What You Need To Know: Best Wood for Concrete Formwork

Mar 19, 2025

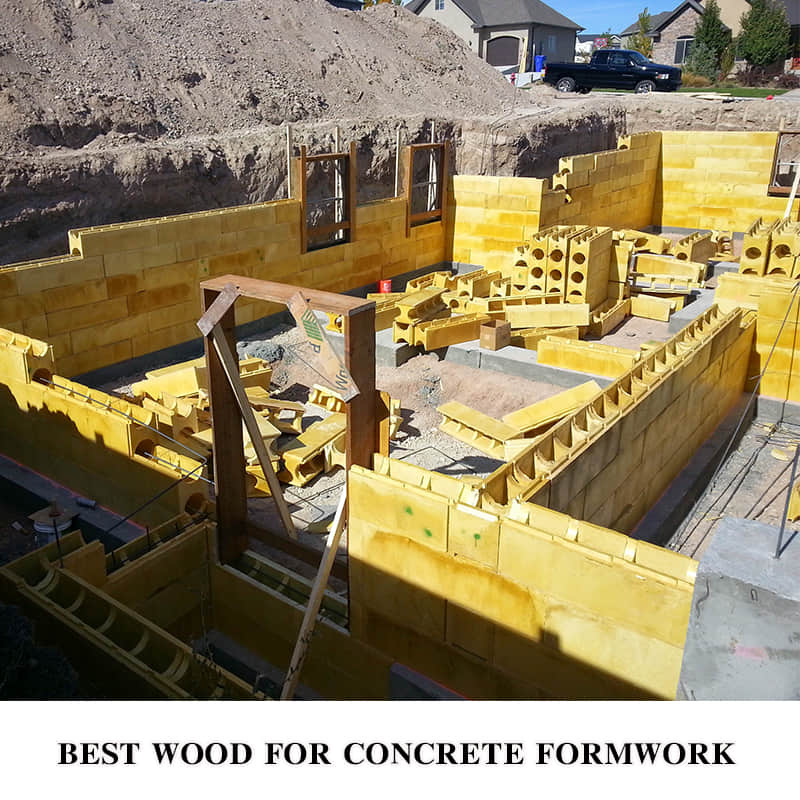

Concrete formwork is defined as the temporary structure that will support and hold the shape of concrete when being poured and curing. The formwork holds everything in place regardless if you are pouring a foundation, wall or even a specially-designed structure; this ensures the concrete cures properly and that you achieve the structural capabilities and finish work you aspire to obtain. In many construction applications wood is a very popular material due to its low cost, availability, and the ease of cutting and assembling.

Nonetheless, wood isn't all created equally. The wood used for concrete formwork must also satisfy specific criteria: it has to be able to support the weight and pressure of wet concrete, provide a smooth surface, remain stable in wet concrete, and allow the forms to be reused to control costs. The right kind of wood can save you time and costs, while the wrong kind of wood can provide you with warped forms, an uneven surface or cause you to spend more money as the forms need to be replaced, etc.

Key Characteristics of the Best Wood for Concrete Formwork

Before we explore specific types of wood, let’s break down the qualities that make a wood suitable for concrete formwork:

Strength and durability: Wet concrete can generate a huge amount of pressure on formwork—sometimes several metric tons per square meter. Because of this, wood must possess sufficient strength to not bend, crack, or break under load.

Smooth surface: To achieve a clean and flat finish on the surface of concrete, the surface of the formwork must be smooth in nature, free from conditions that can cause it to stick or make other issues related to surface finish.

Dimensional stability: Using wood that easily swells, shrinks, or warps from moisture damage will negatively affect the integrity of the concrete and create costly remedies.

Reusable: Formwork can end up being a significant portion of construction cost, therefore the more times wood formwork can be reused, the lower the overall costs of construction can be.

Simple to handle: Construction schedules can be short, therefore wood that can be easily cut, shaped and placed will assist in moving timelines forward.

Types of Wood for Concrete Formwork

1. Plywood: The Versatile Champion

Plywood is the most popular and widely used material for concrete formwork; understandably, it is. Plywood is made of thin layers of wood veneer glued together, and it has strength in many directions, allowing it to withstand the forces of wet concrete. It comes in large sheets, minimizing joints and seams, and is lightweight, not too heavy to be handled on-site.

However, not plywood works for formwork. Only higher grades of plywood are appropriate for concrete; specific plywood like formply is ideal. These types of plywood are often coated in resin or plastic, like phenolic or a high-density overlay, providing excellent water resistance, preventing the concrete from sticking, and giving the form a finished surface. Medium density overlay (MDO) plywood is another type of plywood used for formwork because it is durable and cost-effective.

Pros: Strong, versatile, smooth surface, reusable with proper care.

Cons: Higher-grade plywood can be expensive; lower grades may delaminate or wear out quickly.

2. Softwoods: Budget-Friendly Basics

Softwoods like pine, spruce, and Douglas fir are commonly used for simpler formwork projects. These woods are affordable, widely available, and easy to work with, making them a practical choice for small-scale or one-off jobs. Southern Yellow Pine, in particular, stands out for its strength and availability in certain regions, while Douglas Fir is prized for its stability and load-bearing capacity.

However, softwoods have limitations. They’re less durable than plywood and can warp, split, or absorb moisture unless treated. Pressure-treated softwood lumber can mitigate some of these issues, improving resistance to decay and extending lifespan.

Pros: Cost-effective, easy to cut and assemble, regionally abundant.

Cons: Less durable, prone to warping, limited reusability.

3. Engineered Wood Products: Strength Meets Innovation

Engineered wood, including Laminated Veneer Lumber (LVL), enhances performance to the highest level possible. Made by gluing wood veneers/fibers with adhesives under high pressure, engineered wood products demonstrate remarkable strength, uniformity, and stability. LVL is used, for example, within prefabricated formwork systems where precision and durability are critical.

Even though engineered wood is a great choice for tough applications, its high price tag makes it less common for regular formwork. Engineered wood is a specialized, premium choice for select projects.

Pros: Exceptional strength, outstanding stability, uniformity of quality.

Cons: High cost, overkill for small projects.

Pros and Cons: A Side-by-Side Comparison

Wood Type

Pros

Cons

Plywood

Strong, versatile, smooth finish, reusable

Higher cost for premium grades, lower grades less durable

Softwoods

Affordable, easy to work with, abundant

Less durable, prone to warping, limited reuse

Engineered Wood

Exceptional strength, stable, uniform

High cost, not ideal for small jobs

Which Wood Is Best for Your Project?

The best wood for concrete formwork depends on your project’s scale, budget, and aesthetic requirements. Here are some tailored recommendations:

Large Commercial Projects: High-rise construction or infrastructure projects depend on durability and reuse. High-grade formply or HDO plywood is the best option. The high strength and coated surface functions consistently after each pour, making it cost-effective in the long run.

Small Residential Projects: Building a foundation, or a backyard patio? Specify standard plywood or treated softwood lumber, while still being practical and cost-effective. For smaller pours, the plywood type can provide appropriate support without breaking the bank.

Architectural Concrete: When the concrete's surface is to be exposed (e.g., decorative walls or modern facades), an impeccable finish is non-negotiable. Plywood that is phenolic coated or HDO, provides a smooth mirror-like finish and can also be reused often.

Tips for Maintaining Wooden Formwork

To maximize the lifespan of your wooden formwork, follow these simple steps:

Cleanup after every use: Review the stress on your hand rails. You can brush or rinse out the concrete residue and slab rest after every use. A substrate will build second time around, making it much harder to remove, not to mention, can damage the wood's surface.

Store: Store wood products in dry and shaded conditions, away from the elements. Moisture damage and direct sun exposure to wood will warp the rail.

Release agents: either oil-based or one many commercial release agents are available, should be added before pouring the concrete onto the wood to facilitate release from the wood surface.

Proper care can turn a one-time-use form into a multi-project asset, saving you money over time.

Common Mistakes to Avoid

Even the best wood won’t perform if you cut corners. Watch out for these pitfalls:

When it comes to wood for formwork, beware of low-grade wood or cheap plywood. Although lower-quality wood may save you some transportation, they may not perform well under pressure and could cause the valuable concrete mix to blowout or not be even.

Avoid using untreated or untreated wood. Untreated wood is porous and will absorb moisture from the concrete. This moisture will slowly warp the wood and cause it to weaken over time. Whenever possible, use treated wood, and if it must be untreated, use a protective coating or tape under the fresh concrete.

Look also at the assembly of the form work itself. If you have gaps in the form work, or joints that are weak or do not fit together completely, then the material contained may leak, rendering the project impotent. All forms need to be tight and secured, sealed if necessary, before pouring the concrete.

Cost Considerations: Upfront vs. Long-Term

Price is an essential consideration when evaluating different types of formwork wood. While high-quality plywood or engineered products may cost you significantly more initially, you can reuse them—sometimes up to 20 pours with good care; softwoods or standard plywood are less costly up front but you may have to replace them after a couple of uses or possibly just a single use. When determining the best value, consider the total expected cost based on the total number of pours you are expecting. In the long term, quality wood tends to be the better value—just like furniture or other wood-dependent products, you may pay slightly more for a quality product initially, but high-quality products offer long-term durability and potential dynamic value.

Conclusion

Choosing the appropriate wood for concrete formwork isn't a Holley dilemma—it's about choosing the right application for your job. Plywood is an amazing choice for most projects if you have the correct application in mind with its strength and versatility. Softwoods will fit the bill for most jobs at a more economical price point for less cumbersome work. For critical structural applications, engineered wood can be put to use for high-performance applications. Considering strength requirements, budget, reuse, and finish requirements will optimize your concrete structures to withstand everything and leave the surface smooth and not prone to breaking.

Whether you're pouring a foundation or creating an architectural piece, choosing wisely about your wood will give you a successful project. So the next time you're planning a project for concrete, take a small moment to thoughtfully consider the wood you will use... You will set yourself up and your owners for success, and your budget, time, finished product will thank you for the careful deliberation.

FAQ

Can I use softwoods like pine or spruce for concrete forms?

Yes, softwoods like pine, spruce, and Douglas fir can be used for simple or small formwork projects. However, they are not as durable as plywood and may need to be treated to prevent moisture absorption or warping, making them suitable for budget-conscious or one-time use situations.

Is high-grade plywood worth the investment for concrete forms?

Yes, high-grade plywood can be reused many times (sometimes over 20 pours) with proper care, making it very cost-effective for long-term or large-scale projects. Although the initial cost is higher, its durability usually offsets the expense.

Read More

How To Build Concrete Forms With Plywood ---- Quora

How to Build a Straight Form for Concrete ---- wikiHow