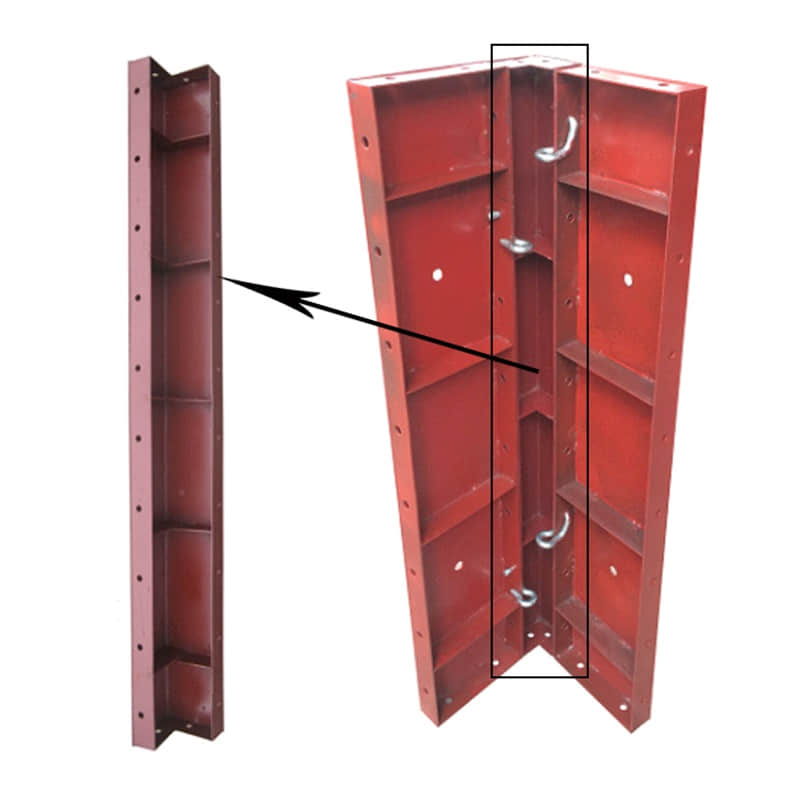

The internal corner formwork is an important component of all steel formwork systems. Interior angular formwork is designed to guarantee that the point where two vertical formwork panels meet is at exactly 90 degrees, as well as to create an excellent, compacted surface for the finished building.

Product Size

- 100*1800*100mm

- 100*1500*100mm

- 100*1200*100mm

- 100*900*100mm

- 100*750*100mm

- 100*600*100mm

- 150*1800*150mm

- 150*1500*150mm

- 150*1200*150mm

- 150*900*150mm

- 150*750*150mm

- 150*600*150mm

Key Features and Dimensions

Standard Inside Corners are designed to be long-lasting and reusable – typically they will:

- Fixed 90° Angle: Designed using a reinforcing strap at each corner to ensure that the right angle remains at a perfect 90 degrees, so that the finished concrete surface is square and uniform.

- Face Dimensions: The most commonly used face dimensions are 4 inches x 4 inches or 6 inches x 6 inches (approximately 100 mm x 100 mm or 150 mm x 150 mm). The choice of face dimension varies based on the particular formwork system, i.e., the thickness of the wall being formed.

- Connecting Slots/Dadoes: Dadoes are the openings in the panel so that Tie Rods can attach to them; slots are the connection points for the hardware to connect the base supports to the forms, which generally occur 12" O.C. and are where wedge bolts are driven through to hold the corner(s) of the forms to the adjoining form panels, and where

- Material: They are constructed from durable, high-quality all-steel for maximum longevity and high load-bearing capacity.

Installation and Locking Mechanism

Placement: The Steel Inside Corner should be positioned vertically at the juncture of two walls.

- Mating: The two perpendicular form panels' steel side rails should be butted together, snugly against both the vertical face of the Steel Inside Corner and the horizontal face of the Steel Inside Corner.

- Locking: Insert a Wedge Bolt through the slots on the side rail of the form panel and into the corresponding slot on the inside corner. When the wedge is driven down, it creates a tight, frictional lock.

- Tying: Insert the tie end (loop or head) into the dado slot on the corner and secure it using a Wedge Bolt or specialized tie hardware. The ties are crucial for resisting the concrete's outward pressure.

Why Choose Our Internal Corner Formwork?

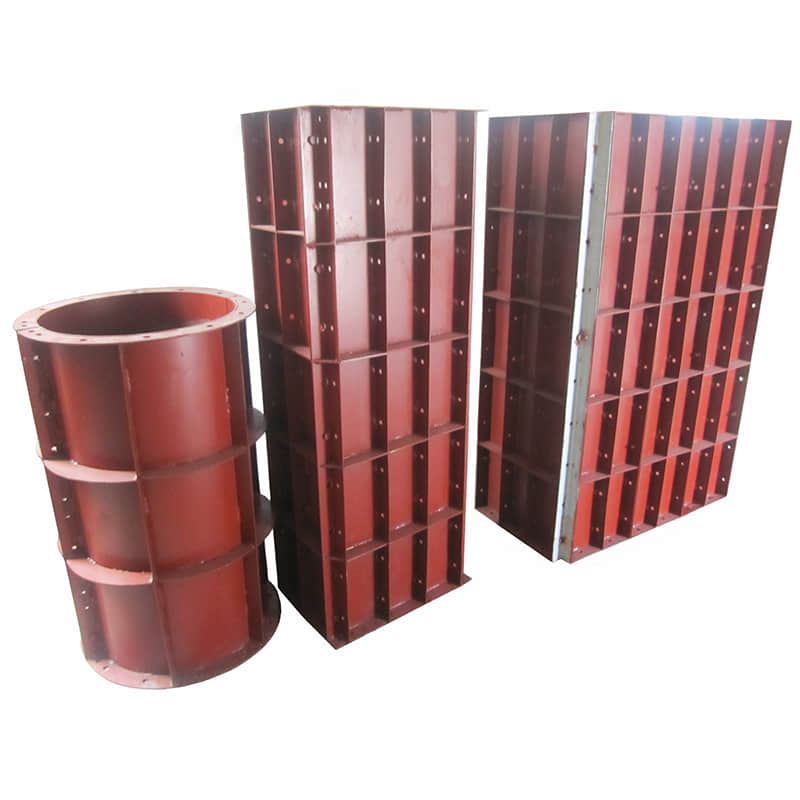

Our heavy-duty steel internal corner formwork is ideal for providing precision, efficiency, and durability in modern concrete construction. Designed specifically for creating perfect 90-degree internal corners, it is suitable for various wall and core tube structures.

- High-Precision Forming: Ensures flat, vertical concrete corners, eliminating the need for secondary repairs and saving time and labor costs.

- Superior Durability: Constructed from high-strength Q235/Q345 structural steel with rust-resistant finishes (such as paint or hot-dip galvanizing), it can be reused up to 300 times, significantly reducing the amortized cost of projects.

- High Compatibility: With a modular design, heavy-duty corner formwork is easily integrated into today’s standard steel, aluminum, and wood formwork systems, giving greater flexibility in on-site construction.

en

en fr

fr es

es