The Ultimate Guide to Scaffolding Base Plate Size

Mar 21, 2025

Safety and stability are the most important factors regarding scaffolding. Every piece is important, but one of the most critical pieces is the scaffold base plate. Sometimes forgotten, the base plate is the base on which your scaffold rests and becomes a base for your overall safety. In this article, we will examine everything you want to know about scaffolding base plates, including plate size, importance, construction type, and how to properly select scaffolding base plates for your project.

What is a Scaffold Base Plate?

The base plate of a scaffold is flat and load-bearing, which is placed at the bottom of scaffold standards (vertical tubes). It helps to distribute the weight of the scaffold and its load evenly on the ground, preventing the scaffold from sinking, tilting, or collapsing. The base plate in scaffolding is a must, whether you’re working on a small construction site or a busy industrial site, to ensure safety and stability.

Importance of Scaffold Base Plate Size

The size of your scaffold's base plate has a direct influence on the safety and stability of your scaffold. Base plates are scaffolded in the proper size:

Even Weight Distribution: A larger base plate distributes the weight over a larger area. The load will be less at risk of grinding both sides of the base plate and sinking into softer ground.

Stability: A properly sized base plate will prevent tilting or tipping on uneven ground.

Compliance with Safety: Correct base plate scaffolding size helps ensure scaffolding is compliant with industry safety standards.

Scaffold Component Longevity: The correct base plate of scaffolding size will reduce wear and tear on all of the individual scaffolding components and the longevity of the scaffold.

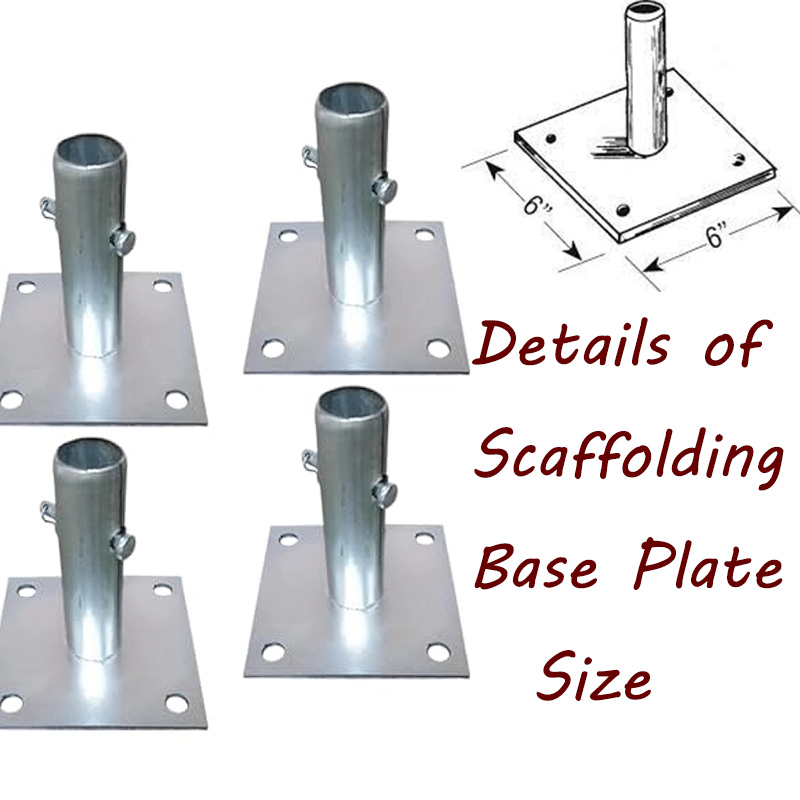

Typical Sizes of Base Plates for Scaffolding

Base plates for scaffolding come in various sizes depending on how much load they are going to carry, the condition of the ground, etc. The following are some standard sizes:

- 150mm x 150mm (6" x 6"): Recommended for light-duty scaffolding on firm, level ground.

- 225mm x 225 mm (9" x 9"): Recommended for medium-duty scaffolding on moderate soft ground.

- 300mm x 300 mm (12" x 12"): Recommended for heavy-duty scaffolding either on ground that is uneven or soft.

Always consult your scaffold design plan and local safety regulations to determine the correct size of the base plate for your scaffold.

Scaffolding Base Plate Types

Fixed Baseplates: Basic scaffold baseplates for scaffolding are standard sizes and shapes. Fixed baseplates are generally only used on flat and stable ground.

Adjustable Base Plate: Adjustable scaffold base plates provide a screw jack mechanism. The adjustable scaffold base plate will allow you to adjust the scaffold height as well as to level the scaffold on uneven ground.

Swivel Base Plates: Swivel base plates work well on slopes or uneven ground. Swivel base plates can rotate to accommodate changes in angle.

Heavy-Duty Base Plates: Heavy-duty scaffold base plates are reinforced base plates for use in high-load and/or harsh environments.

The Role of Adjustable Base Jacks and Sole Boards

A base plate is often welded to an adjustable base jack, allowing precise leveling on uneven terrain.

Adjustable Base Jacks: These provide the necessary vertical adjustment, ensuring the scaffold is perfectly plumb. Crucially, the screw thread extension should be kept to a minimum (typically less than 75% of the maximum thread length) to maintain stability.

Sole Boards (Sole Plates): These are essential for effective load distribution. Even with a sufficiently sized steel base plate, the sole board is the element that dramatically increases the surface area contacting the ground, thus minimizing the risk of the base plate punching through the supporting surface.

Key Factors Influencing Scaffolding Base Plate Size

Determining the appropriate dimensions is not arbitrary. It is a decision driven by engineering principles and site-specific conditions. The following three factors are paramount:

Maximum Expected Load (Weight): The total load a base plate must handle is the sum of the scaffold’s dead load (its own weight) and the live load (workers, materials, tools). Higher anticipated loads require a larger base plate or a more robust footing system to spread the weight over a wider area, thereby reducing the ground bearing pressure.

Ground Bearing Capacity: This is the most critical variable. Soft or unstable ground (e.g., loose soil, fresh fill) has a much lower bearing capacity than concrete or compacted surfaces. A smaller base plate on soft ground will result in excessive settlement or failure. Larger scaffolding base plate dimensions are mandatory when the ground is weak.

Scaffolding System Type: The size and configuration of the scaffold itself (e.g., System Scaffolding, Tube and Coupler) dictates the specific load paths, which in turn influences the required base plate size and the necessity of adjustable base jacks.

More Information on Base Plate Size

Base Plate Size

Ground Conditions

Scaffold Type

Key Features

150mm x 150mm (6" x 6")

Solid, level ground

Light-duty scaffolding

- Compact and lightweight- Ideal for small projects- Easy to install and move

225mm x 225mm (9" x 9")

Moderately soft or uneven ground

Medium-duty scaffolding

- Balanced size for stability- Suitable for most construction sites- Versatile and cost-effective

300mm x 300mm (12" x 12")

Soft, uneven, or sloped ground

Heavy-duty scaffolding

- Maximum load distribution- Ideal for large-scale projects- Enhanced stability on challenging terrain

Adjustable Base Plates

Uneven or sloped ground

All scaffold types

- Screw jack mechanism for leveling- Adaptable to various ground conditions- Ensures perfect alignment

Swivel Base Plates

Sloped or irregular terrain

All scaffold types

- Rotates to accommodate angles- Ideal for slopes or uneven surfaces- Provides flexibility and stability

Notes:

Material: Most scaffolding base plates are made of steel, with galvanized options available for outdoor use to prevent rust.

Load Capacity: Always match the base plate size with the scaffold's load requirements. Larger plates are necessary for heavier loads.

Compliance: Ensure the chosen base plate scaffolding meets local safety standards and regulations.

Guidelines for Safe Use of Scaffold Base Plates

- Always check scaffold components, including the base plates, for damage before using the scaffolding.

- Use adjustable base plate scaffolding on uneven surfaces to keep each base plate and scaffolding level.

- Use a soleboard (timber pads or metal pads) with a base plate to give additional support on soft ground with base plates used.

- Make sure that each base plate at the bottom of the scaffold is tightly affixed to the scaffold standard.

- If working on a long project, regularly check each base plate to ensure everything stays level and stable.

- If using adjustable scaffolding base plates, follow the installation instructions and any local or Standard/Regulation requirements for them.

The Role of Base Plates in Scaffold Systems

The scaffold base plate is a very important piece of a scaffold system, but it is just one part of a scaffold assembly with other parts (standards, ledgers, transoms, and braces). All scaffold parts function, one with another, to complete a safe and stable working platform. If you do not build a scaffold around a properly sized and installed base plate, the scaffold can become unstable, making the working platform unsafe for workers.

Why Choose High-Quality Scaffolding Base Plates?

There are several benefits associated with investing in scaffolding base plates that are of high quality:

Safety: quality scaffolding base plates will reduce the potential for accidents as a result of scaffolding instability

Cost Savings: Quality scaffolding base plates will last longer, reducing replacement costs.

Compliance: Using division-35 base plate scaffolding ensures that the project meets safety codes and regulations.

Flexibility: quality scaffolding is designed to work with a variety of scaffolding systems and conditions on the ground.

Conclusion

Although a scaffold base plate is a relatively small part of the scaffold, it offers enormous stability and safety. Using the right-sized scaffolding base plate effectively can help you develop the working platform you're trying to achieve.

At AJ Building, we carry great quality scaffolding parts, including solid base plates. Contact us to learn more about our different scaffolding base plates and all of our scaffolding parts! We want to build a safe worksite and efficient workspace!

FAQ

What are the standard sizes for scaffolding base plates?

Common sizes include:

150mm x 150mm (6" x 6"): For light-duty scaffolding on solid ground.

225mm x 225mm (9" x 9"): For medium-duty scaffolding on moderately soft ground.

300mm x 300mm (12" x 12"): For heavy-duty scaffolding on uneven or soft terrain.

Why is the size of a scaffolding base plate important?

The size of a scaffolding base plate determines how well it distributes the scaffold's weight. A larger base plate provides better stability, especially on soft or uneven ground, while a smaller one is suitable for solid, level surfaces.

Read More

A Guide to Scaffold Use in the Construction Industry —— Occupational Safety and Health Administration (.gov)

Seven Fundamental Parts of a Scaffold -Avontus® Software— Avontus@ Software