Looking for reliable, durable scaffolding components to keep your project running smoothly? Our premium Cuplock Scaffolding Components are made to outperform the ever-increasing demand of today's construction and engineering projects. We offer a full range of components with an expected layout and specification that provides a complete, efficient, and safe solution for your build.

Our Product Advantages:

- Excellent load-bearing capacity and stability: Made of high-quality Q235 or Q345 steel and precision welding technology, it ensures that each component can withstand tremendous pressure and provide rock-solid support for your building structure.

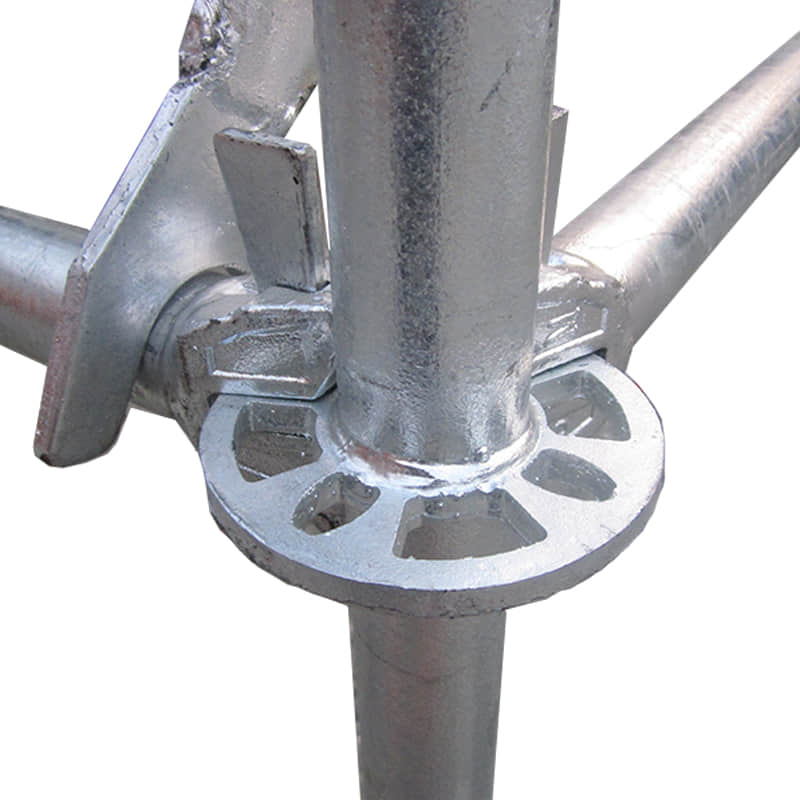

- Efficient and fast installation: The unique disc-type connection design does not require bolts and nuts. A single worker can complete assembly and disassembly in a short time, greatly saving manpower and time costs.

- Durable and corrosion-resistant: All components are hot-dip galvanized to effectively resist harsh weather and environmental erosion, extending product life and saving you long-term maintenance costs.

- Wide range of applications and flexibility: Our cuplock system can be flexibly applied to various complex building structures, whether it is high-rise buildings, bridges, tunnels, or industrial plants, it can be perfectly adapted.

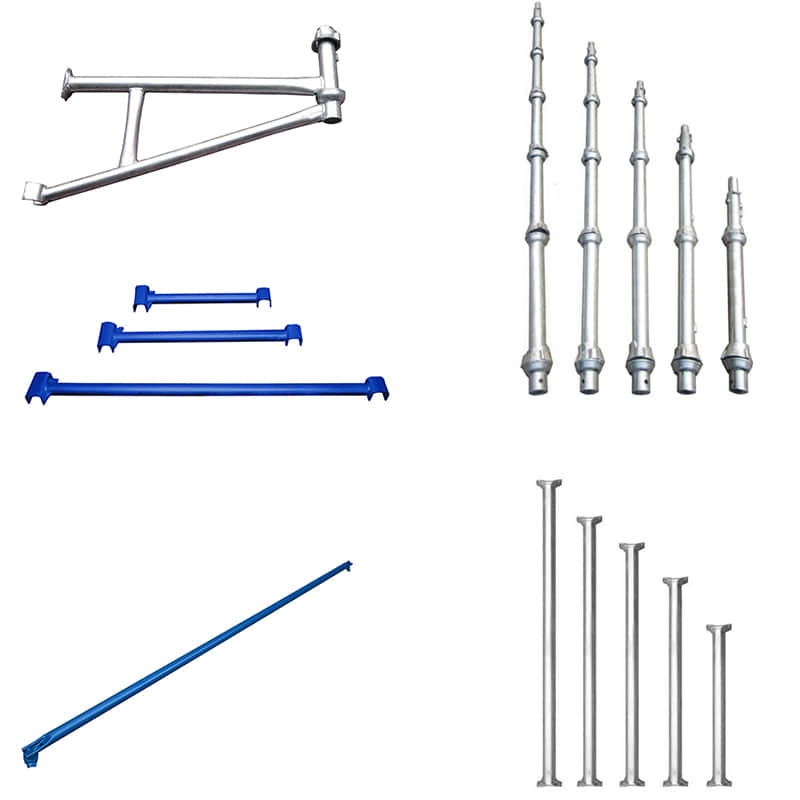

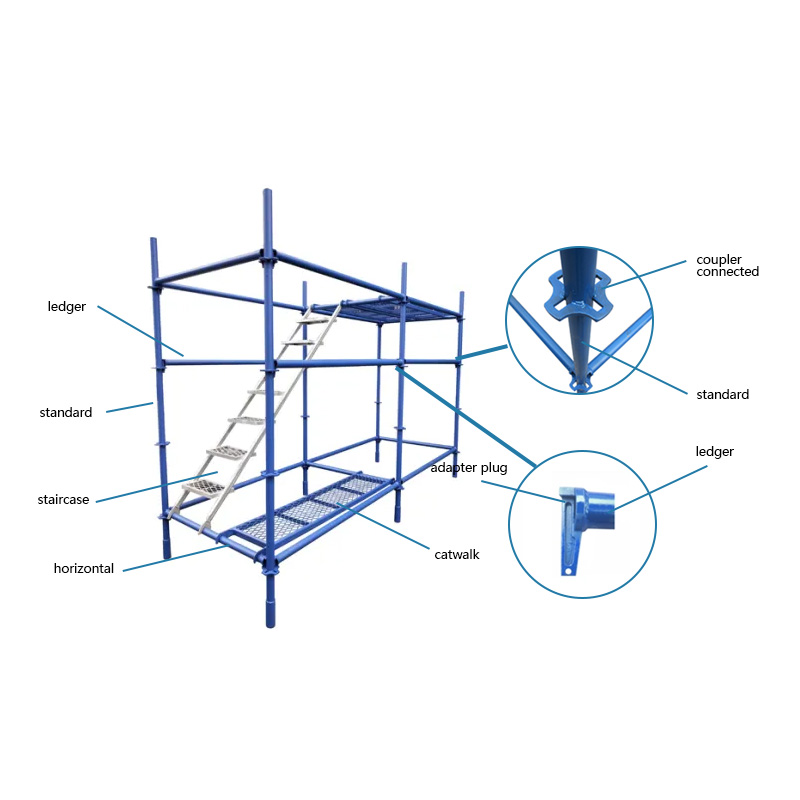

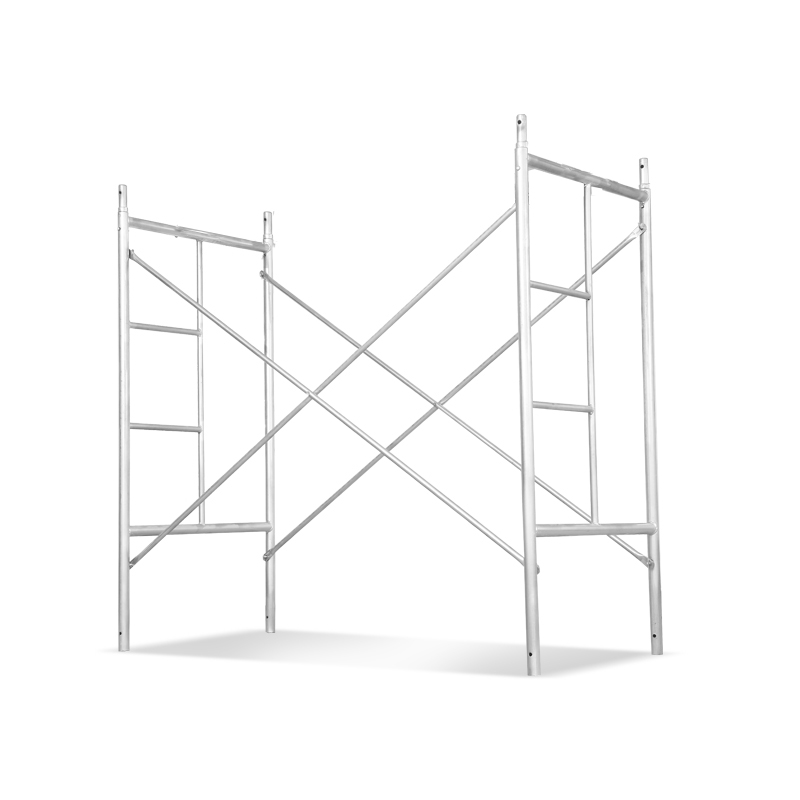

Cuplock Scaffolding Components/Accessories

Our cuplock scaffolding system consists of the following main components. All components are manufactured according to the highest standards in the industry, and all components can offer a selection of common specifications, as needed for different project requirements.

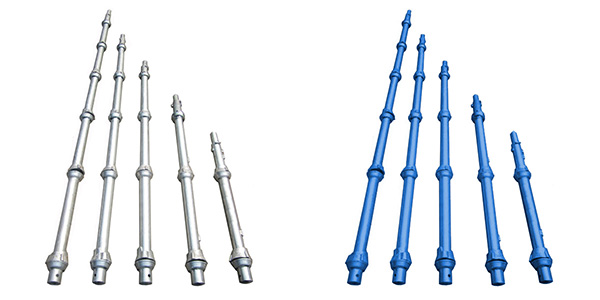

The vertical posts serve as the vertical support of the system. The vertical/standards provide the structural support for the scaffolding system.

- Specifications: Common lengths are: 0.5m, 1m, 1.5m, 2m, 2.5m, 3m.

- Features: Buckle bowls are welded every 50cm or 100cm to facilitate the quick connection of cross bars and diagonal rods.

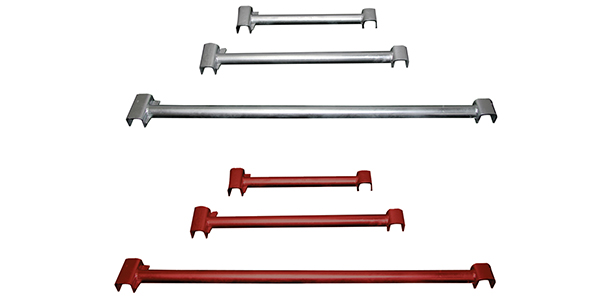

Used mainly to connect the vertical poles to provide the horizontal frame of the scaffolding.

- Specifications: Common lengths are: 0.6m, 0.9m, 1.2m, 1.5m, 1.8m, 2.4m.

- Features: Plugs are welded on both ends and can be quickly inserted into the buckle bowl of the pole without any tools.

Used to increase the overall stability and rigidity of scaffolding, preventing lateral movement.

- Specifications: The length of the crossbar can be customized, and a variety of sizes are available to match crossbars of different spans.

- Features: There are plugs at both ends, which can be connected obliquely to the buckle bowl of the vertical pole.

Used to provide an extended working platform on the outside of the scaffolding.

- Specifications: Common sizes include 0.38m, 0.76m, etc., which can be selected according to project requirements.

- Features: Installed on the vertical pole buckle bowl, providing workers with a more spacious working space.

Used to support the steel gangplank and provide additional horizontal support for the scaffolding.

- Specifications: Length matches the crossbar specifications.

- Features: Usually used to build a steel springboard between two main crossbars to increase the stability of the platform.

Provides workers with a safe way to go up and down the scaffolding.

- Specifications: Length is usually 2m, 3m, or can be customized.

- Features: Lightweight and easy to install, ensuring safe and convenient movement of construction workers between different floors.

Provide initial support and height adjustment for the scaffold.

- Specifications: Common adjustment ranges are 450mm, 600mm, etc.

- Features: Rotatable to adjust height to adapt to uneven ground.

Located at the top of the scaffolding, used to support beams or formwork.

- Specifications: Common adjustment ranges are 450mm, 600mm, etc.

- Features: The U-shaped top design can firmly support wooden beams or steel beams.

Provide a safe working platform.

- Specifications: Common widths are 240mm and 320mm, and lengths can be customized.

- Features: Anti-slip hole design on the surface ensures workers' walking safety.

en

en fr

fr es

es