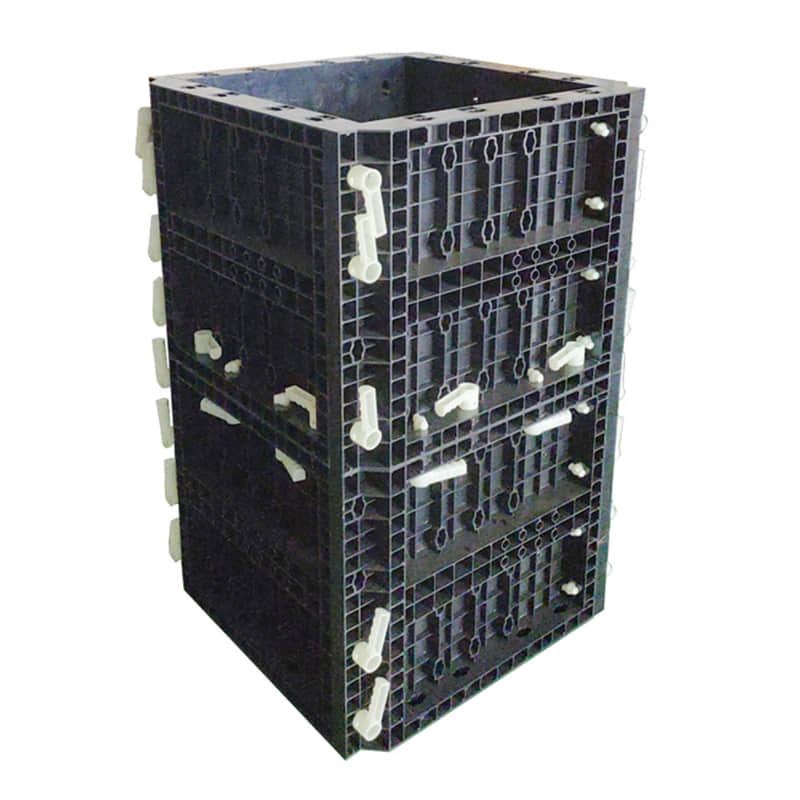

Plastic Formwork is the latest generation of reusable formwork, and it serves as an alternative to traditional wooden or steel forms used to form concrete (e.g., slabs). This modern formwork is quickly gaining popularity because of its strength, light weight, and superior finish.

Our high-strength, reusable plastic formwork for concrete slabs is designed for modern construction, maximizing your construction efficiency and significantly reducing total project costs. Whether for large-scale projects, rental turnover, or material distribution, this lightweight, ultra-durable PP/ABS formwork is ideal for achieving fast, economical, and environmentally friendly construction.

Feature

Plastic formwork systems are typically made from durable plastics like PVC, PP, or ABS, and offer several benefits over conventional materials:

- Reusability and affordability: Although wood has a lifespan of 4 - 10 years, plastic can often be used at least 100 times before it needs replacing. This means you do not need to buy new panels every time you finish a project, and you will save money by using plastic for all of your construction projects.

- Lightweight structure: Typical panels (1200 x 600 mm) can easily be moved by one person without requiring the assistance of a crane for installing floor slabs.

- High compatibility: Wit can be installed, used, and/or removed without needing additional equipment or accessories to interface with any service supporting systems, like metal piping supports.

- Effective demolding: It allows for effective demolding of all forms, as the formwork produces a surface with a V6 grade smoothness that can be directly used as an exposed concrete surface after demolding, thus eliminating the need for a secondary plastering and leveling process, which will save at least 2 hours of labor costs for every square meter of concrete produced using our system.

- Cutability: It can be cut, nailed, and drilled at the construction site easily with standard wood construction tools; thus, it makes working with columns and the irregularities of the edges significantly easier.

Specifications and Dimensions

|

Length(mm) |

Width(mm) |

Thickness(mm) |

|

1200 |

600 | 70 |

|

300 |

600 |

70 |

|

250 |

600 |

70 |

|

200 |

600 | 70 |

|

150 |

600 |

70 |

Why Choose AJ Scaffolding

We stand behind the quality of our goods. Each batch of floor slab plastic formwork is tested extensively for pressure, impact, and aging.

Send an inquiry now! Tell us your project type, required dimensions, and estimated purchase quantity. Our experts will provide you with detailed technical data sheets, customized quotes, and recent success stories within 24 hours!

en

en fr

fr es

es