabling near the scaffold and if they are protected correctly.

Checking the scaffold that electrical equipment is installed and if it complies with safety requirements and that wires are not exposed or damaged.

Scaffolding Inspection Report Contents

Project Particulars:

Name of Project and Project Number

Date and Time of Inspection

Inspector’s Name and Position

Inspection Items and Results

Explain each inspection item and note down the result of the inspection.

Detail the problems and unsafe hidden dangers discovered, stating the specific location and situation.

Corrective Actions:

List rectification recommendations and actions for the identified problems.

Record and specific manner in which the rectification actions will be implemented and the person responsible for the actions.

Acceptance Status:

State the status correct and re-inspect to confirm the problem has been solved.

Acceptance personnel sign and verify, documenting acceptance date and time.

Additional Information:

Photos and video from the inspection are attached to make the inspection easily comprehensible to the visual audience.

Any other situations needing clarification and considerations need to be provided or addressed.

Challenges and Common Issues

Addressing obstacles to effective inspections:

Obstacles to Effective Inspections: Various challenges, such as time constraints, lack of training, and insufficient resources, can hinder effective scaffold inspections. Addressing these challenges is crucial for maintaining safety.

Addressing Identified Issues: Once issues are identified during inspections, timely action is necessary. Repairing, modifying, or replacing components as needed ensures the scaffold remains safe for use.

Conclusion

Competent scaffold inspections, whether initial, daily, or periodic, play a pivotal role in ensuring workplace safety. The frequency of inspections depends on the type of inspection and the scaffold's use. A competent person's expertise, coupled with compliance with regulations and documentation, fosters a safe working environment where the integrity of scaffolds is preserved.

Read More

Scaffolding Safety Checklist -- SUPREMEPIPE

Guide to Scaffold Inspection and Maintenance -- SAFEWORKAUSTRALIA

Safety Moment | Scaffold Inspection -- YOUTUBE

FAQ

What Is A Scaffolding Inspector?

Responsible for ensuring that all scaffolding in the construction project complies with prevailing standards, procedures, and laws. Monitor the design and certification of all scaffolding structures on site to meet all relevant specifications and standards.

Why Do We Need To Inspect Scaffolding?

Scaffolds can collapse due to overloading or instability. Therefore, it is crucial to regularly inspect scaffolds to prevent potential hazards from leading to accidents.

What Is Scaffolding In Hse?

At its most basic, a scaffold is any temporary elevated or suspended work platform used to support workers and/or materials.