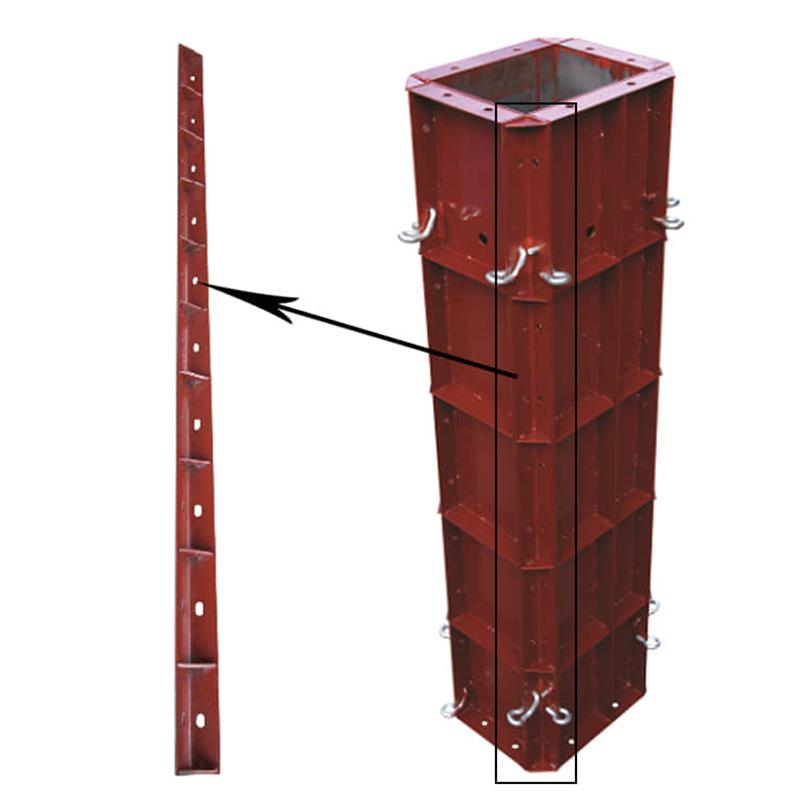

Corner Angles, which can be used to construct outside angles by combining two flat surfaces together at a 90° angle, are made from steel angles that have been bent and shaped into a corner angle.

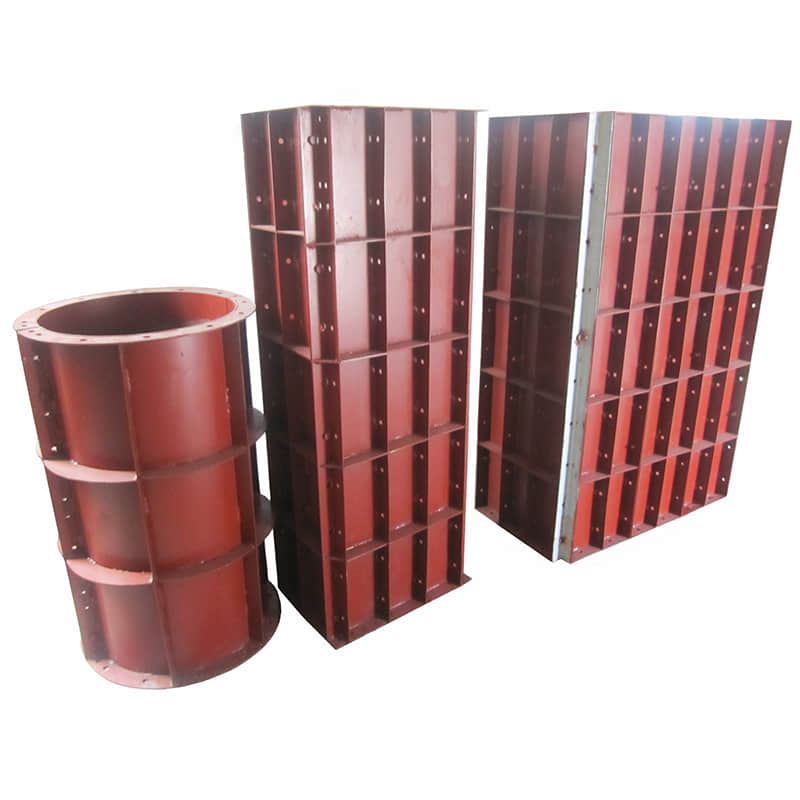

Angle Steel is manufactured with a standard, as well as a customized finish, and can be used for many different purposes. Examples of where you may see Angle Steel used include beam supports, walls, and concrete columns. Additionally, Angle Steel is waterproof and recyclable, making it cost-effective and environmentally friendly.

AJ Scaffolding is a well-known formwork manufacturer in China, providing you with various styles of formwork and accessories, as well as customization services.

Product Specifications

- Material: Q235

- Size: 50*50*600/ 750/900/1200/1500/1800mm

- Thickness: 3mm

Feature

- Steel Corner Angle Formwork can be used as part of a steel formwork system to connect formwork panels and walls in different directions.

- Prevents formwork deformation/cracking;

- Can be easily and securely connected with fasteners;

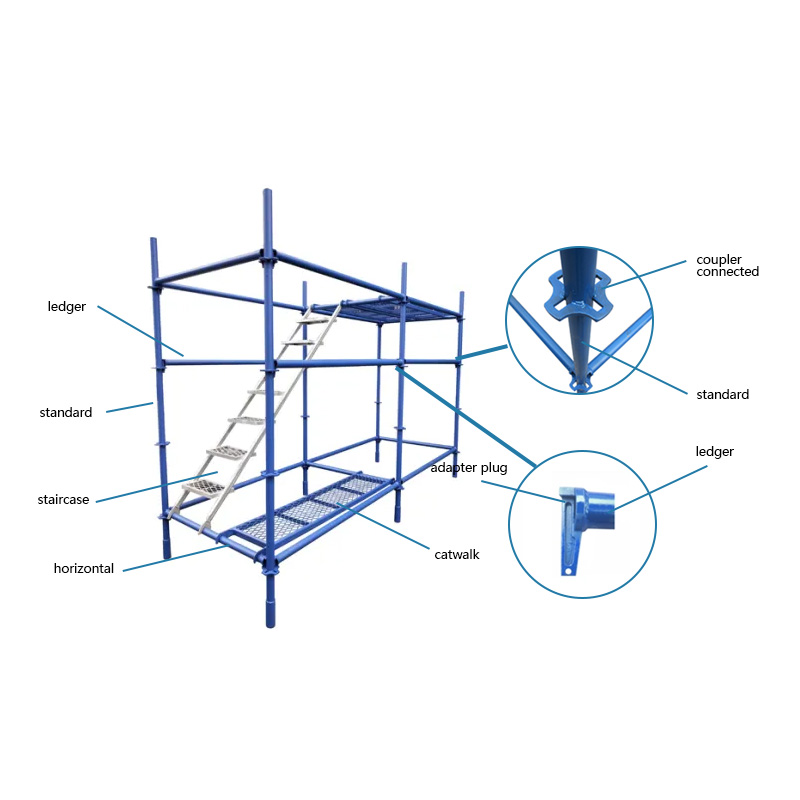

- Widely used in the construction of floor slabs, walls, columns, foundations, and stairs.

Advantages in Construction

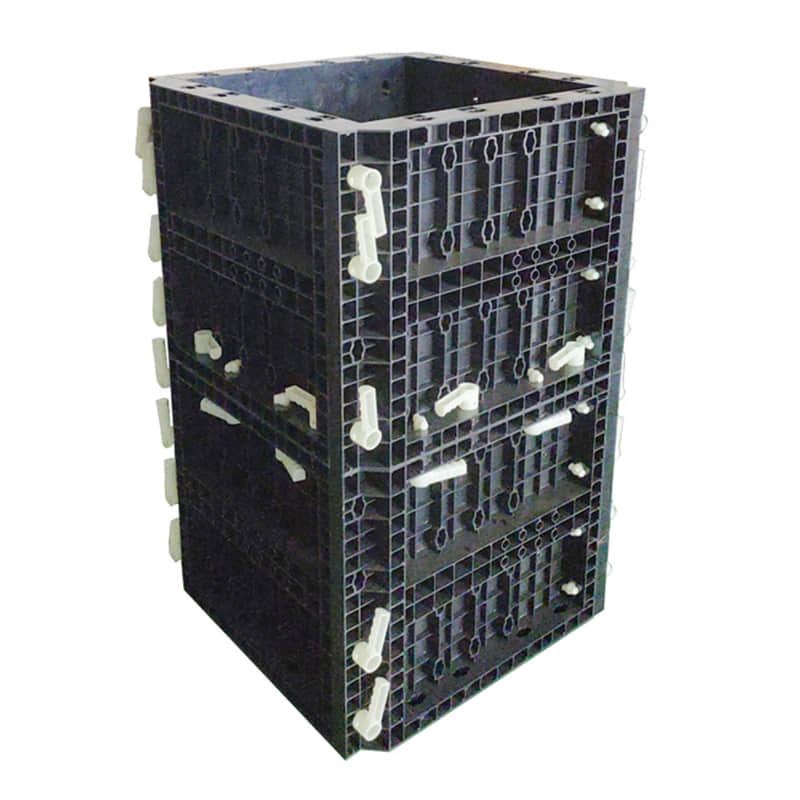

Using steel corner angle formwork offers significant benefits over traditional timber or plywood formwork:

- High Precision and Finish: Because steel has high rigidity and dimensional stability, the corners of finished concrete will be very smooth and sharp, requiring minimal/less or no finishing work.

- Superior Durability and Reusability: Steel can support the high pressures of green concrete without warping or breaking, and can be reused 100 times (timber can be reused 5-10 times). This makes it an extremely cost-effective solution for large or repetitive projects.

- Strength and Stability: The use of the L-shaped design significantly increases the robustness of the entire formwork system and is necessary for preventing the leakage of concrete (seeping) through the joints.

- Non-Absorbent: Wood absorbs moisture from concrete, while steel does not. Therefore, using steel forms allows for proper curing of concrete, which provides the concrete with the strength and integrity it was designed to achieve.

- Faster Assembly/Disassembly: The corner pieces of a modular steel framing system have been pre-engineered; they can easily be locked together, and they are straightforward to assemble and disassemble, thus making it easier to set up and remove the steel forms from the site.

en

en fr

fr es

es