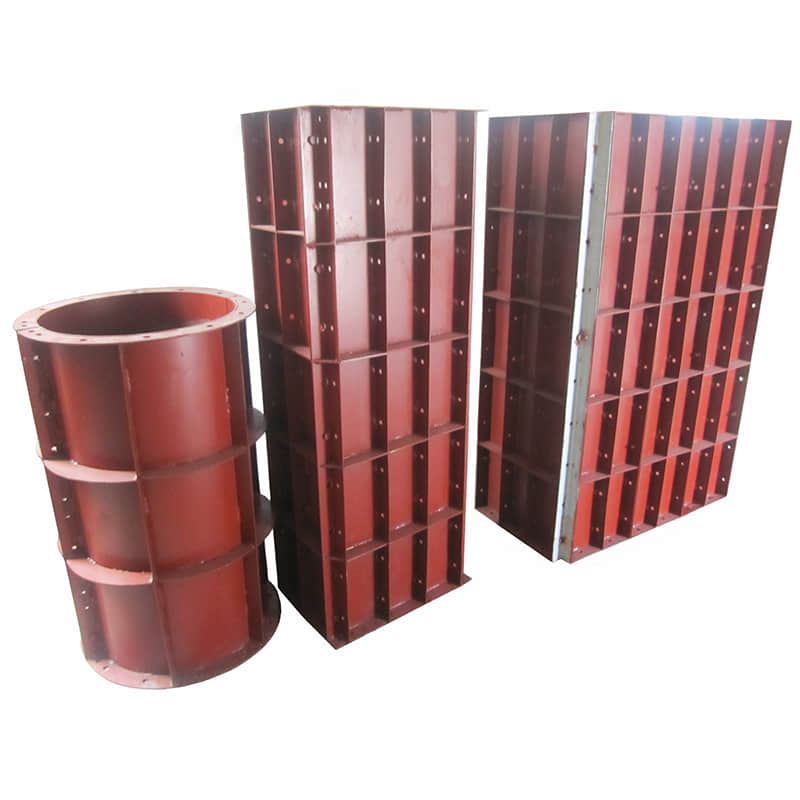

Steel formwork for a concrete slab is a temporary, prefabricated metal mold system that is used to support and shape the wet concrete until it hardens and strengthens. It has the durability and reusability required for modern construction, making it an appealing and popular option for large complex construction projects involving high-rise buildings and infrastructure.

Our Q235 Steel Slab Formwork System is designed for the rigors of modern-day construction in order to promote efficiency, precision, and longevity. Produced from industry-standard Q235 high-tensile steel and with a professional anti-rust, spray paint application, our steel formwork system provides excellent structural integrity for a long lifespan in tough site conditions.

Key Advantages of Steel Formwork

Steel formwork offers significant benefits, particularly for slab construction:

- Durability and Reusability: Due to the strength of the steel, the materials will often withstand reuses (up to 300 times) and are durable, leading to considerable long-term cost savings while minimizing waste on construction sites.

- High Strength: Steel allows for handling great hydrostatic pressure and weight from large or deep pours, which helps avoid deflection or warping avoids ruining the integrity of built structures.

- Finish: The non-porous and rigid nature of steel allows for a very smooth and uniform finish, often reducing or eliminating the need for further plastering or finishing after the concrete has been poured.

- Dimensional Stability: Unlike wood, steel will not shrink, swell, or warp from moisture fluctuations, and plastic deformation will keep the exact final dimensions in concrete.

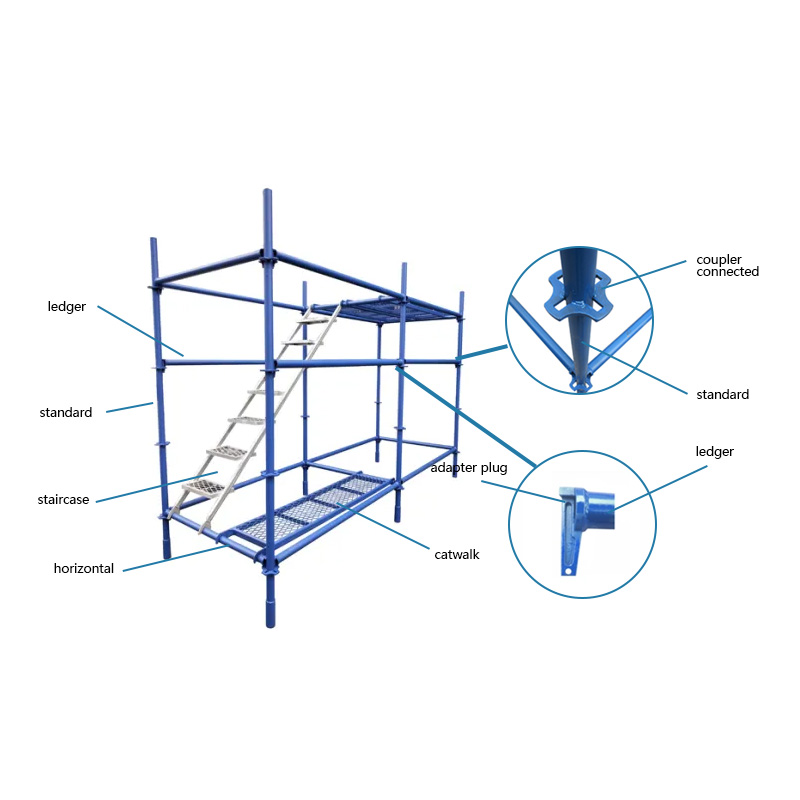

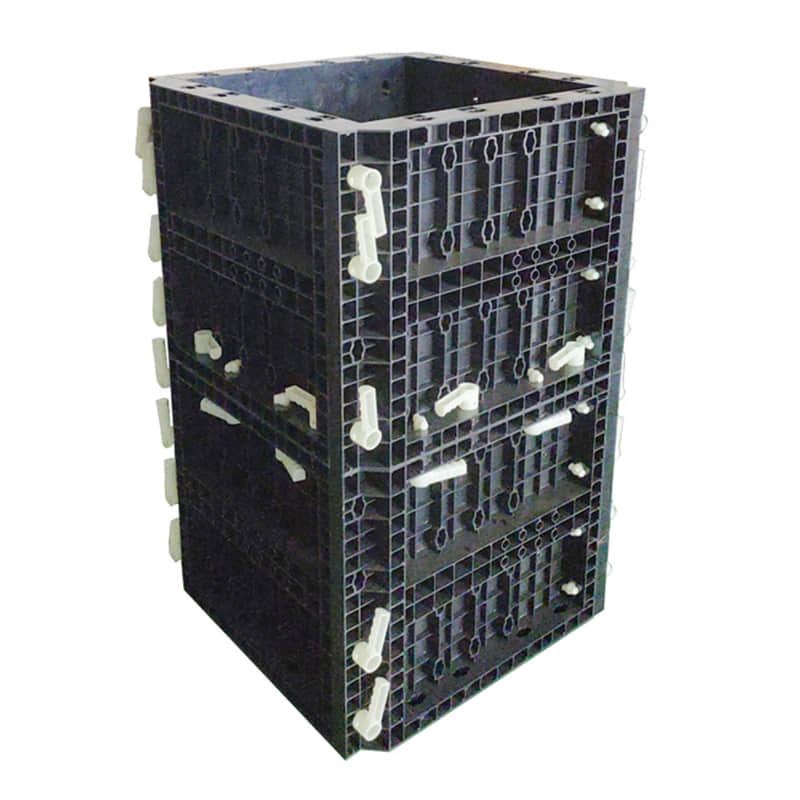

- Efficiency: New formwork systems for steel are generally modular and designed to be quickly assembled and disassembled with locks, bolts, and clamps, all of which can offset some of the construction cycle time.

Detailed Technical Specifications

|

Specification |

Details |

Key Benefit |

|

Material |

Q235 High Strength Steel |

Guarantees structural rigidity and durability of the formwork. |

|

Surface Finish |

Professional Anti-Rust Spray Paint |

Effectively resists moisture and corrosion, extending the panel's lifespan. |

|

Standard Panel Length |

900mm, 1200mm, 1500mm, 1800mm |

Flexible adaptation to various slab area dimensions, minimizing waste. |

|

Standard Panel Width |

200mm, 300mm, 450mm, 500mm, 600mm |

Provides ample combination choices to maximize assembly efficiency. |

|

Frame Height |

55mm |

Enhances overall rigidity to prevent deformation during pouring. |

|

Plate Thickness |

3mm - 5mm (Customizable) |

Solid and durable, greatly increasing the average number of reuses. |

|

Recommended Applications |

Concrete pouring for floor slabs, roof decks, bridge structures, etc. |

Versatile application range, meeting diverse engineering needs. |

en

en fr

fr es

es