How Much Weight Should Scaffolding Be Able To Support

Sep 28, 2023

Scaffolding is an integral part of construction and maintenance projects, providing access to elevated work areas. Understanding the weight capacity of scaffolds is not only crucial for safety but also for the success of any project. In this article, we'll explore the factors that influence scaffold weight capacity, the types of scaffolds and their load limits, safety measures, and more to help you determine how much weight a scaffold can hold.

Types of Scaffolds & Their Weight Capacities

Scaffold weight limits vary depending on the type and intended use. Below are some common scaffold types and their typical load capacities:

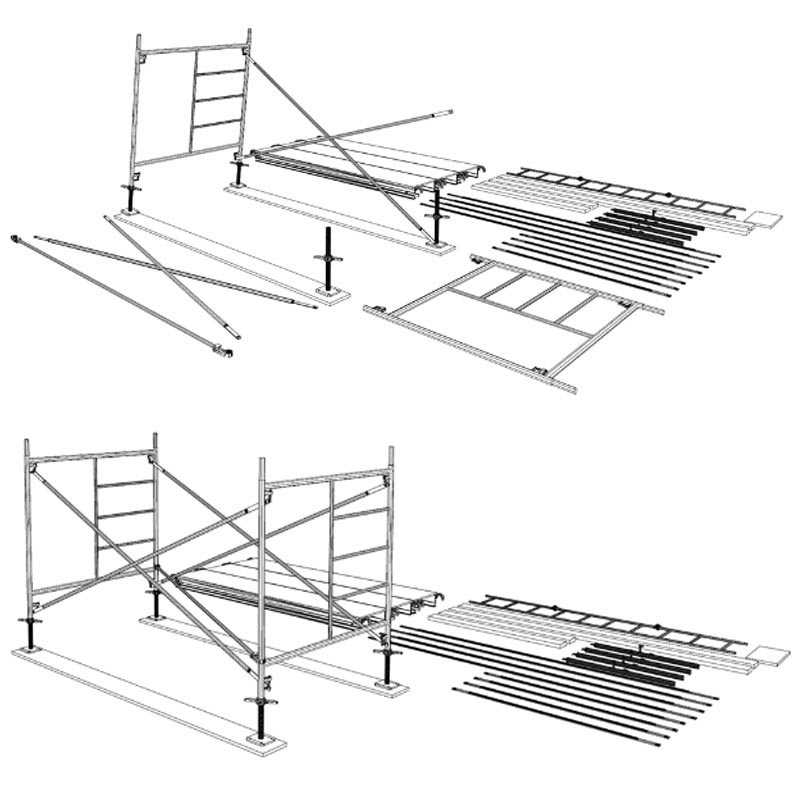

1. Supported Scaffolds (Frame Scaffolds)

Description: These are the most common scaffolds, consisting of a framework supported by vertical posts.

Weight Capacity: Typically rated for light-duty (25 lbs/sq ft), medium-duty (50 lbs/sq ft), or heavy-duty (75 lbs/sq ft) loads.

Use Case: Ideal for construction, masonry, or painting projects.

2. Suspended Scaffolds

Description: Hung from ropes or cables, often used for high-rise building maintenance or window cleaning.

Weight Capacity: Varies widely, from 250 lbs to 1,000 lbs, depending on the platform size and suspension system.

Use Case: Best for tasks requiring access to tall structures.

3. Mobile Scaffolds

Description: Equipped with wheels for easy movement, often used in indoor or small-scale projects.

Weight Capacity: Generally lower, ranging from 500 lbs to 1,500 lbs, due to mobility constraints.

Use Case: Suitable for maintenance or repair work in confined spaces.

4. Tube and Coupler Scaffolds

Description: Customizable scaffolds built with tubes and clamps, offering flexibility in design.

Weight Capacity: Can be engineered for heavy-duty loads, often exceeding 75 lbs/sq ft when properly designed.

Use Case: Used in complex or large-scale construction projects.

Frame Scaffolds

Tube and Coupler Scaffolds

Modular System Scaffolds

Suspended Scaffolds

OSHA and Industry Standards for Load Classification

To standardize safety across the industry, regulatory bodies like the Occupational Safety and Health Administration (OSHA) in the US and similar organizations worldwide have established load classifications for scaffolding. These classifications are based on the scaffold's maximum intended load per square foot (or kg per square meter) of the work platform.

Here's a breakdown of the standard categories:

Scaffolding Class

Maximum Intended Load (per square meter)

Typical Uses

Light-Duty

120 kg/m² (~25 lbs/ft²)

Ideal for light maintenance, painting, and inspection work involving minimal materials and tools.

Medium-Duty

240 kg/m² (~50 lbs/ft²)

Suitable for bricklaying, plastering, and general construction where multiple workers and materials are present.

Heavy-Duty

360 kg/m² (~75 lbs/ft²)

Designed for stone masonry, heavy concrete work, and projects requiring significant storage of heavy materials and equipment on the platform.

How to Calculate the Total Load on Your Scaffold

To ensure you don't exceed the scaffold's capacity, you need to calculate the total weight you plan to place on it. This is your intended load.

Weight of Personnel: Add the approximate weight of all workers who will be on the scaffold at the same time.

Weight of Tools and Equipment: Include the weight of all hand tools, power tools, and other equipment like welders or mixers.

Weight of Materials: This is often the heaviest component. Calculate the weight of bricks, blocks, buckets of mortar, or any other supplies you will be placing on the platform.

Total Intended Load = (Weight of Workers) + (Weight of Tools) + (Weight of Materials)

Once you have this total, you can determine if it falls within the capacity of your scaffold's duty rating for the given work area.

Safety Standards for Scaffold Load Capacity

To ensure safety, scaffold weight capacities are regulated by standards such as:

OSHA (U.S.): Requires scaffolds to support at least 4 times the intended load without failure. For example, a scaffold rated for 500 lbs must withstand 2,000 lbs in testing.

BS EN 12811 (Europe): Specifies load classes ranging from Class 1 (0.75 kN/m²) to Class 6 (6 kN/m²), depending on the scaffold’s purpose.

AS/NZS 1576 (Australia/New Zealand): Similar to OSHA, mandates a safety factor of 4:1 for load-bearing components.

Always check the manufacturer’s specifications and local regulations before loading a scaffold.

Factors that Influence Load-Bearing Capacity

Scaffold Type and Design: Different types of scaffolds have varying weight capacities based on their design and intended use. Frame scaffolds, tube and coupler scaffolds, and system scaffolds all have unique load-bearing capabilities.

Material Used in Scaffolding: The materials used in constructing the scaffold play a significant role in determining its load capacity. Steel scaffolds typically have higher load capacities compared to aluminum or wooden scaffolds.

Configuration and Setup of the Scaffold: The way the scaffold is configured and set up, including the number of levels, bracing, and additional support like outriggers, can affect its weight capacity. Proper setup according to manufacturer guidelines is essential.

Load Distribution and Categories: Scaffolds must support two types of loads: live loads (people, equipment, materials in use) and dead loads (the weight of the scaffold itself). Properly distributing these loads is critical to avoid overloading.

Formulas For Scaffolding Load Capacity

When it comes to the calculation of the scaffolding capacity, one uses the following formula:

Q = P × A

Q = the overall capacity of the scaffold in kilograms or pounds;

P = maximum load carrying capacity in kg per square meter or lb/sq ft, which the manufacturer of the scaffold must provide;

A = the whole area of the scaffold platform in square meters or square feet.

Tips for Safe Scaffold Use

Inspect Regularly: Check for damaged components, loose connections, or unstable ground before use.

Distribute Weight Evenly: Avoid concentrating heavy loads in one area of the platform.

Use Guardrails and Fall Protection: Ensure workers are protected from falls, especially on high scaffolds.

Train Workers: Provide training on scaffold safety, load limits, and proper usage.

Avoid Overloading: Never exceed the scaffold’s rated capacity, as this can lead to collapse or injury.

Common Mistakes to Avoid

Avoiding these common mistakes is crucial when working with scaffolds:

Overloading scaffolds beyond their weight capacity.

Neglecting proper scaffold setup and bracing.

Failing to follow safety precautions and regulations.

Safety First: Best Practices for Scaffold Loading

Always prioritize safety over speed. Adhering to these best practices will help prevent dangerous overloads.

Know Your Rating: Never use a scaffold without knowing its duty rating.

Inspect Daily: Before each work shift, a competent person must inspect the scaffold for any signs of damage or instability.

Don't Hoard Materials: Only bring the materials you need for the immediate task onto the scaffold. Remove them once you're done.

Distribute Weight Evenly: Spread materials and workers out as much as possible to avoid concentrating the load in one area.

Never Drop Loads: Dropping heavy items onto the scaffold can create an impact load far greater than the item's static weight, potentially exceeding the 4-to-1 safety factor.

When in Doubt, ask: If you are unsure about the load capacity or proper use of a scaffold, consult with a qualified person or the supplier.

Conclusion

Proper scaffolding load calculation is not just a regulatory requirement; it is a fundamental aspect of risk management and a commitment to worker safety. For construction and engineering firms, it ensures project efficiency and avoids costly failures. For scaffolding and formwork companies, it is the cornerstone of a reliable and trustworthy service.

By meticulously following manufacturer specifications, conducting accurate calculations, and considering all influencing factors, you can ensure that your scaffolding system provides a safe and stable working environment, supporting your team and your project to its full potential.

FAQ

Can I exceed the weight limit temporarily?

No, exceeding the weight limit of a scaffold, even temporarily, can compromise safety and lead to accidents. Always stay within the specified weight capacity.

Are there regulations for scaffold weight limits?

Yes, there are safety regulations and standards that govern scaffold weight limits. Compliance is essential to ensure a safe work environment.

What should I do if I suspect a scaffold is overloaded?

If you suspect a scaffold is overloaded, immediately remove excess weight, and do not use the scaffold until it has been inspected and deemed safe by a qualified professional.

Read More

General Guide For Scaffolds -- SAFEWORK

Scaffold Checklist-Construction -- HSE

Scaffold Safety -- EHS