Conventional Formwork Vs Aluminium Formwork

Dec 24, 2024

Conventional Formwork Vs Aluminium Formwork

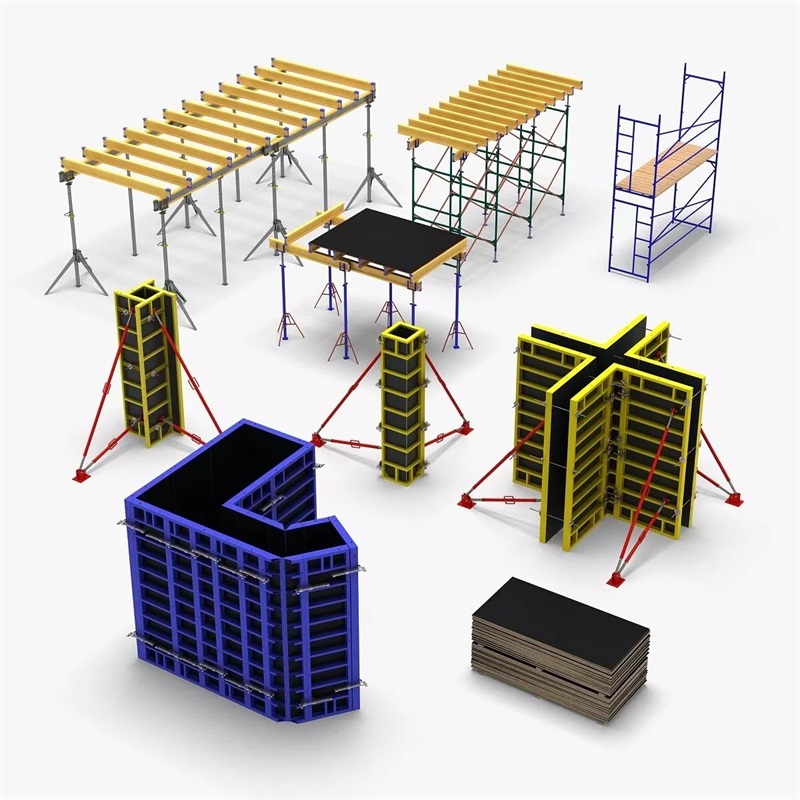

Formwork is among the main supportive structural materials used in construction projects, and hence it has a direct bearing on the efficiency, quality and cost of construction. Various formwork systems can be adopted, among which conventional formwork and aluminum formwork are two common choices. Each of the formwork systems has certain advantages. There are unique advantages and disadvantages of both forms, and this also depends on the specific construction requirements and scales of projects. Knowing the very characteristics of the aluminum formwork and traditional will help the builders in a more needless manner in choosing appropriate choices at planning and implementation stages, thus making progress in building construction, cutting costs and ensuring quality.

A long into the post to complete detailed comparative analysis of speed, cost, sustainability, quality, reusability, safety, etc., between aluminum formwork and conventional formwork, hoping to provide a closer perspective as to what to look for in either. guidance to help in making the right decision that meets the needs of your project.

What Is Conventional Formwork

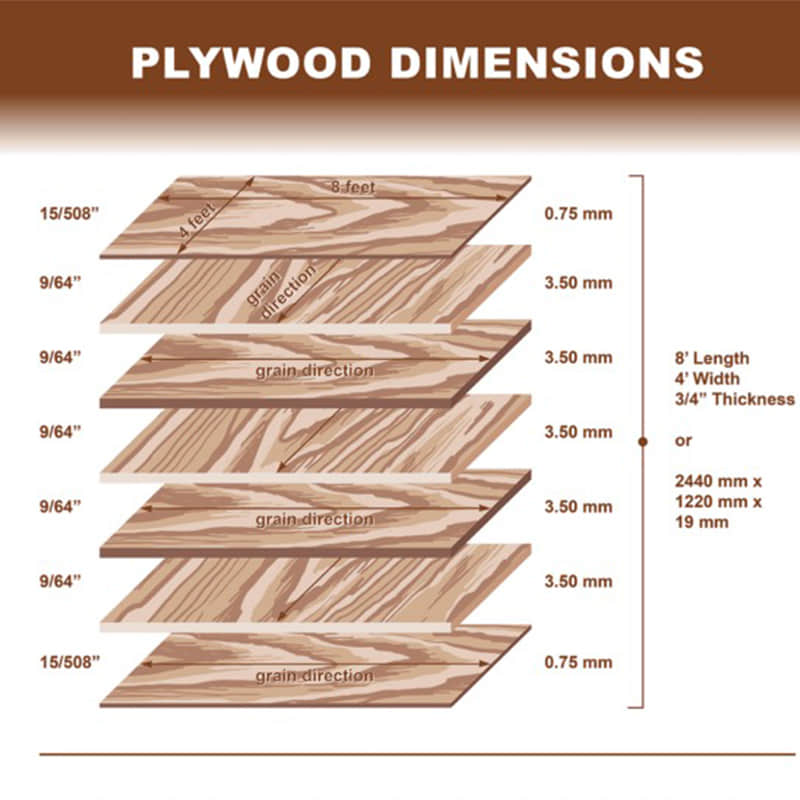

Conventional formwork is mainly made from wood, plywood, moisture-resistant particle board, or steel.

Application

Conventional formwork is used widely in building construction. It is mainly useful in residential buildings, bridges, and low-rise buildings. Wooden formwork can take care of curvilinear and slightly shaped structures. Steel formwork is best for concrete structures that need precision and great strength.

Advantage

Wooden formwork: simple processing, strong adaptability, low price, and easy to make on site.

Steel formwork: high strength, good durability, suitable for large-scale construction, and can withstand high pressure.

Disadvantage

Wooden formwork: easy to deform, short service life, and limited number of reuses.

Steel formwork: heavy, expensive, and requires more equipment and labor for construction.

What Is Aluminum Formwork

Aluminum formwork is a popular formwork used in the construction industry in recent years and is usually made of high-strength aluminum alloys. It provides a modern alternative to traditional methods

Applications Aluminum formwork is mostly used in large commercial buildings, residential projects and high-rise buildings, especially where precision, good surface quality and fast construction are required.

Advantage

Lightweight: Aluminum formwork is lighter than steel formwork, making it easier to carry and install.

Durable: It has good corrosion resistance and wear resistance, and can be reused more times.

High precision: The surface is smooth and can ensure the fineness of the concrete structure.

Save time: easy installation and fast construction.

Disadvantage

Higher cost: The initial investment of aluminum formwork is more expensive than conventional formwork.

Transportation issues: Though light in weight, transport and storage require an adequate amount of planning.

Conventional Formwork Vs Aluminium Formwork

When choosing a formwork, in addition to considering the cost and availability of materials, it is also necessary to conduct an in-depth analysis of various aspects of performance, especially in terms of speed, cost, sustainability, quality, reusability, safety, etc. The following is a comparative analysis based on typical construction projects, combining common data and standards in the industry.

1. Speed

Aluminum formwork :

Installation time: Aluminum formwork is quick to install due to its modular and lightweight design. It only takes 1 to 1.5 hours to install one square meter of aluminum formwork on average, which is particularly suitable for construction projects that need to be completed efficiently and quickly. In some large projects, the installation speed can reach more than 200 square meters per day.

Disassembly time: The disassembly time of aluminum formwork is shorter than that of conventional formwork, usually 0.5 to 1 hour per square meter, and it can be moved quickly.

Conventional Formwork :

Installation time: The installation of wooden and steel formwork is relatively slow. Wooden formwork needs to be cut and adjusted on site, and the average installation time is 2 to 3 hours per square meter. Although steel formwork is more stable than aluminum formwork, it is heavier and requires more labor, and the installation time is usually 1.5 to 2 hours per square meter.

Disassembly time: Disassembly of wooden formwork encompasses an entirely different time scale. Wooden formwork usually takes from 1.5 to 2 hours for disassembly, while steel formwork needs from 1 to 1.5 hours for disassembly.

2. Cost

Aluminum formwork :

Initial cost: The initial investment in aluminum formwork is relatively high. Usually, the price per square meter of aluminum formwork is between $60-100 (depending on the region and manufacturer). For a 1,000 square meter project, the initial investment may reach $60,000 to $100,000.

Long-term costs: Despite the high initial investment, aluminum formwork is extremely durable and reusable. After multiple uses, the cost per use is greatly reduced, and the average cost per use can be reduced to 5-10 US dollars per square meter. If the aluminum formwork is used more than 200 times, the average cost can be reduced to 1-2 US dollars per square meter.

Conventional Formwork :

Wooden formwork: The initial cost of wooden formwork is low, usually $5-10/m2. For a 1,000 m2 project, the initial investment in wooden formwork is only $5,000 to $10,000. However, wooden formwork can only be used 4 to 6 times and needs to be replaced after each use, so the long-term cost is high.

Steel formwork: The initial cost of steel formwork is lower than that of aluminum formwork, about $50-80/m2, but due to its heavy weight and limited number of uses, the long-term cost is also higher. Steel formwork can usually be used 50 to 100 times, so the cost per use is between $10 and 20/m2.

3. Sustainability

Aluminum formwork :

Aluminum formwork is highly sustainable, and the material itself is recyclable. Aluminum formwork has a long service life and can usually be used more than 200 times. After each use, the aluminum formwork can still maintain high strength and an intact condition, reducing resource waste.

Aluminum has a high recycling rate and can be reused after recycling, reducing the impact on the environment.

Conventional Formwork :

Wooden formwork is poor. Wood can usually only be used 4-6 times, and wooden formwork will have a certain degree of loss after each use, and cannot be reused for a long time. In addition, the disposal of wooden formwork will involve the consumption of forest resources and environmental pollution.

Steel formwork is slightly less sustainable than aluminum formwork, but it is more sustainable than wood formwork because it can be used multiple times ( 50-100 times ). Steel formwork itself can be recycled, but it is heavier and uses more energy than aluminum formwork.

4. Quality

Aluminum formwork :

Aluminum formwork has high precision and can provide a smooth concrete surface. The corrosion resistance of aluminum alloy material makes the formwork less likely to deform during construction, thus ensuring the quality of the concrete structure.

Due to the precise design of the aluminum formwork, the concrete is of high precision during construction, making it suitable for high-demand construction projects such as high-rise residential buildings and commercial buildings.

Conventional Formwork :

Wooden formwork is prone to uneven surfaces and strong water absorption, which may affect the surface quality of concrete. Especially in a humid environment, wooden formwork is prone to deformation, resulting in defects in the concrete structure.

Steel formwork is better, but due to its heavy weight, it may cause certain precision errors during installation, especially when splicing on site.

5. Reusability

Aluminum formwork :

Aluminum formwork is highly reusable, and each formwork can be used more than 200 times, greatly reducing the cost of material replacement during long-term construction.

The aluminum formwork is very easy to disassemble, clean, and maintain, can be efficiently reused, and is suitable for large-scale reuse.

Conventional Formwork :

Wooden formwork has poor reusability and can generally only be used 4 to 6 times. In addition, damaged parts need to be inspected and replaced after each use, which increases the cost of repair and replacement.

Steel formwork is more reusable than wooden formwork and can usually be used 50 to 100 times, but it is also limited by factors such as usage conditions and maintenance conditions.

6. Security

Aluminum formwork :

The aluminum formwork is light in weight, which reduces the difficulty of manual handling during installation and disassembly, and reduces the risk of worker injury.

Due to its fine structure, the aluminum formwork has high stability and is not easily deformed or damaged during disassembly.

Conventional Formwork :

Wooden formwork is light in weight and easily damaged during operation, which may increase safety hazards during construction.

Steel formwork is heavy and requires more equipment for handling and operation, which increases the safety risks during operation.

The Real Cost Comparison: Initial vs. Long-Term ROI

A common misconception is that conventional formwork is always cheaper. While the initial purchase price of an aluminium system is higher, a comprehensive cost analysis reveals a superior long-term Return on Investment (ROI) for aluminium.

Aspect

Conventional Formwork (Timber/Plywood)

Aluminium Formwork System

Initial Cost

Low. Material is inexpensive and readily available.

High. Custom, high-strength aluminium alloy.

Reusability

Limited (20–30 times). Prone to warping, damage, and wear.

High (200–300+ times). Highly durable and non-corrosive.

Labor Cost

High. Requires more hours and highly skilled labor for fabrication and maintenance.

Low. Reduced hours and lower-skilled labor required for assembly/stripping.

Waste & Safety

High material waste; higher risk of on-site injury from heavy lifting and sharp edges.

Minimal material waste; lightweight design enhances site safety and reduces fatigue.

Long-Term ROI

Low, due to high replacement costs and slow cycle times.

High, due to amortization over hundreds of uses and significant time savings.

In Conclusion

Through detailed comparative analysis, aluminum formwork has shown obvious advantages in speed, cost, quality, reusability, safety, and sustainability, and is particularly suitable for large-scale, high-precision, and high-reuse projects. Although its initial cost is higher, it has a good long-term return on investment and is ideal for construction projects that require high construction quality and speed.

Conventional formwork (wood formwork and steel formwork) has certain advantages in cost control and is suitable for projects with lower budgets or smaller scales. Although the initial cost of wooden formwork is low, its reusability is poor, and the long-term cost is high; steel formwork provides a good compromise in reusability and quality.

In general, choosing the right formwork is not a simple cost consideration, but a comprehensive assessment of the project's scale, budget, construction requirements, environmental conditions, and construction period.

FAQ

Why is aluminum formwork more expensive than conventional formwork?

The initial cost of aluminum formwork is higher, mainly because it uses high-strength aluminum alloy materials, and its sophisticated design and manufacturing process require more costs. In addition, the transportation, storage, and maintenance of aluminum formwork are also more complicated than conventional formwork. However, the long-term use and reusability of aluminum formwork greatly reduce the cost of a single construction, so it has a higher cost-effectiveness in the long run.

How reusable are aluminum formworks?

Aluminum formwork is highly reusable. Typically, aluminum formwork can be reused more than 200 times, and each time it is used, the formwork still maintains a high-quality standard. This makes aluminum formwork very economical and sustainable in long-term projects. Traditional wooden formwork is usually only used 4-6 times, while steel formwork can be reused 50-100 times.

Read More

Conventional Formwork-Established Formwork Methods --- RESEARCHGATE

Types Of Modern Construction Formwork --- SLIDESHARE