Difference Between Commercial and Residential Construction

May 24, 2025

The world of construction is vast and varied, encompassing everything from towering skyscrapers to cozy family homes. While both fall under the broad umbrella of "construction," commercial and residential projects are fundamentally different beasts. Understanding these distinctions is crucial for clients, contractors, investors, and anyone involved in the building process. This comprehensive guide will delve into the key differences between commercial and residential construction, exploring everything from design and materials to regulations and project management.

Commercial Construction Scope

Business & Corporate: Office buildings, data centers.

Retail & Service: Stores, shopping centers, restaurants, banks, salons.

Hospitality: Hotels, resorts, convention centers.

Industrial: Factories, warehouses, distribution centers.

Healthcare: Hospitals, clinics, larger assisted living facilities.

Institutional & Public: Schools, government buildings, libraries, museums, airports, sports arenas.

Large-Scale Multi-Family Residential: Large apartment complexes, mixed-use developments with significant residential components.

Residential Construction Scope

Single-Family Homes: Detached houses (custom, tract).

Small Multi-Family Dwellings: Duplexes, triplexes, townhouses, small apartment buildings.

Accessory Dwelling Units (ADUs): Granny flats, in-law suites.

Home Renovations & Additions: Major remodeling and extensions.

Purpose and Scope: The Fundamental Divide

The most apparent distinction lies in the purpose and scope of the projects:

Residential Construction: Focuses on creating living spaces. This includes single-family homes, duplexes, townhouses, and smaller apartment buildings. The primary goal is to provide comfort, functionality, and a personalized environment for individuals and families. The scope is generally smaller, though luxury custom homes can be complex.

Commercial Construction: Encompasses a broader range of structures built for business or public use. This includes office buildings, retail stores, warehouses, industrial facilities, hospitals, schools, hotels, and large multi-family residential complexes (often with mixed-use components). The emphasis is on functionality, durability, capacity to accommodate a high volume of people, and return on investment. Commercial projects are typically larger in scale and complexity.

Design and Complexity: Function Meets Aesthetics

Design philosophies and structural complexities vary significantly:

Residential Design: Often emphasizes aesthetics, comfort, and the homeowner's personal preferences. Layouts are designed for daily living, with considerations for family needs, natural light, and flow. While architects are involved, especially in custom homes, designs can sometimes be more standardized (e.g., tract housing). Structural systems are typically simpler, often utilizing wood framing.

Commercial Design: Prioritizes functionality, efficiency, and the specific needs of the business or occupants. This might involve large open-plan offices, specialized retail layouts, heavy-duty industrial flooring, or intricate MEP (mechanical, electrical, and plumbing) systems for hospitals or labs. Architects and engineers play a central role in designing complex structures that can withstand heavy use and meet specific operational requirements. Steel framing and reinforced concrete are common due to the larger scale and load-bearing necessities.

Building Codes and Regulations: A Stricter Landscape for Commercial

Navigating building codes and regulations is a critical aspect of any construction project, but the requirements differ substantially:

Residential Building Codes: Primarily focus on safety, habitability, and energy efficiency for occupants. Regulations like the International Residential Code (IRC) govern aspects such as structural integrity, fire safety, plumbing, electrical, and insulation. While thorough, these codes are generally less stringent and complex than their commercial counterparts. Permitting processes are typically more straightforward.

Commercial Building Codes: Are significantly more rigorous and multifaceted due to public safety concerns, accessibility requirements (e.g., Americans with Disabilities Act - ADA), and the potential for higher occupancy loads. Codes like the International Building Code (IBC) cover a wider array of considerations, including advanced fire suppression systems, robust emergency egress routes, structural stability for larger loads, specific ventilation requirements, and often, more demanding energy efficiency standards. The permitting process for commercial projects is usually longer and involves multiple layers of approval from various authorities.

Materials and Equipment: Durability and Scale in Focus

The choice of materials and the type of equipment used reflect the differing demands of each sector:

Residential Materials: Commonly include timber for framing, asphalt shingles for roofing, vinyl siding, and standard drywall. While quality and durability are important, cost-effectiveness for the homeowner is often a key driver.

Residential Equipment: Involves smaller, more versatile machinery like skid steers, mini-excavators, and standard power tools.

Commercial Materials: Often necessitate more durable and heavy-duty materials. Steel for framing, concrete for foundations and structures, EPDM or TPO roofing systems, curtain wall systems, and commercial-grade finishes are prevalent. These materials are chosen for their longevity, strength, and ability to withstand high traffic and usage. Fire-rated materials are also a critical consideration.

Commercial Equipment: Requires larger, more specialized, and heavy-duty machinery. This includes cranes, bulldozers, heavy excavators, concrete pumps, and sophisticated surveying equipment. The scale of commercial projects demands equipment capable of handling substantial loads and extensive site work.

Equipment Needs: Scaffolding and Formwork

For scaffolding and formwork rental companies, this is the most critical distinction. The scale of the project dictates the machinery and temporary structures required.

Residential Equipment

Low-Complexity Scaffolding: Often utilizes simple frame scaffolding or pump-jack systems.

Light Machinery: Skid steers and mini-excavators usually suffice.

Formwork: Basic wood or light metal forms for foundation walls.

Commercial Equipment

Commercial projects operate on a different magnitude, requiring specialized heavy-duty solutions:

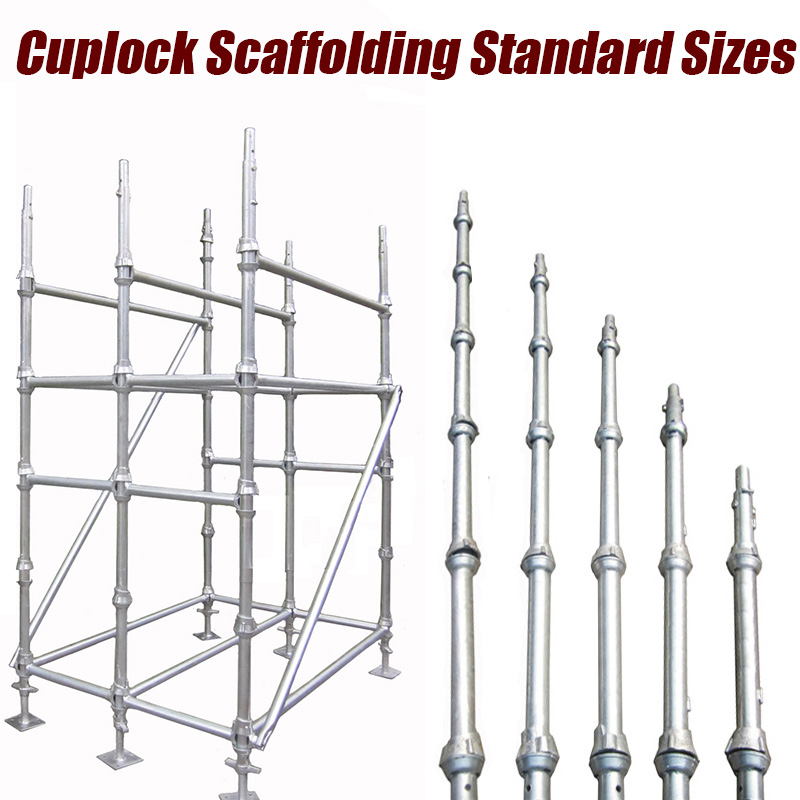

Engineered Scaffolding: High-rise projects require suspended scaffolding, mast climbers, and heavy-duty modular systems (like Ringlock or Cuplock) designed to support heavy loads and withstand high wind pressures at elevation.

Cranes: Tower cranes are a staple for moving steel beams and concrete buckets.

Advanced Formwork: Large-scale commercial builds utilize climbing formwork systems, table forms, and robust steel shuttering to handle the immense pressure of pouring concrete for multi-story cores and columns.

Project Timelines and Management: Complexity Drives Duration

The duration and management of construction projects also showcase clear differences:

Residential Timelines: Are generally shorter. Building a standard single-family home might take several months to a year. Project management is often less complex, involving fewer stakeholders (homeowner, builder, and a few subcontractors).

Commercial Timelines: Are typically much longer, often spanning several years for large or complex projects. This is due to the intricate design phases, extensive approval processes, complex construction sequences, and the coordination of numerous specialized subcontractors (e.g., for HVAC, electrical, plumbing, fire protection, data cabling).

Commercial Project Management is a highly specialized field requiring sophisticated planning, scheduling, cost control, and communication among a diverse team of architects, engineers, contractors, subcontractors, and often, client representatives or investors. Building Information Modeling (BIM) is increasingly used in commercial projects for better coordination and visualization.

Costs and Funding: A Different Financial Scale

The financial aspects of commercial and residential construction are distinct:

Residential Costs: While significant for an individual homeowner, are generally lower per square foot compared to commercial projects. Funding typically comes from personal savings, mortgages, or construction loans specifically designed for homeowners.

Commercial Costs: Are substantially higher due to the larger scale, more robust materials, complex systems, stringent code requirements, longer timelines, and higher labor costs associated with specialized trades.

Commercial Funding: Is often more complex, involving a wider range of sources. These can include corporate financing, commercial real estate loans, private equity investment, real estate investment trusts (REITs), and sometimes government funding or incentives. The financial stakes and risk profiles are considerably higher.

Labor and Expertise: Specialized Skill Sets

The workforce and expertise required also differ:

Residential Labor: Often involves general contractors who manage a team of subcontractors specializing in home building trades like carpentry, plumbing, and electrical work for residential systems.

Commercial Labor: Demands a higher degree of specialization and is often unionized labor. Crews are typically larger and include experts in steel erection, concrete work, commercial-grade HVAC and electrical systems, data infrastructure, and specialized finishes. Project managers and site supervisors in commercial construction usually have extensive experience with large-scale projects.

Conclusion

While both commercial and residential construction aim to create functional and safe structures, they operate under vastly different parameters. Commercial construction is characterized by its larger scale, higher complexity, stricter regulations, focus on durability and public use, and more intricate funding and management processes. Residential construction, on the other hand, is typically smaller in scope, more personalized, and governed by less complex (though still critical) codes, with a primary focus on creating comfortable living spaces.

Recognizing these fundamental differences is essential for anyone venturing into a construction project, whether as a client seeking to build a dream home or an investor planning a new business facility. By understanding the unique challenges and requirements of each sector, stakeholders can make more informed decisions, set realistic expectations, and ultimately contribute to the successful completion of their construction endeavors.

Ready to elevate your next project?

Whether you are planning a complex commercial high-rise or a residential development, you need partners who understand the unique demands of your build. Contact us today to discuss our premium range of construction materials and heavy-duty equipment rental solutions tailored to your specific sector.

FAQ

What is the main difference between commercial and residential buildings?

The main difference is their purpose and use. Commercial buildings are used for business activities and to generate profits, while residential buildings are used to house people. This leads to significant differences in design, materials, regulations, construction processes, and financial considerations.

Does commercial construction cost more than residential construction?

Usually, yes. Commercial construction typically costs much more per square foot than residential construction due to design complexity, material costs, stricter codes, specialized labor, and longer construction times.

Read More

What Makes a Property a Commercial Real Estate Property? —— TRESSLER

Is multifamily considered residential or commercial? —— Multifamily